Light energy-saving and environment-friendly shoe soles

An energy-saving, environment-friendly and light-weight technology, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of technical setting lag, etc., and achieve the effect of compact technical structure and obvious comprehensive economic and social benefits of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

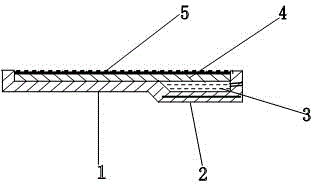

[0012] as attached figure 1 Shown, the light weight energy-saving environmental protection sole of the present invention, it comprises front sole 1, rear heel 2, heel inner capsule 3, chaff layer 4, massage layer 5 five parts,

[0013] The front sole 1 is arranged on the front end of the rear heel 2 and the lower side of the chaff layer 4, and its main function is to support the chaff layer 4;

[0014] The rear heel 2 is arranged on the rear end of the front sole 1 and the outer side of the heel bag 3, and an anti-penetration layer is sandwiched in the heel sole and an injection valve (not shown in the figure) is attached to the heel side, and its main function is to accommodate Heel inner bag 3 and support the rear end of the sole;

[0015] The heel inner bag 3 is arranged on the inner side of the heel 2 and the lower side of the chaff layer 4, and its main function is to fill with gas, colloid, liquid or set solid;

[0016] The bran powder layer 4 is arranged on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com