Crawler-type transfer device

A crawler-type, rotating connection technology, applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., can solve problems such as poor flexibility, and achieve the effect of improving utilization, flexible docking, and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

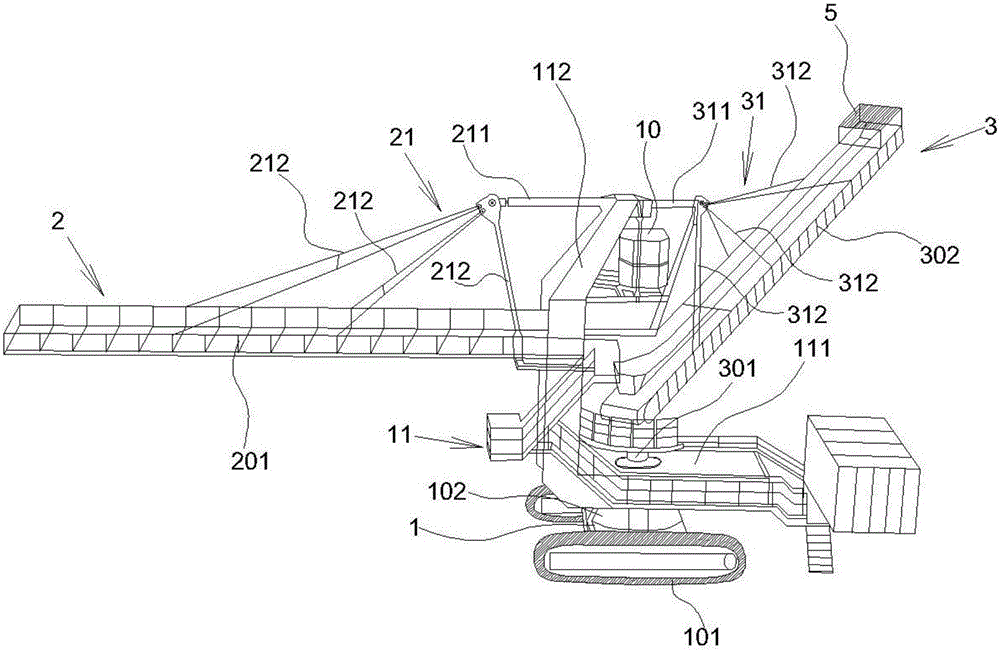

[0025] figure 1 It schematically shows a crawler-type reloading device according to an embodiment of the present invention, which is suitable for conveying various loose materials such as lumps and granules, and realizes rapid supply from one conveying device to another in the storage yard. It solves the technical situation that the conveying equipment cannot continuously convey when the positions of the feeding point and the receiving point are constantly changing.

[0026] Such as figure 1 As shown, a crawler-type reloading device provided by the present invention includes a control platform 1 and a material conveying assembly 11 and a control system 10 arranged on the control platform 1 . Wherein, the feeding mechanism 2 and the discharging mechanism 3 are movably connected to the feeding assembly 11, the feeding mechanism 2 is connected with the discharging mechanism 3, and the output end of the feeding mechanism 2 is located above the input end of the discharging mechani...

Embodiment 2

[0037] The structure of a crawler-type reloading device provided in the second embodiment of the present invention is basically the same as that of the crawler-type reloading device provided in Embodiment 1. The first pitching mechanism 21 and the second pitching mechanism 31 in this kind of crawler-type reloading device are hoisting mechanisms, including a hoisting machine, stay ropes and pulleys, and the stay ropes are respectively connected to the upper two ends of the feeding mechanism 2 and the discharging mechanism 3. and the positions on both sides of the middle part, the pulleys are arranged on the top of the support 112, and the winch is arranged beside the control system 10, and the operation is controlled by the control system 10, and the stay ropes connected with the feeding mechanism 2 and the discharging mechanism 3 go around the pulleys and are connected with the winch , control the pitching of the feeding mechanism 2 and the discharging mechanism 3 through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com