Positive electrode, and battery containing same

A positive electrode, battery technology, applied to the positive electrode. It can solve the problems of limiting the battery and the deterioration of the electrochemical performance of the battery, and achieve the effects of improving the floating charge life, good battery performance consistency, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of the positive electrode sheet is not particularly limited. In a specific embodiment, the slurry containing the positive electrode active material is first prepared, and then the slurry is formed on the second carrier, and the positive electrode active material is formed on the second carrier by drawing the slurry.

[0085] The second carrier mainly plays the role of carrying the positive electrode active material, and the second carrier itself is electrochemically inert. According to those skilled in the art, electrochemical inertness means that the second carrier does not participate in any electrochemical reaction and exists stably in the positive electrode sheet. It exists as a matrix that supports the active material layer.

[0086] In a specific embodiment, the second carrier is electronically insulated and has a porous structure. Specifically, the pore size of the second carrier ranges from 50 mesh to 200 mesh. In this way, on the premise o...

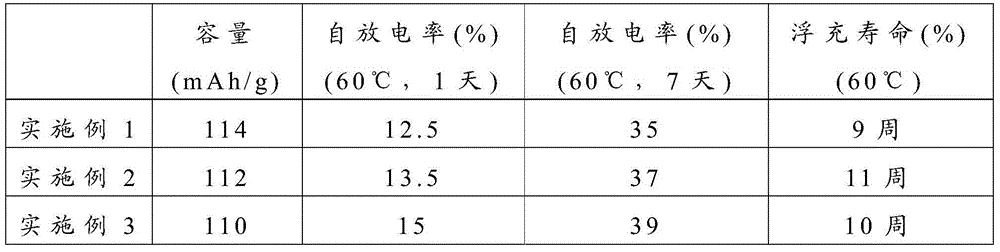

Embodiment 1

[0144] Preparation of positive electrode: Lithium manganate LMO, conductive agent graphite KS15, binder styrene-butadiene rubber (SBR) and sodium carboxymethyl cellulose (CMC) according to the mass ratio LMO:CMC:SBR:graphite=86.5:1:2.5: 10 mixed in water to form a homogeneous cathode slurry. Fully immerse the nylon mesh in the positive electrode slurry, then pull the nylon mesh with the positive electrode slurry out of the positive electrode slurry tank, and scrape off the excess slurry on the positive electrode collector according to the predetermined thickness with a scraper, so as to realize the control of the positive electrode collector. The thickness of the positive electrode slurry on the fluid, and make the slurry on the surface of the positive electrode current collector more uniform. Dry the positive electrode current collector with the positive electrode slurry at 60°C to form an active material layer, and then press it into a sheet and cut it into a size of 8×10cm ...

Embodiment 2

[0152] In embodiment 2, lithium manganate LMO, conductive agent graphite KS15, binder styrene-butadiene rubber (SBR) and sodium carboxymethyl cellulose (CMC) are according to mass ratio LMO:CMC:SBR:graphite=84.5:1 :2.5:12 Mix in water to form a uniform positive electrode slurry. The rest of the composition and preparation method of the positive electrode sheet are the same as in Example 1.

[0153] The rest of the composition and preparation method of the battery are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com