How to improve the high temperature float charge life of agm valve-regulated sealed battery

A technology of floating charge life and battery, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve the problems of increasing the difficulty of reaching the standard, and achieve the effects of reducing gas emissions, inhibiting oxidation, and reducing void volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Example 1: Select a liquid absorption capacity of 8.6g / g, a maximum pore size of 17.0μm, and a specific surface area of 1.6m 2 / g separators are grouped; the pole group is pretreated: SiO 2 The solution with a content of 0.25% is evenly sprayed on one surface of the separator, and the mass of the separator increases by 1.0% after spraying, and the assembly and welding are carried out according to the conventional process; the sulfuric acid content is 5.14g / Ah and the water content is After adding 8.54g / Ah of electrolyte, the formation charging is carried out according to the conventional production process.

example 2

[0014] Example 2: Select a liquid absorption capacity of 8.8g / g, a maximum pore size of 16.5μm, and a specific surface area of 1.8m 2 / g separators are grouped; the pole group is pretreated: SiO 2 The solution with a content of 0.35% is evenly sprayed on one surface of the separator, and the quality of the separator is increased by 0.5% after spraying, and the assembly and welding are carried out according to the conventional process; the sulfuric acid content is 5.18g / Ah and the water content is After adding 8.26g / Ah of electrolyte, the formation charging is carried out according to the conventional production process.

example 3

[0015] Example 3: Select a liquid absorption capacity of 8.7g / g, a maximum pore size of 17.5μm, and a specific surface area of 2.0m 2 / g separators are grouped; the pole group is pretreated: SiO 2 The solution with a content of 0.30% is evenly sprayed on one surface of the separator, and the mass of the separator increases by 0.8% after spraying, and the assembly and welding are carried out according to the conventional process; the sulfuric acid content is 5.16g / Ah and the water content is After adding 8.81g / Ah of electrolyte, the formation charging is carried out according to the conventional production process.

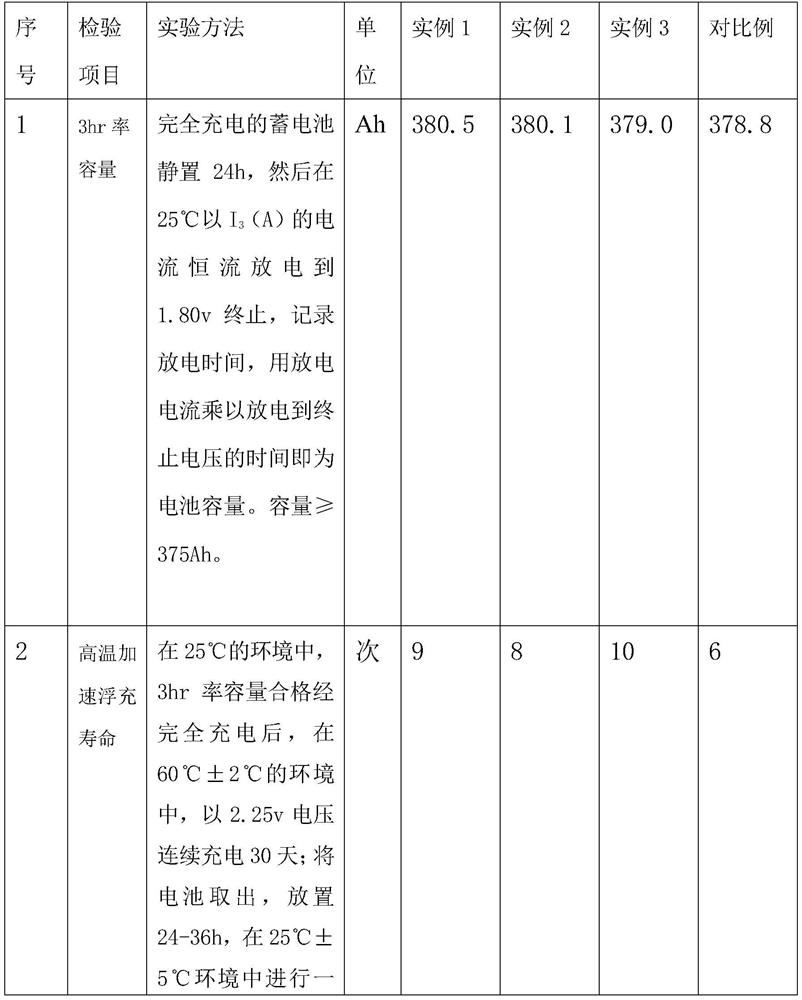

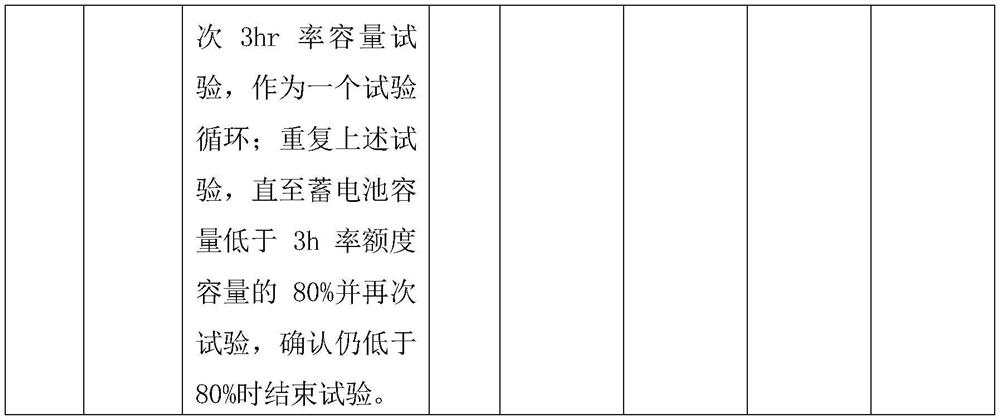

[0016] The following table is the comparison data of the cycle life of the 2V valve-regulated sealed lead-acid battery produced according to the above-mentioned embodiment and the 2V2V valve-regulated sealed lead-acid battery produced according to the existing technology (comparative example) under high temperature accelerated floating charge (taking 2V 500Ah bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com