A preparation method of an RFID tag embedded in a packaging substrate by hot stamping

An RFID label, using bronzing technology, applied in the field of RFID electronic label production, processing and application technology, can solve the problems of slow speed, loss of anti-counterfeiting, traceable RFID labels, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

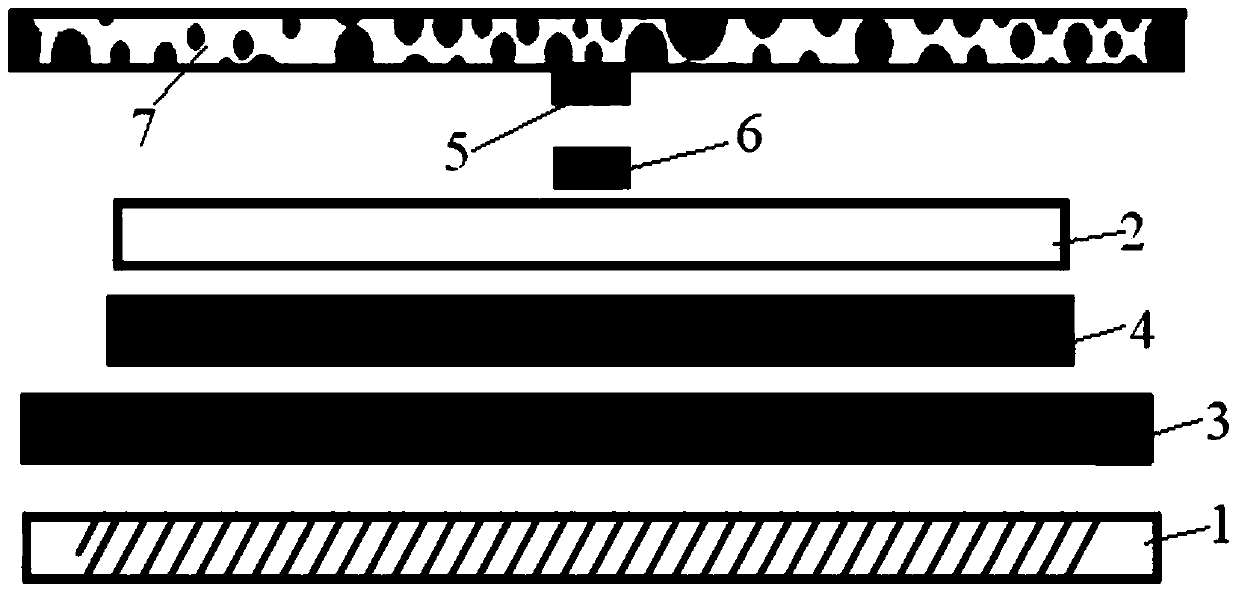

[0026] The structure of the RFID label inserted into the packaging substrate using the hot stamping method provided in this embodiment is as follows: figure 1 As shown, it includes at least a PET substrate 1, an antenna metal layer 2 and a chip 5, a peeling layer and a composite adhesive layer are arranged above the PET substrate, the antenna metal layer is fixed on the top of the composite adhesive layer, and the chip is bonded by conductive adhesive On the antenna metal layer, a layer of pressure-sensitive adhesive layer or hot-melt adhesive layer is arranged on the antenna metal layer, which is hot-melt adhesive in this embodiment.

[0027] In this embodiment, the manufacturing process and insertion process of an RFID tag suitable for cigarette c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com