Method for forming turbine blade through round bar multi-directional die forging

A steam turbine blade and multi-directional die forging technology, which is applied to the multi-directional die forging of small blade forgings and the field of multi-directional die forging of round bar materials to form steam turbine blades, and can solve the problem of low material utilization and numerous process steps in the free forging manufacturing process To achieve the effect of improving the controllability of product quality, reducing production processes, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

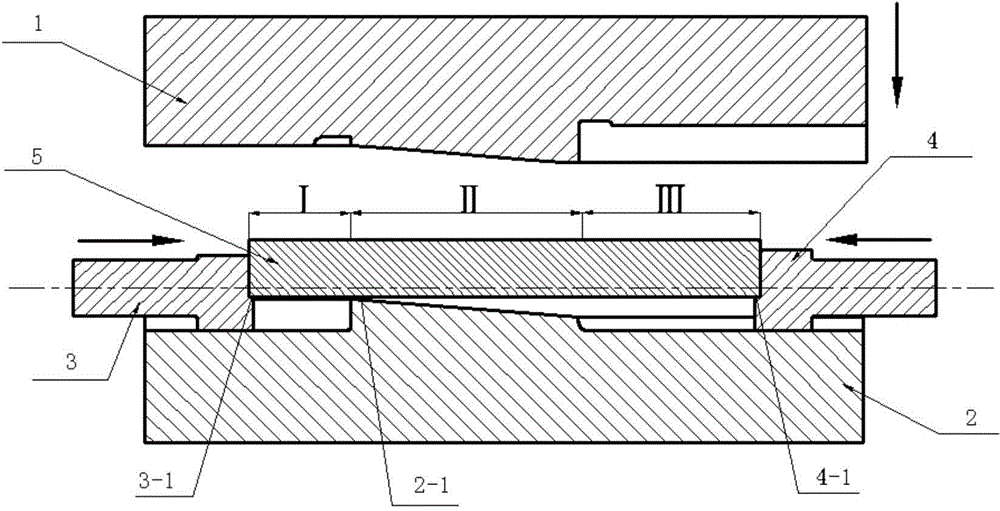

[0035] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0036] The present invention adopts a process method for forming a small blade forging of a steam turbine by heating and die-forging a round rod-shaped blank at one time, which is realized through the following steps:

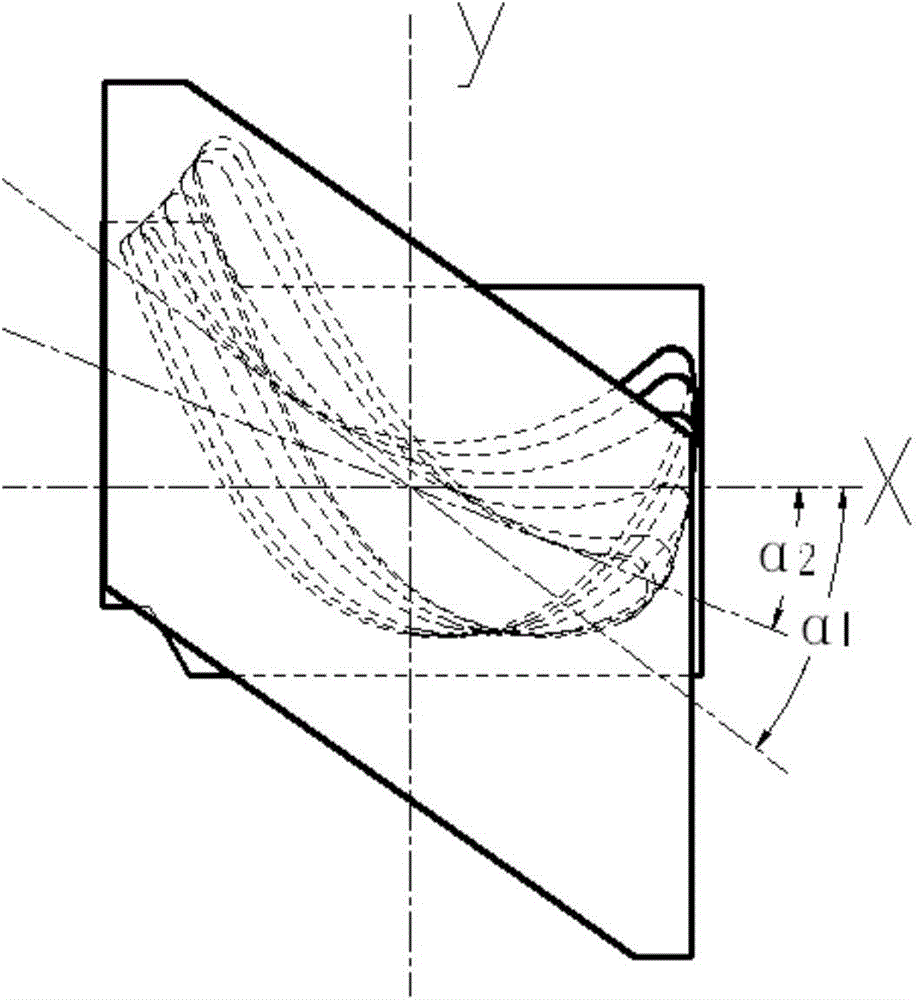

[0037] (1) Design the forging drawing according to the blade parts drawing, the design blade body one-way allowance is 1.5mm~3.5mm, and the one-way allowance of the blade body section near the blade root is close to 1.5mm, preferably 1.5mm, which is close to the blade. The one-way allowance of the blade section of the top part is close to 3.5mm, preferably 3.5mm, and the forging allowance of the rest can be taken close to 2.5mm, preferably 2.5mm. Based on this, draw the forging drawing, such as figure 1 As shown, the three-dimensional model of blade forgings is established by modeling software;

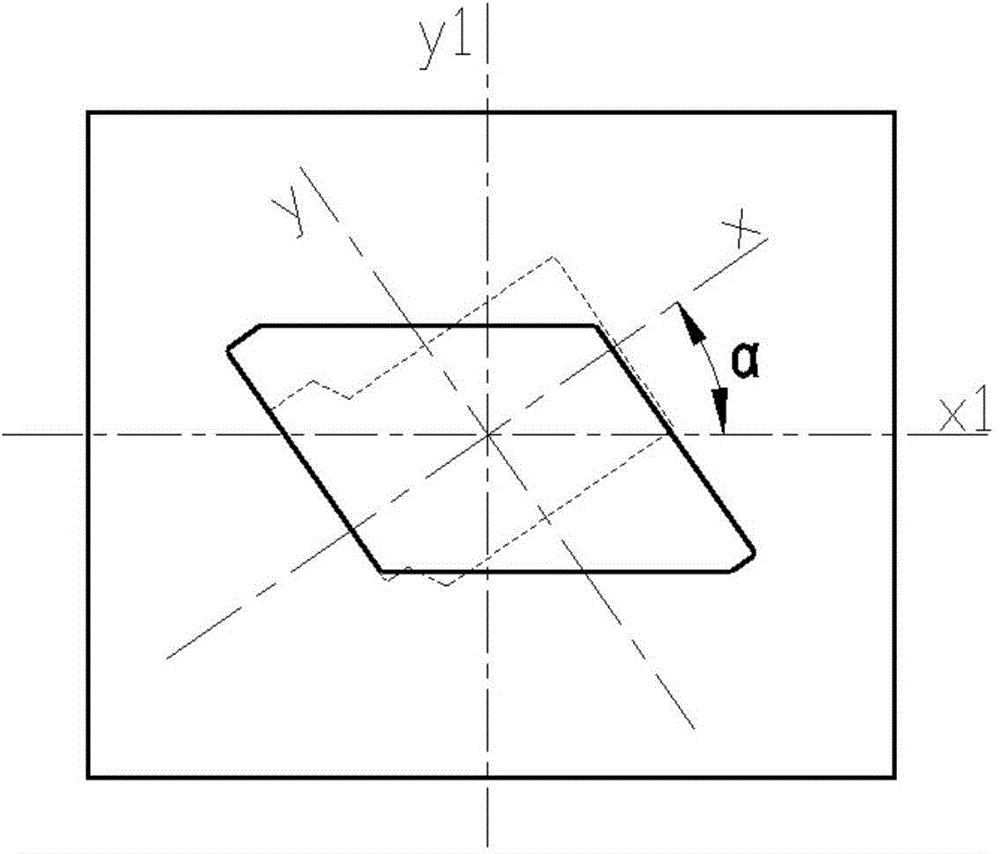

[0038] (2) In the coordinate system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com