Fast convenient energy-saving environment-friendly baking-free brick mold

An energy-saving, environment-friendly, non-fired brick technology, applied in molds, etc., can solve problems such as technical lag, and achieve the effects of extremely low production cost, obvious promotion and use effect, and exquisite technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

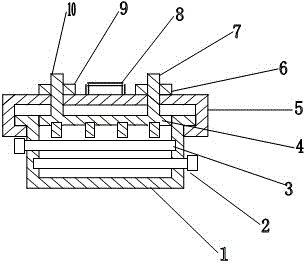

[0015] As shown in the accompanying drawings, the fast, energy-saving and environment-friendly mold-making of unburned bricks of the present invention includes two parts, the main part and the accessories, and its main features are:

[0016] The main body includes a main mold body 1, a lower pass rod 2, an upper pass rod 3, a pressure orifice plate 4, a fastening plate 5, a right pressure rod 7, a left pressure rod 10,

[0017] The main mold body 1 is arranged on the outside of the pressure orifice plate 4 and the outer edge of the upper edge, and is provided with a raised ridge to interlock with the concave ridge on the lower side of the outer edge of the fastening plate 5, and the left, right, upper, lower, and upper sides are respectively provided with a connecting rod 3, The through hole through which the lower through rod 2 passes and the left and right inner side walls are respectively provided with a lower blind hole supporting the end of the lower through rod 2 and an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com