Multifunctional overflow valve for teaching and practical training and operation method

A multi-functional, relief valve technology, applied in the field of hydraulic valves, to achieve the effect of high use value, compact structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

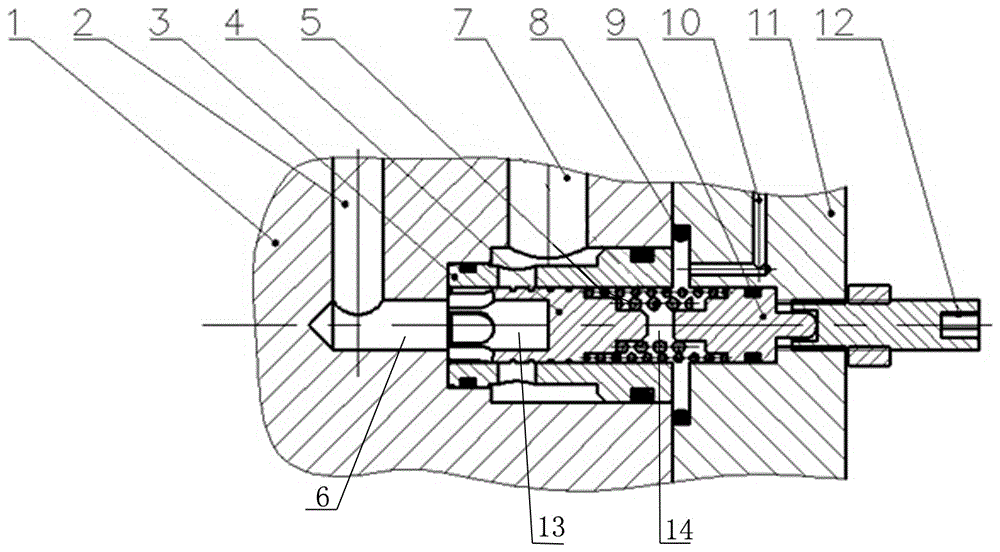

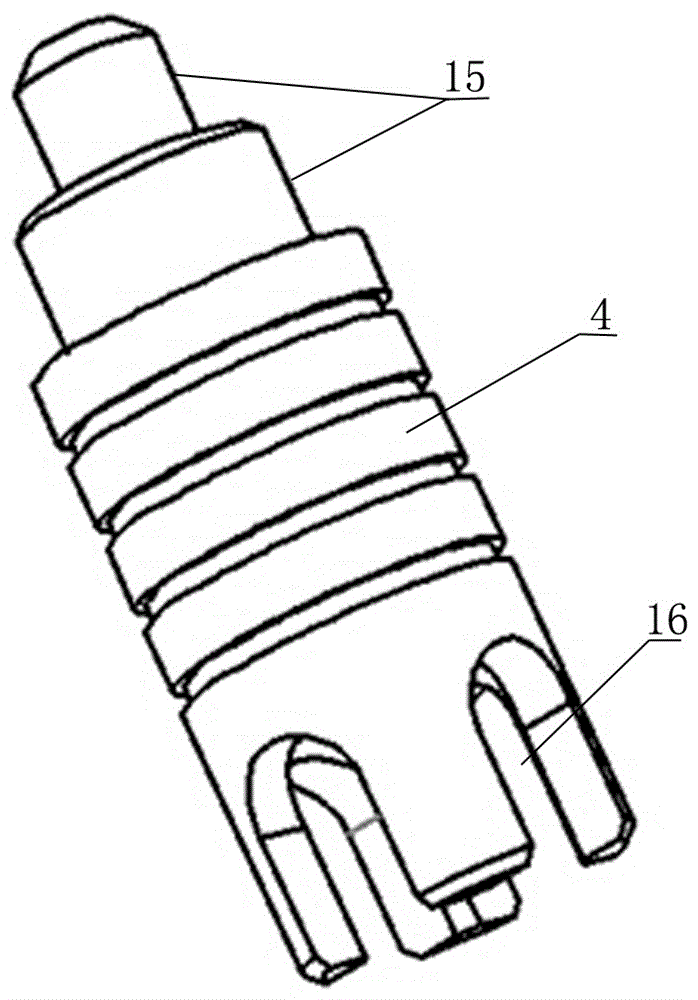

[0022] Such as figure 1 As shown, a multifunctional overflow valve for teaching and training includes a valve body 1 with a valve cavity, a valve sleeve 3 installed in the valve cavity, a valve core 4 slidingly arranged in the valve sleeve 3, and a valve sleeve 3 The valve cavity is divided into left cavity 6, middle cavity 13 and right cavity 14 with the spool 4. The valve body 1 is provided with a high-pressure oil inlet 2, a zero-pressure oil return port 7, a control oil port 10, and a high-pressure oil inlet 2. , zero-pressure oil return port 7 and control oil port 10 communicate with the left cavity 6, the middle cavity 13, and the right cavity 14 respectively through oil channels; one end of the spool 4 is provided with a spring guide seat 9, the spool 4 and the spring guide seat There are two springs 5 with different rigidities between the 9, and the two ends of the spring 5 are respectively pressed on the valve core 4 and the spring guide seat 9; the other end of the...

Embodiment 2

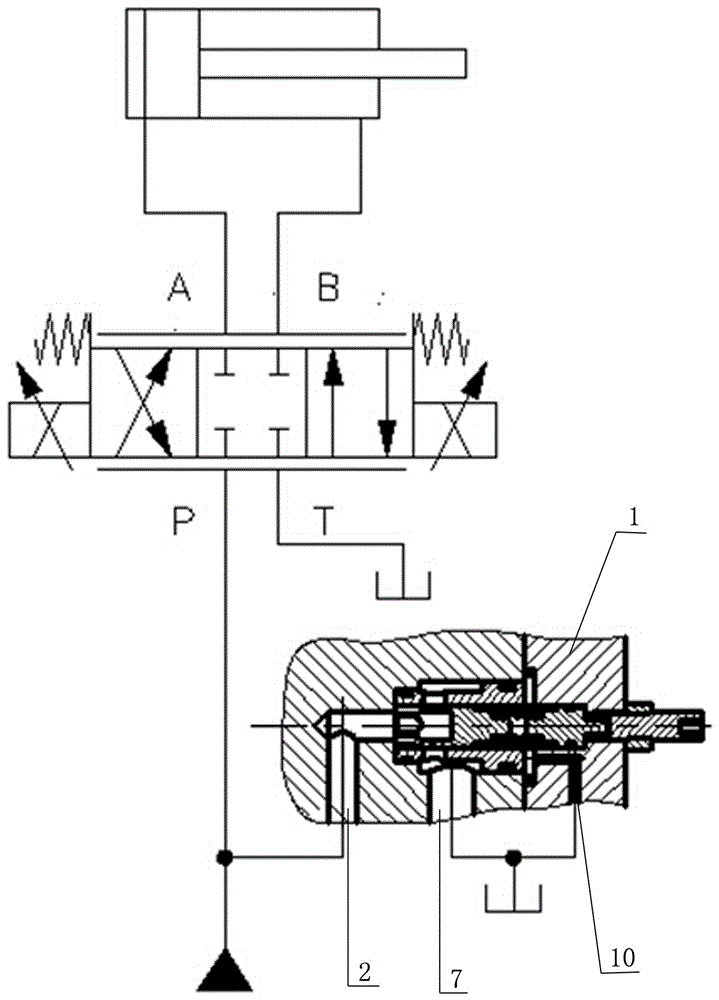

[0027] This embodiment discloses an operation method of a multifunctional overflow valve for teaching and training. At this time, the overflow valve is used as a traditional overflow valve, such as image 3 As shown, the high-pressure oil inlet 2 is connected to the pressure oil outlet, and the zero-pressure oil return port 7 and the control oil port 10 are connected to the oil tank. The pressure oil enters the valve body 1 from the high-pressure oil inlet 2 and acts on the valve core 4. When the pressure When it is greater than the set value of the spring force, the spool 4 slides to the right, and the pressure oil is discharged into the oil return tank from the zero pressure oil return port 7, and the system pressure is changed by adjusting the adjusting screw 12. At this time, the multifunctional overflow valve for teaching and training is used as a traditional overflow valve, but a larger system pressure can be obtained by adjusting the adjusting screw 12, which can be used...

Embodiment 3

[0030] This embodiment discloses another operation method of the multifunctional overflow valve for teaching and training. At this time, the overflow valve is used as a differential overflow valve, such as Figure 4 As shown, the high-pressure oil inlet 2 is connected to the pressure oil outlet, the zero-pressure oil return port 7 is connected to the mailbox, and the control oil port 10 is connected to the highest load pressure detection port of the system. The pressure oil enters the valve body from the high-pressure oil inlet 2 and acts on the valve body. At the left end of spool 4, the highest load pressure of the system and the spring force act on the right section of spool 4 together. After stabilization, a force balance is established on spool 4, namely F 左 =F 右 +F 弹 , F 左 The force generated by the system supply pressure at the left end of the spool 4, F 右 is the force generated at the right end of spool 4 by the highest load pressure of the system, F 弹 It is the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com