Automatic butt assembling method for large part as well as system

A technology of automatic docking and assembly method, applied in assembly machines, complex mathematical operations, instruments, etc., can solve the problems that the actual parameters cannot be completely matched with the design parameters, cannot be assembled at one time, and are not taken into account, so as to avoid errors and ensure Quality and success rate, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

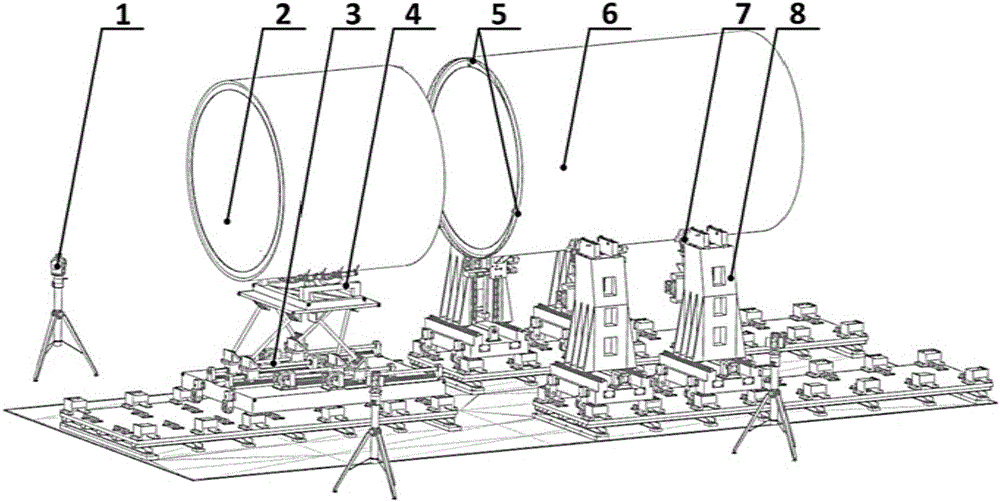

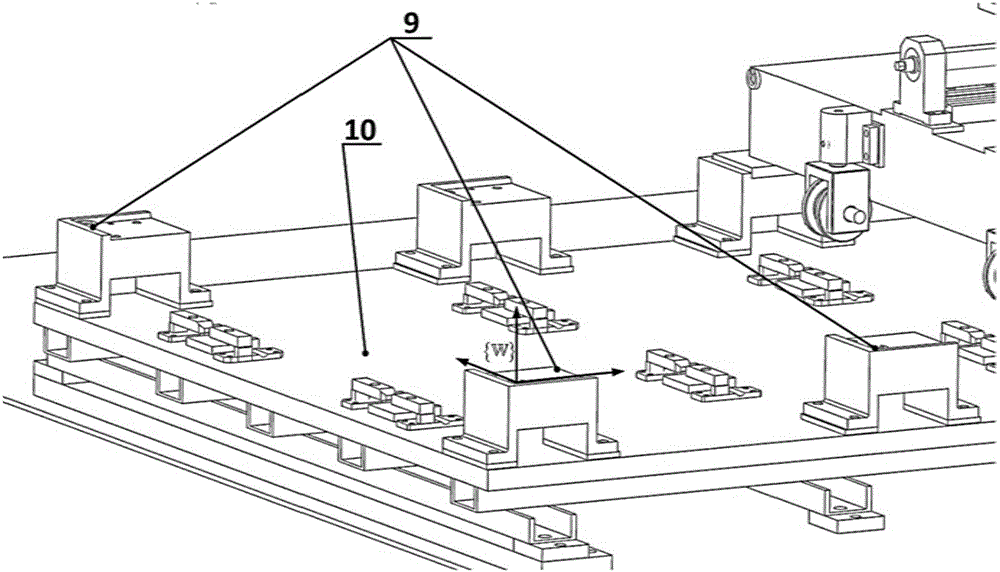

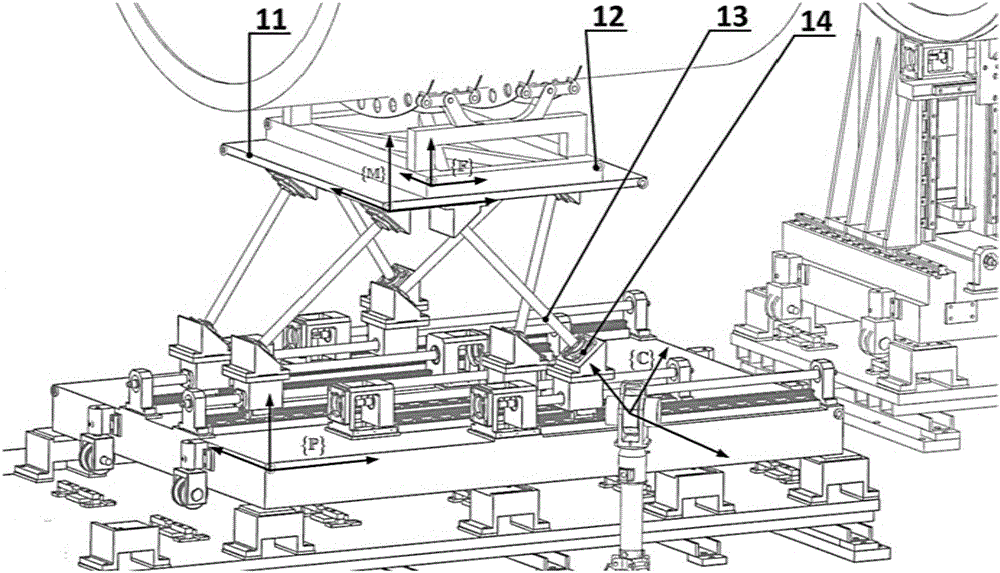

[0044] like figure 1 As shown, this embodiment includes: a parallel servo attitude adjustment positioner 3, a tower servo attitude adjustment positioner 8, a control module and a laser tracker 1, wherein: a parallel servo attitude adjustment positioner 3 and a tower servo attitude adjustment positioner 8. Relatively arranged on the base 10, the laser tracker 1 is arranged around the base 10 to measure the first docking part 2, the second docking part 6, the parallel servo attitude adjustment positioner 3 and the tower servo attitude adjustment positioner 8. After receiving the position information, the control module sends the drive amount information of each axis to the parallel servo attitude adjustment positioner 3 and the tower servo attitude adjustment positioner 8 .

[0045] The parallel servo attitude adjustment positioner 3 is used for loading the docking cylinder section as the first docking part 2 , and the tower servo attitude adjustment positioner 8 is used for loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com