IGBT module assembly

A component and cold plate technology, applied in the field of IGBT module components, can solve problems such as electrical safety accidents, achieve the effect of preventing electrical safety accidents, avoiding short circuits between electrodes, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

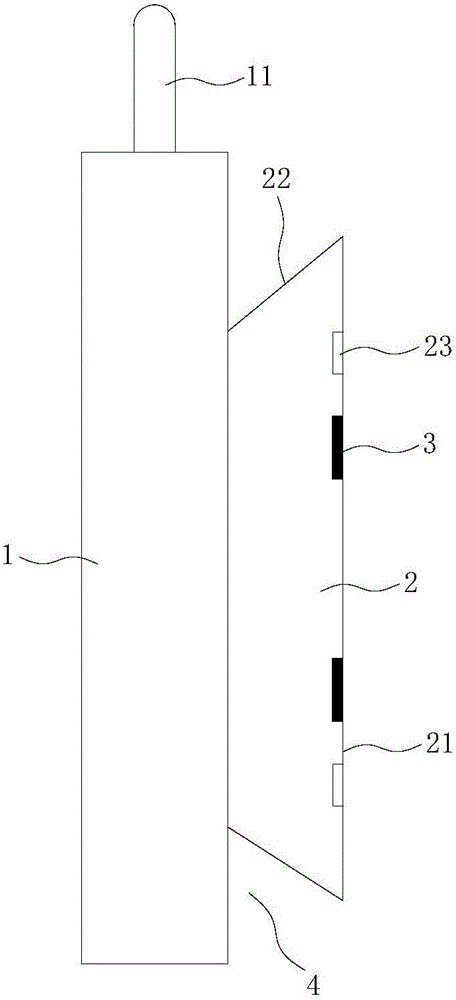

[0034] In this embodiment, on the basis of Embodiment 1, the structure of the water guide groove 4 is further improved, specifically, as Figure 4 As shown, in this embodiment, a semicircular open groove 5 is provided on the side 22 of the IGBT module 2 near the end of the cold plate 1, and the water guide groove 4 is formed together through the open groove 5 and the cold plate 1. When the condensed water accumulates, it can pass through The above-mentioned water guiding groove 4 directly flows out of the IGBT module 2 . By providing the opening groove 5, when the IGBT module assembly is placed vertically, the condensed water will flow into the water guide groove 4 formed by the opening groove 5 and the cold plate 1 along the surface and side 22 of the cold plate 1, and will not flow into the IGBT module 2. On the end surface 21 where the connection terminal 3 is located.

[0035] The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com