Manufacturing method for tower damper

A manufacturing method and damper technology, applied in the field of damper manufacturing, can solve the problems of deviation of optimal frequency design value, lack of practical application, inconvenient manufacture of tower dampers, etc., and achieve the effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The number of tower floors of the Ping An Financial Center project is 118 floors, and the height of the main structure is 558.45 meters. The tower dampers of the present invention are respectively arranged in two cylinders located at the northwest and southeast corners of the core cylinder on the L113-L115 floors.

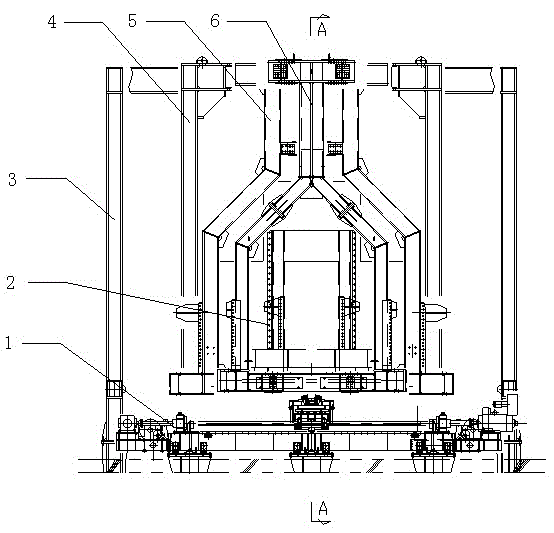

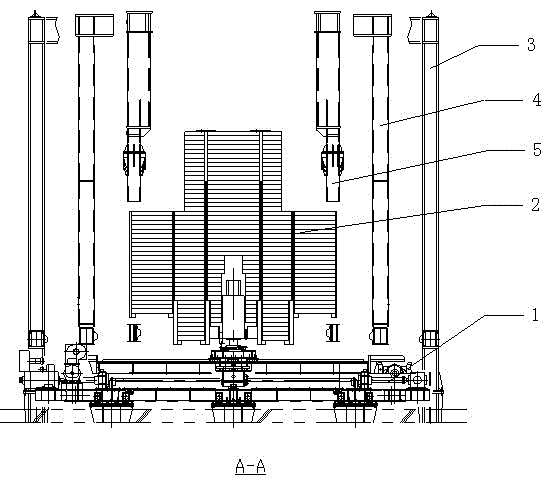

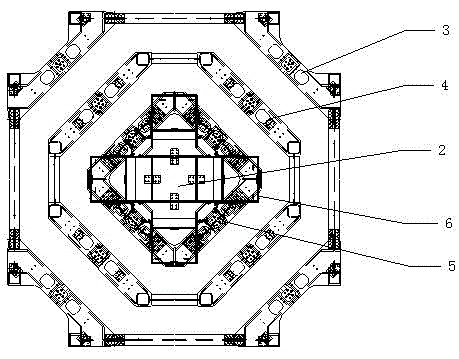

[0050] see now figure 1 , figure 1 figure 1 It is a structural schematic diagram of a tower damper according to an embodiment of the present invention; figure 2 for figure 1 A-A sectional view in ; image 3 It is a plane layout diagram of the tower damper of the embodiment of the present invention.

[0051] Figure 4 Make a process flow chart for the components of the tower damper in the embodiment of the present invention. Figure 5 It is a component layout diagram of the tower damper according to the embodiment of the present invention.

[0052] The manufacture method of tower damper of the present invention is characterized in that comprising the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com