A kind of graphene composite coating, graphene composite coating and preparation method thereof

A graphene composite, graphene technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor coating protection effect, easy to agglomerate, etc., achieve good water permeability, inhibit surface adsorption, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a preparation method of graphene composite coating. The method comprises the steps of:

[0030] Step (1): Disperse the aniline oligomer and graphene in a dispersion medium, mix the aniline oligomer and graphene uniformly and form a π-π bond between the aniline oligomer and graphene to obtain a graphene dispersion . The aniline oligomer has good solubility and can be dissolved in the dispersion medium. The aniline oligomer is used to modify the graphene. Specifically, since the benzene ring in the aniline oligomer is similar in structure to graphene, the aniline oligomer can form a π-π bond with graphene to achieve uniform mixing with graphene. It should be pointed out that the formation of π-π bonds between aniline oligomers and graphene is different from chemical grafting modification, which does not destroy the structure of graphene itself, and is also different from physical coating of graphite. Graphene polymers w...

Embodiment 1

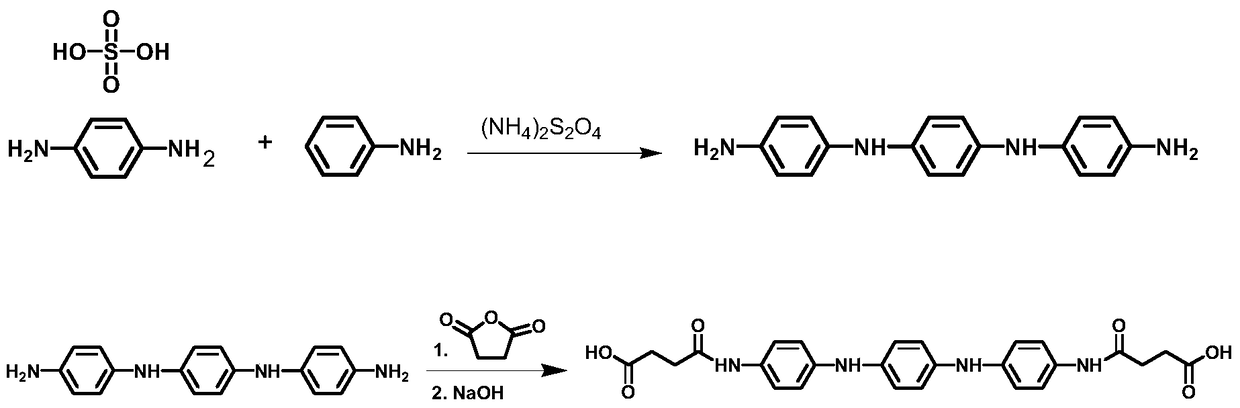

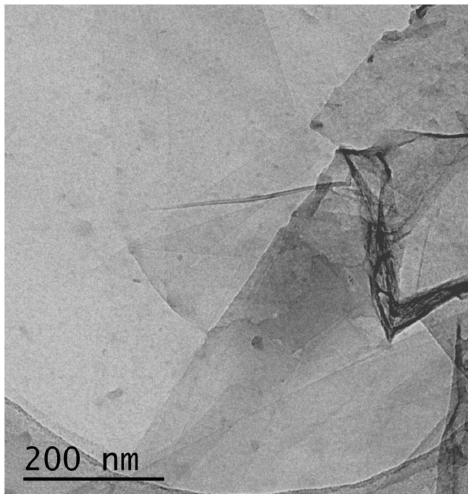

[0041] With 1.0g aniline trimer (synthetic process sees figure 1 ) and 1.0 g of graphene (purchased from Ningbo Moxi Technology Co., Ltd.) were dispersed in 1.0 L of toluene solution and ultrasonically dispersed for 1 hour to obtain a graphene dispersion. The content of graphene in toluene after modified by aniline trimer reaches 1g / L. The comparative effect of described graphene dispersion liquid and untreated graphene after toluene dispersion sees figure 2 . The electron transmission electron micrograph of described graphene dispersion liquid sees image 3 . Depend on figure 2 and image 3 It can be seen that graphene can be uniformly dispersed in toluene after being modified by aniline trimer, and the graphene in the graphene dispersion liquid has a sheet-like structure.

[0042] The graphene dispersion was added to 45 g of epoxy resin (model E44, purchased from Jiangsu Wujiang Heli Resin Factory), and mixed to obtain mixture A. Then add 2g leveling agent, 4g defoa...

Embodiment 2

[0044] 2.0 g of aniline tetramer and 1.0 g of graphene were dispersed in 1.0 L of toluene solution, and ultrasonically dispersed for 1 hour to obtain a graphene dispersion. The content of graphene in toluene after modified by aniline tetramer reached 1g / L.

[0045] Add the graphene dispersion to 46g epoxy resin ((model is E44, purchased from Jiangsu Wujiang Heli Resin Factory), mix to obtain mixture A. Then add 1g leveling agent, 1g Defoamer, 1g anti-settling agent and 46g polyamide curing agent are stirred evenly to obtain the graphene composite coating.

[0046] The obtained graphene composite coating is coated on a carbon steel substrate, and after the toluene volatilizes, the graphene composite coating is obtained.

[0047] In order to compare the experimental effects, the epoxy resin coating of Comparative Example 1 was also prepared. The preparation method of the epoxy resin coating described in Comparative Example 1 is the same as in Example 2, except that no graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com