Design method for inflow channel of cyclone grit basin with trapezoid cross section

A technology of swirl grit chamber and design method, applied in the directions of calculation, instrument, geometric CAD, etc., can solve the problems affecting the sand removal efficiency of swirl chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

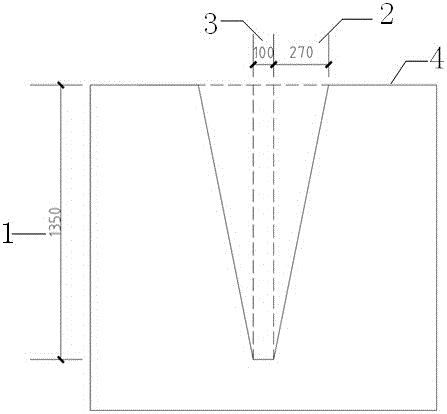

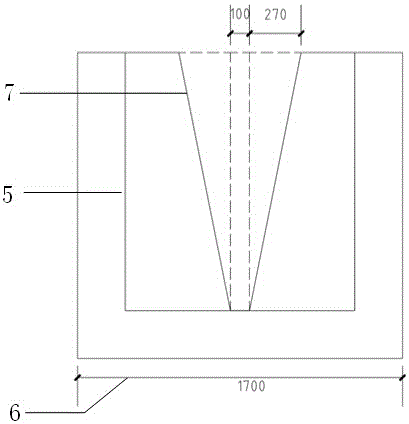

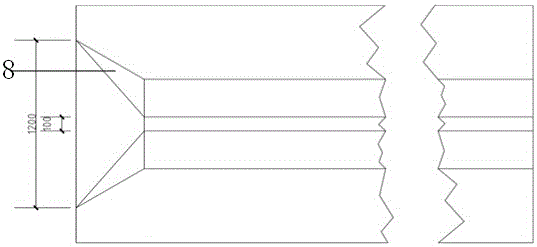

[0027] A sewage plant, the average flow rate of the cyclone grit chamber is 25000m 3 / d, the coefficient of variation is calculated as 1.4, then the daily minimum flow Q min =25000 / 1.4=17860m 3 / d, the maximum daily flow Q max =25000×1.4=35000m 3 / d, rainstorm coefficient 1.6, handling capacity during rainstorm: Q max =25000×1.6=40000(m 3 / d). Therefore, the influent flow Q min =17860m 3 / d,Q max =40000m 3 / d is used as the design flow rate to design the water inlet channel of the cyclone grit chamber. According to the particle size range of the influent particles, the bulk density of the influent, the roughness of the influent channel and other factors, the optimum influent velocity range is determined as: 0.39m / s~0.94m / s.

[0028] Design specifications and requirements to be met:

[0029] In the "Quick Design Manual for Water Supply and Drainage (2) - Drainage Engineering", the flow velocity of the water inlet channel is stipulated as 0.6-0.9m / s at 40%-80% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com