A dry-type transformer bushing end screen lead-out device

A dry-type transformer and lead-out technology, which is applied to transformer/inductor parts, transformer/inductor coils/windings/connections, electrical components, etc., to achieve the effect of improving production and testing efficiency, simple process, and simplified parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

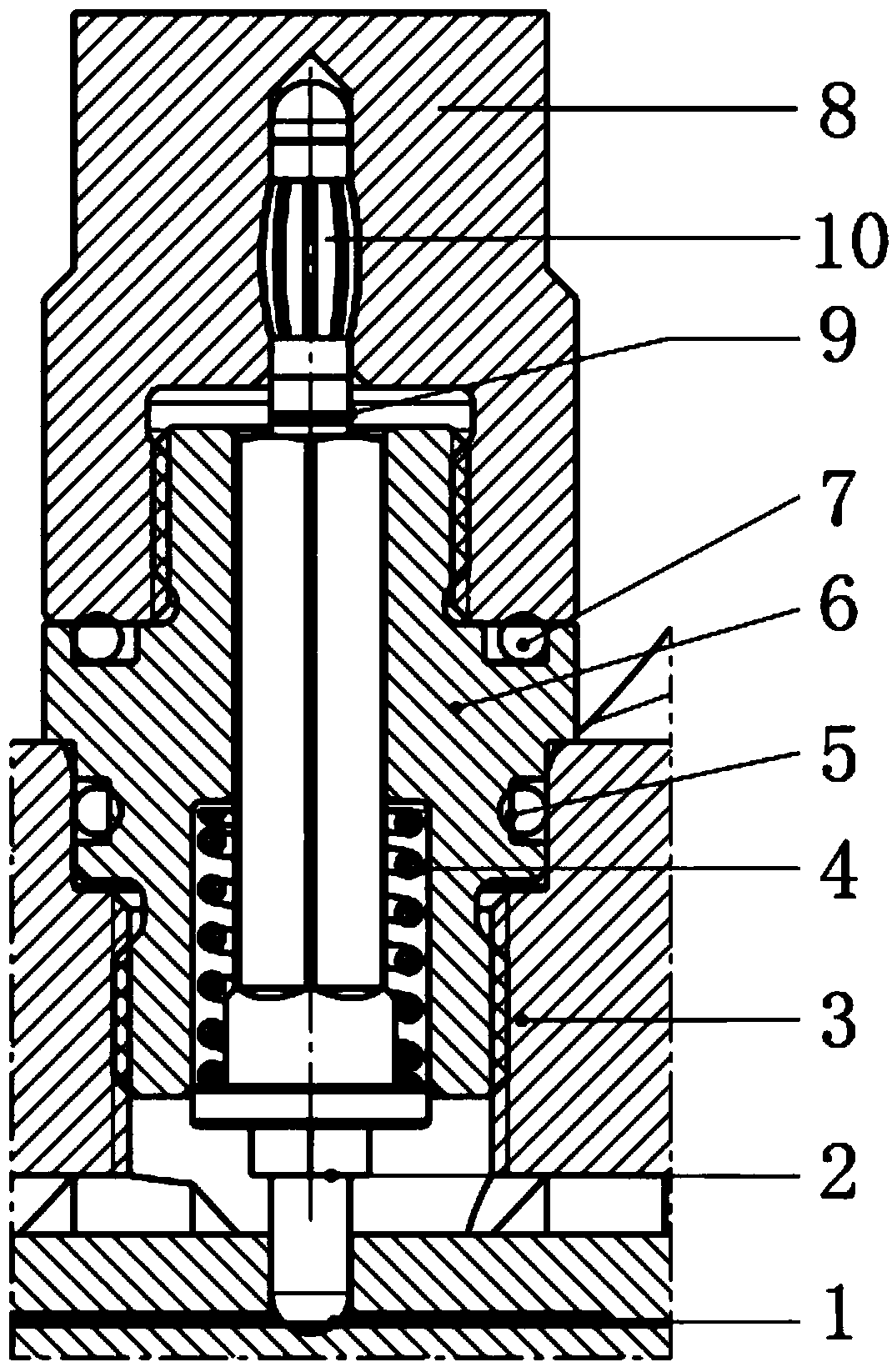

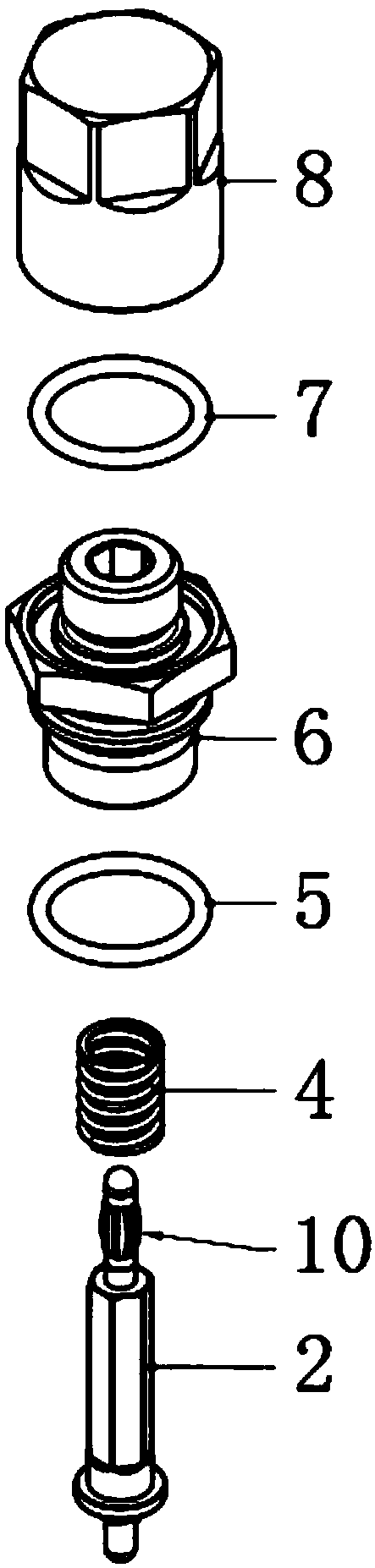

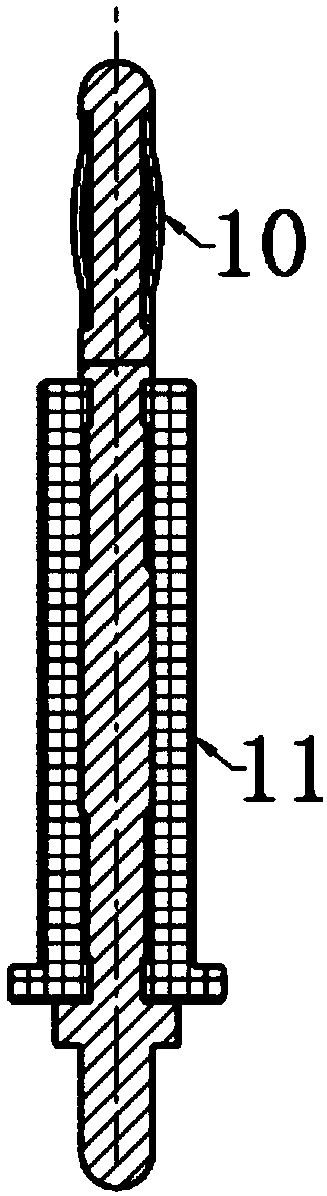

[0026] Such as figure 1 , figure 2 As shown, the lead-out device for the end screen of the dry-type transformer bushing of the present invention includes the end screen 1, the end screen connection plug 2, the bushing installation flange 3, the grounding compression spring 4, the first sealing ring 5, and the tap mounting seat 6 , the second sealing ring 7, the tap grounding protector 8.

[0027] Between the insulating layer of the last screen 1 and the bushing installation flange 3 of the present invention, a through hole coaxial with the inner threaded hole of the last screen installation provided on the bushing installation flange 3 is drilled in advance, and the inner diameter of the hole is slightly larger than that of the last screen connection The outer diameter of the lower end of the plug 2 is to improve the shock resistance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com