Dust collector, dust cup device and multi-conic cyclone assembly

A multi-cone and cyclone technology, which is applied in the direction of vacuum cleaners, suction filters, exhaust diffusers, etc., can solve the problems of low filtration efficiency of vacuum cleaners, achieve simple and reasonable structural design, improve filtration capacity, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present invention clearer, the vacuum cleaner, the dust cup device and the multi-cone cyclone assembly thereof of the present invention will be further described in detail through the following embodiments in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

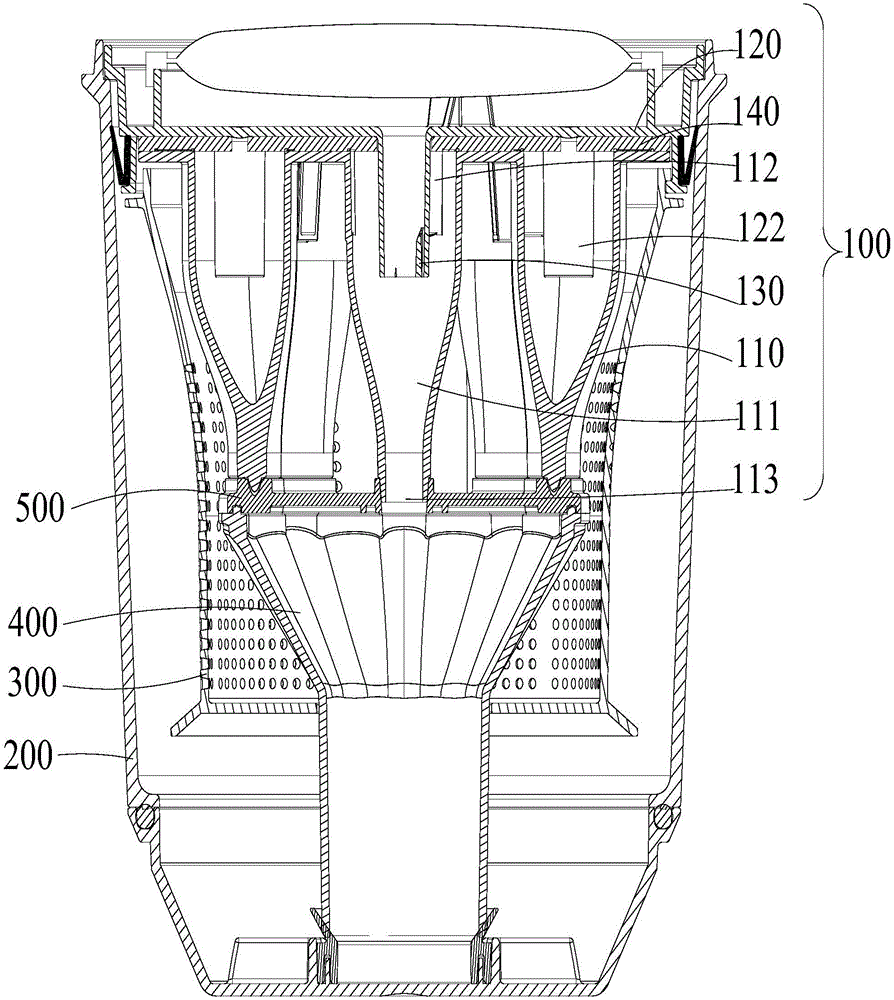

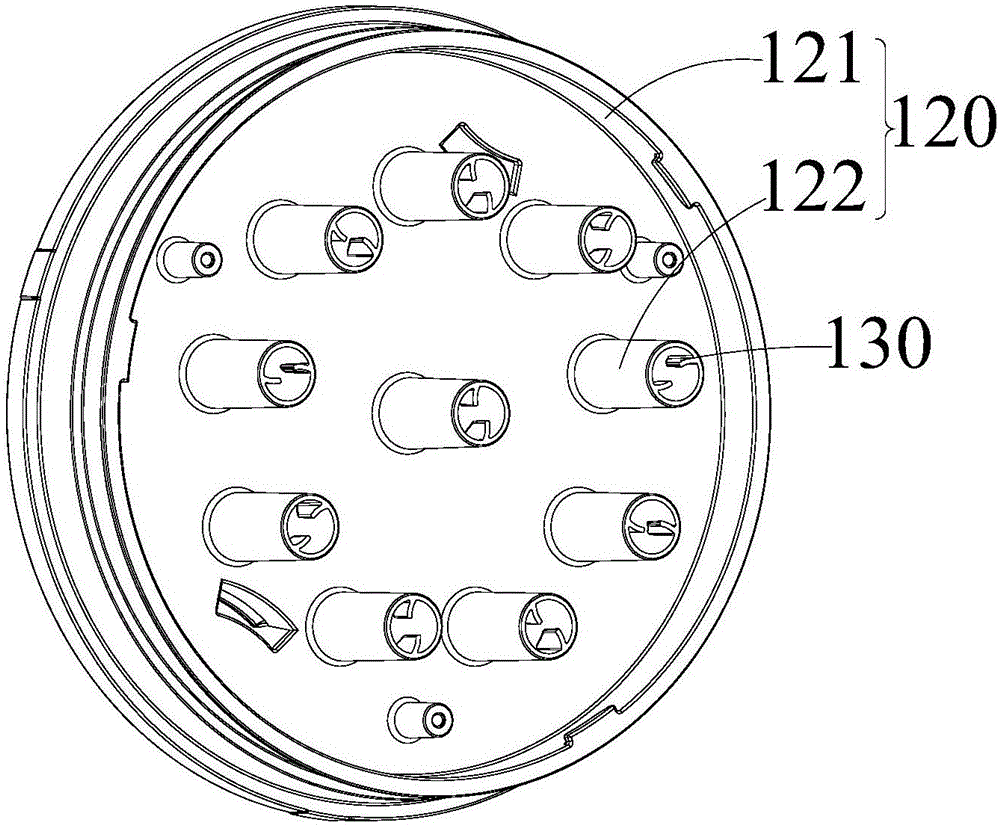

[0048] see Figure 1 to Figure 4 , the present invention provides a multi-cone cyclone assembly 100, which is applied to a vacuum cleaner, can improve the filtration efficiency of the vacuum cleaner, improve the performance of the vacuum cleaner, enhance market competitiveness, and be convenient for users to use.

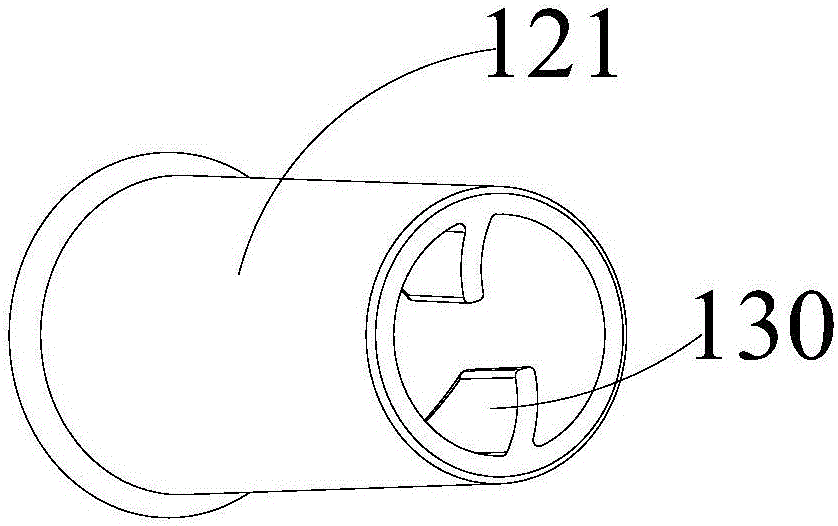

[0049] In the present invention, the multi-cone cyclone assembly 100 includes a multi-cone 110 , a cyclone 120 and a plurality of spoilers 130 . The poly-cone 110 is used to separate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com