Coal-bed gas well multi-coal seam combined drainage and mining technique evaluation method

A technology for coalbed methane wells and evaluation methods, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as insufficient production capacity of coalbed methane development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An evaluation method for coalbed gas well multi-coal seam joint drainage technology, based on the analysis of previous drilling, well logging, well testing and fracturing technology data, sequentially through single factor, multi-factor weight analysis judgment and comprehensive evaluation to judge the feasibility of combined bed drainage .

[0029] Further, the method contains the following steps:

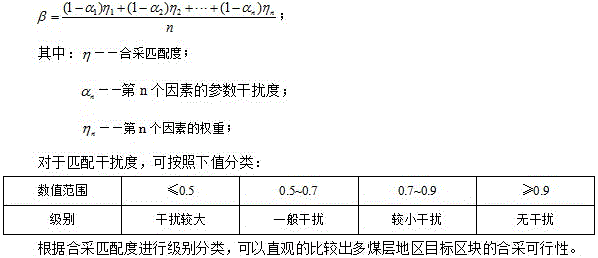

[0030] Step 1: According to the analysis of drilling, well testing, logging and fracturing data of the target coal seam in the target area, determine the main reservoir parameters that affect the combined drainage and production, and conduct a single factor analysis of the impact of combined drainage on each reservoir parameter degree.

[0031] Step 2: According to the degree of influence of each reservoir parameter on productivity, it is compared and weighted.

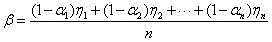

[0032] Step 3: By setting the parameters of the matching degree of joint mining, comprehensively analyze wheth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com