Remote monitoring system for bioreactor

A remote monitoring system and bioreactor technology, applied in the program control and electrical program control of the sequence/logic controller, can solve the problems of long-term sterilization and disinfection, inconvenient, and increased pollution risks, and achieve saving Effects of time, space reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

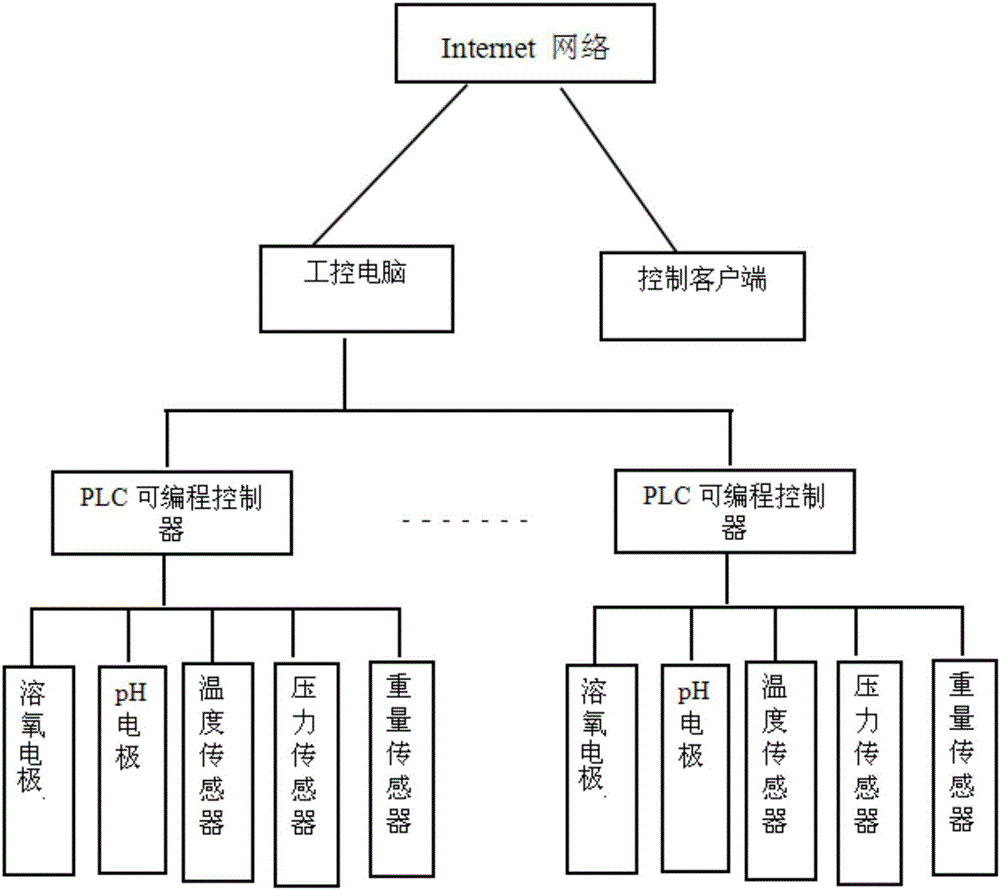

[0032] refer to figure 1 As shown, this embodiment discloses a bioreactor remote monitoring system, which mainly includes a bottom monitoring subsystem, a bottom monitoring control subsystem, an industrial computer, an Internet network, and a control client.

[0033] The above-mentioned underlying monitoring subsystem is actually composed of several sensors or monitoring modules, which are installed on the bioreactor to monitor the real-time response signal of the above-mentioned bioreactor and collect real-time parameter signals of the bioreactor.

[0034] The above-mentioned underlying monitoring and control subsystem is a PLC programmable controller, the above-mentioned PLC programmable controller is connected to the above-mentioned underlying monitoring subsystem, and the above-mentioned underlying monitoring subsystem transmits the response signal obtained in real time to the above-mentioned PLC programmable controller, and the above-mentioned PLC The controller transmits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com