Online stroboscopic detection and automatic splicing device for composite equipment

A compounding equipment and automatic splicing technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve problems such as product quality cannot be guaranteed, the running speed of the compounding machine is disturbed, and the operation of the compounding machine is not synchronous, etc., to avoid problems such as Forms the effect of interference, material saving, and small labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

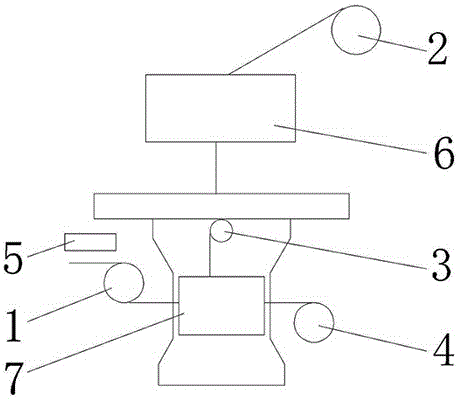

[0020] like figure 1 As shown, an online stroboscopic detection and automatic splicing device for composite equipment in this embodiment includes a first guide roller 1, a second guide roller 2, a third guide roller 3, a winding roller 4, a strobe Instrument 5, paper storage device 6 and splicing device 7.

[0021] The connection method of each component is as follows: the front end of the first guide roller 1 is provided with a stroboscope 5, a paper storage device 6 is provided between the second guide roller 2 and the third guide roller 3, the first guide roller 1, the third guide roller The rollers 3 are all connected to the winding roller 4 through the splicing device 7; the surface of the stroboscope 5 is provided with a strobe detection lamp, and connected to the external controller; the paper storage device 6 includes nine groups of paper guide rollers and Drive rollers, the splicing device 7 includes pressing rollers, an automatic phase control system and a cutter dr...

Embodiment 2

[0025] like figure 1 As shown, an online stroboscopic detection and automatic splicing device for composite equipment in this embodiment includes a first guide roller 1, a second guide roller 2, a third guide roller 3, a winding roller 4, a strobe Instrument 5, paper storage device 6 and splicing device 7.

[0026] The connection method of each component is as follows: the front end of the first guide roller 1 is provided with a stroboscope 5, a paper storage device 6 is provided between the second guide roller 2 and the third guide roller 3, the first guide roller 1, the third guide roller The rollers 3 are all connected to the winding roller 4 through the splicing device 7; the surface of the stroboscope 5 is provided with a strobe detection lamp, and connected to the external controller; the paper storage device 6 includes nine groups of paper guide rollers and Drive rollers, the splicing device 7 includes pressing rollers, an automatic phase control system and a cutter dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com