A method for analyzing natural frequency characteristics of turbomachinery blades based on cpu+gpu heterogeneous parallel computing

A turbomachinery, natural frequency technology, applied in the direction of calculation, geometric CAD, design optimization/simulation, etc., can solve problems such as uncomfortable calculation amount and complicated operation, and achieve the effect of reducing calculation time and improving calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

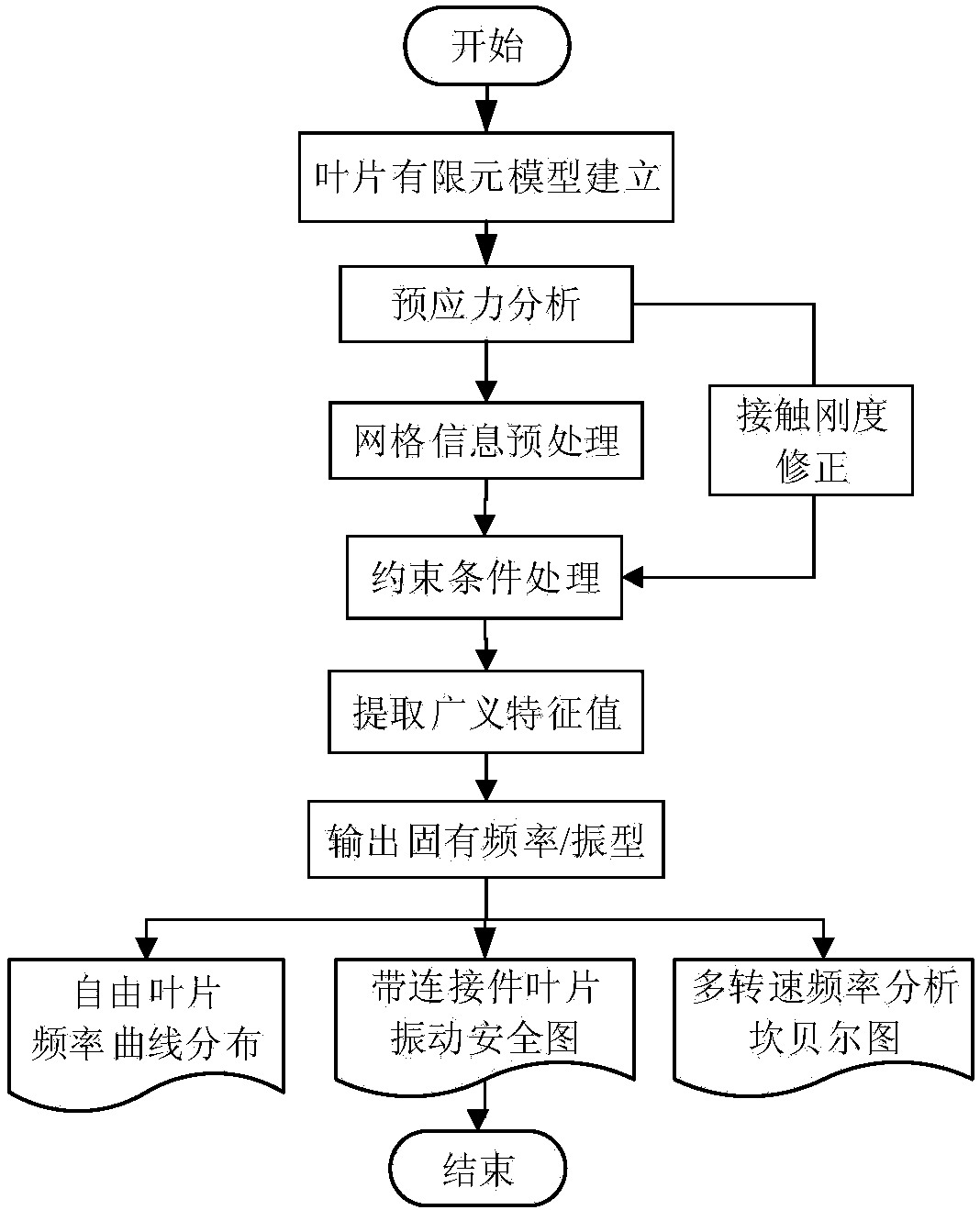

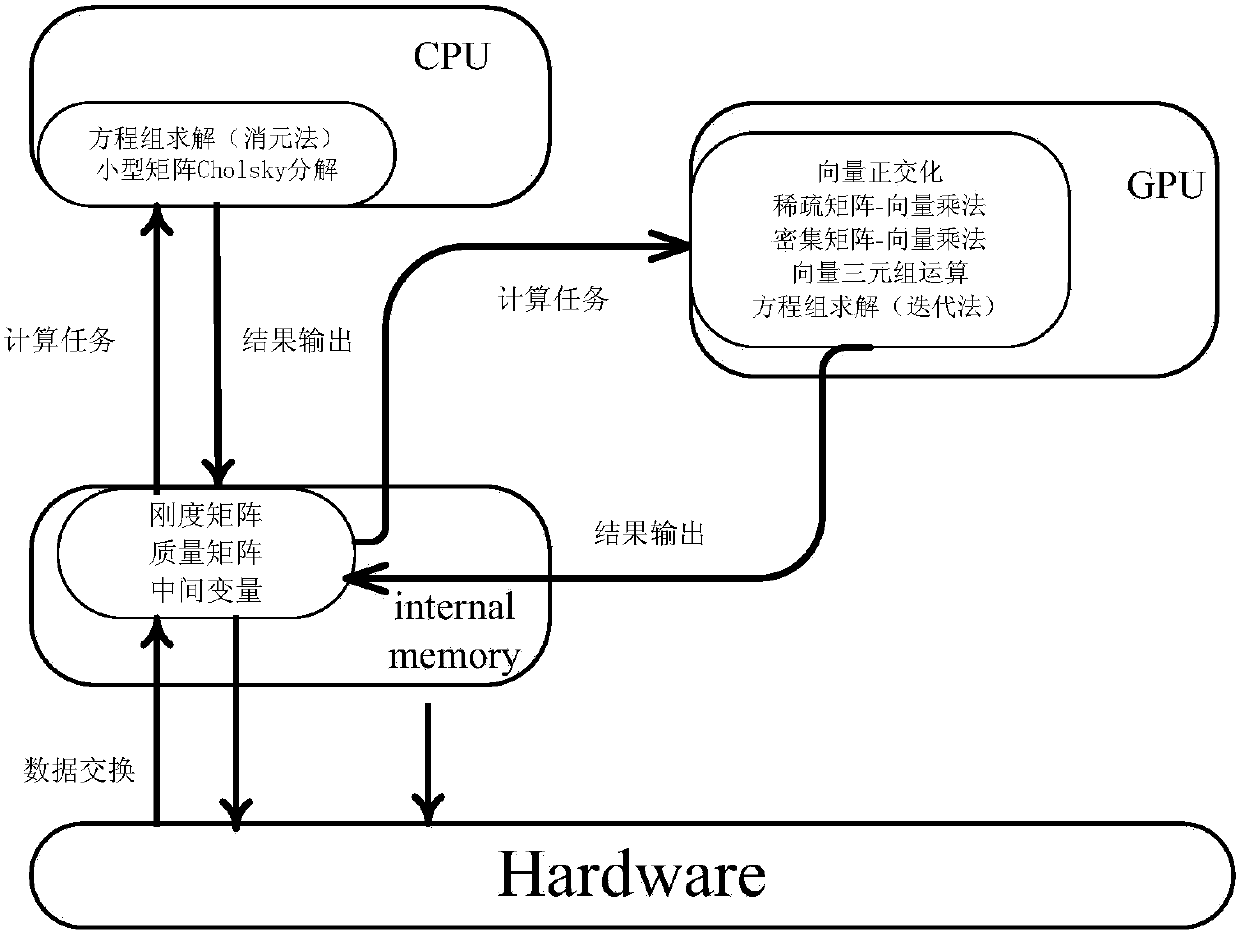

Method used

Image

Examples

example 1

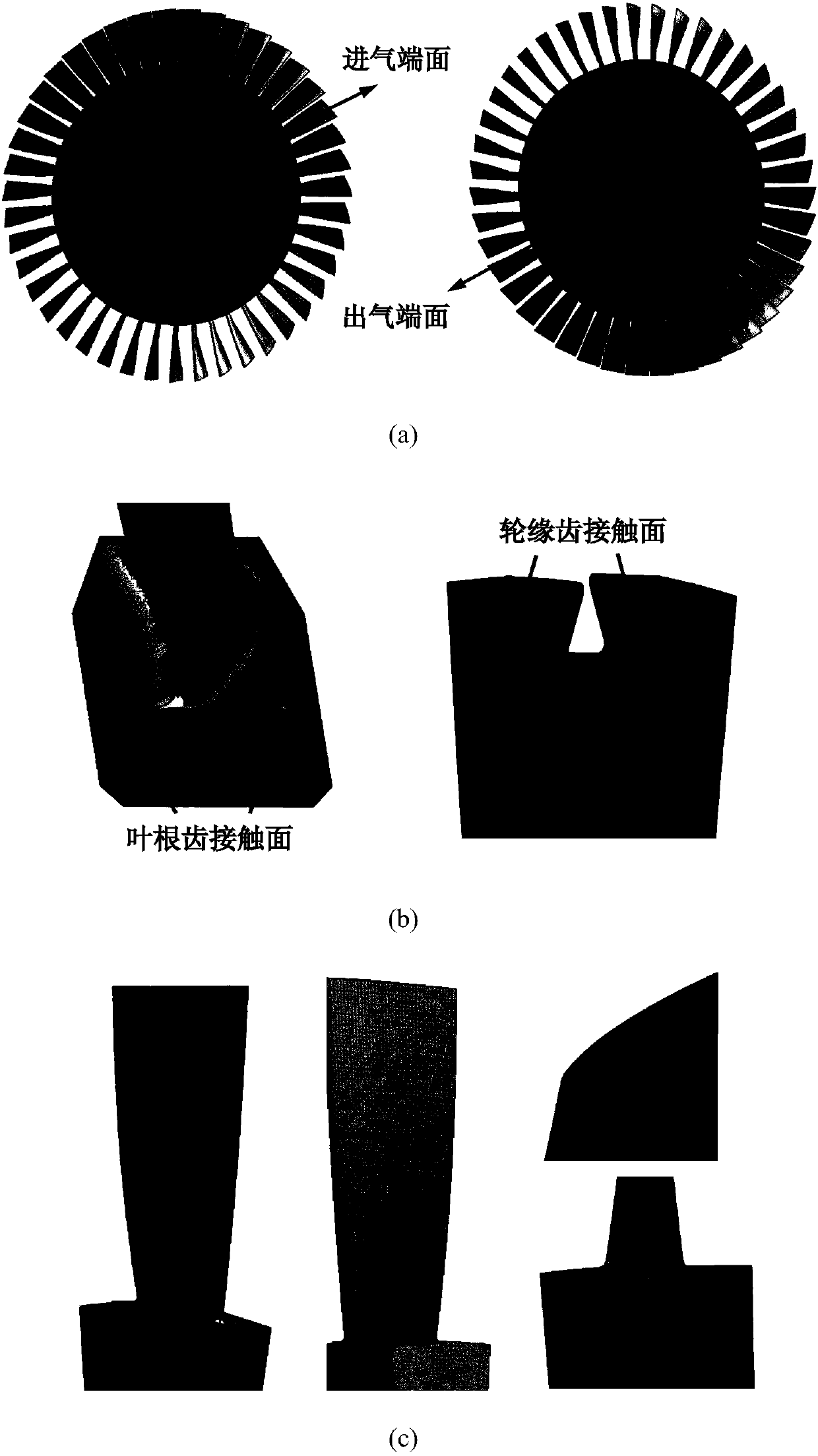

[0104] Example 1 Take a whole circle of free blades (without connectors) as an example. The three-dimensional model has a dovetail-shaped blade root and a rim, with a total of 43 blades. image 3 In (a) the geometric model of the entire blade is given, and (b) is a schematic diagram of the dovetail-shaped blade root-rim contact surface. The material parameters of the blade and the rim are shown in Table 1. Mesh generation is done in ANSA software, image 3 In (c) the local finite element mesh model, the main body of the mesh adopts 8-node hexahedral elements, and the transition part of the blade root uses tetrahedron and degenerate elements for meshing. The whole has a total of 760,885 elements and 728,400 nodes.

[0105] Table 1 Material properties of a free blade and rim

[0106]

[0107] A centrifugal load with a working speed of 3000r / min is applied to the blade for prestress analysis; the cell matrix is calculated on the CPU (Intel Xeon E5-2650) and GPU (Nvidia Tesl...

example 2

[0112] Example 2 Taking a whole circle of blades with connectors (shroud and damping block) as an example, the 3D model uses fungal leaf roots, and the whole circle of blades is connected through the contact of the damping block and the shroud, a total of 92 blades , Figure 6 (a) shows the geometric model of the entire circle of the blade, (b) is a schematic diagram of the connecting parts (shroud and damping block), and the material parameters of the blade and the rim are shown in Table 3. Mesh generation is done in ANSA software, Figure 6 (c) is the local finite element mesh model of the blade. The main body adopts 8-node hexahedral elements, and the transition part between the blade root and the shroud adopts tetrahedron and degenerate elements for meshing. The total number of nodes in the overall model is 1176877. The total number of units is 1,337,312.

[0113] Table 3 Material properties of a blade and rim with connectors

[0114]

[0115] A centrifugal load with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com