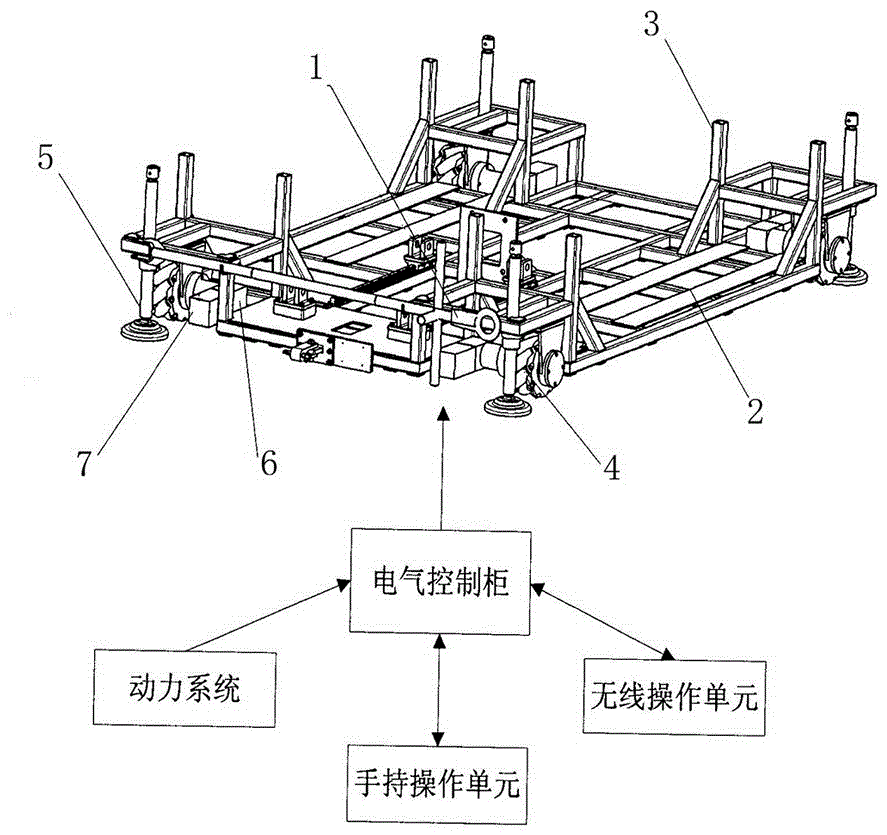

Adjusting device for chassis self-walking mechanism for aircraft engine installation and debugging method of adjusting device

An aircraft engine and debugging method technology, which is applied in the direction of motor vehicles, aircraft parts, ground devices, etc., can solve the problems of inability to achieve precise positioning, low degree of automation, difficult direction control, etc., to improve the degree of automation and reliability, Simple operation and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The debugging method of the self-propelled mechanism adjustment device of the chassis of the aircraft engine installation vehicle, the steps are:

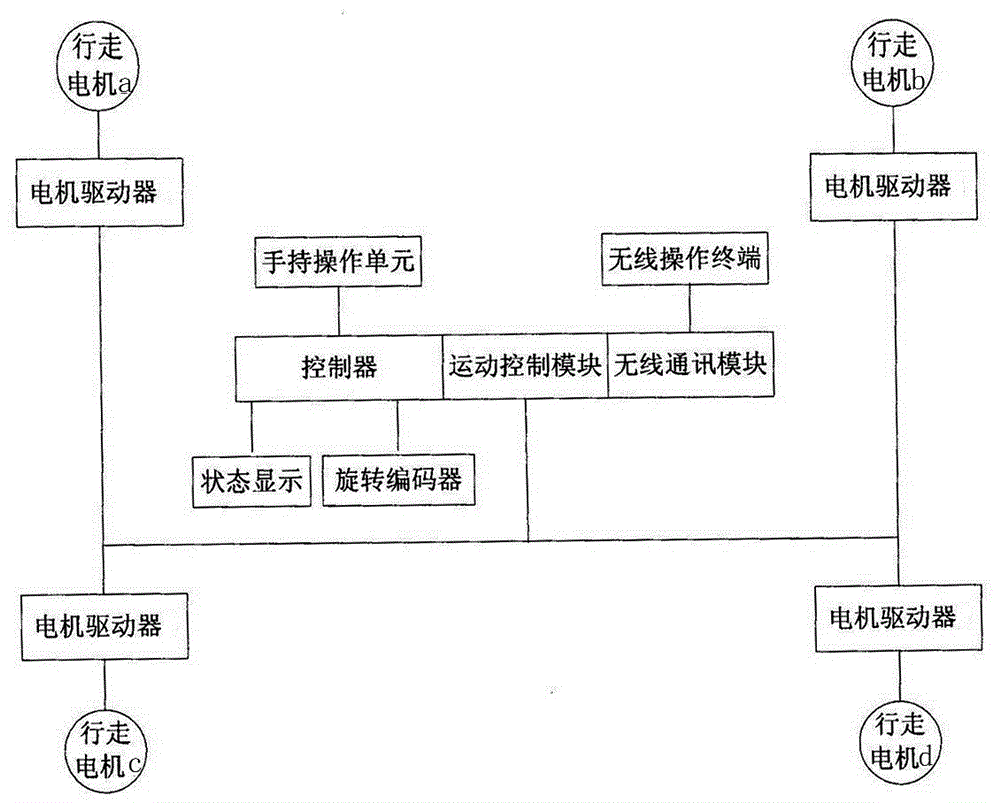

[0020] 1) Use the hand-held operating unit or wireless communication unit to input information into the controller to select the gear speed of the walking chassis mechanism, which are low speed, medium speed or high speed mode;

[0021] 2) Determine the direction of movement of the walking chassis according to specific needs, specifically "front", "rear", "left", "right", "front left", "rear left", "front right", "rear right", " Rotate left" or "rotate right", and transmit the direction of motion to the controller;

[0022] 3) The controller performs specific analysis and processing on the received direction information:

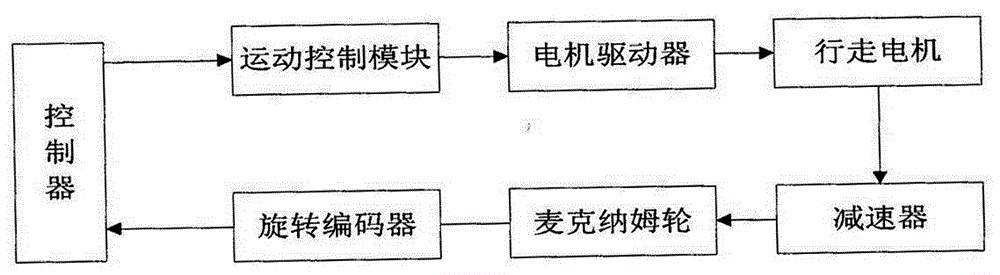

[0023] 3a), transmit the parameters to the motor driver through the motion control module, and drive the four motors to drive the four mecanum wheels respectively, and the speeds of the four mecanum wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com