Inserted type connector

A connector and receptacle technology, which is applied in the direction of connection, parts of connecting devices, devices for connecting/disconnecting connecting parts, etc., can solve the problems of high mold forming accuracy, poor locking firmness, and high processing costs , to achieve good locking effect, better locking performance and improved firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

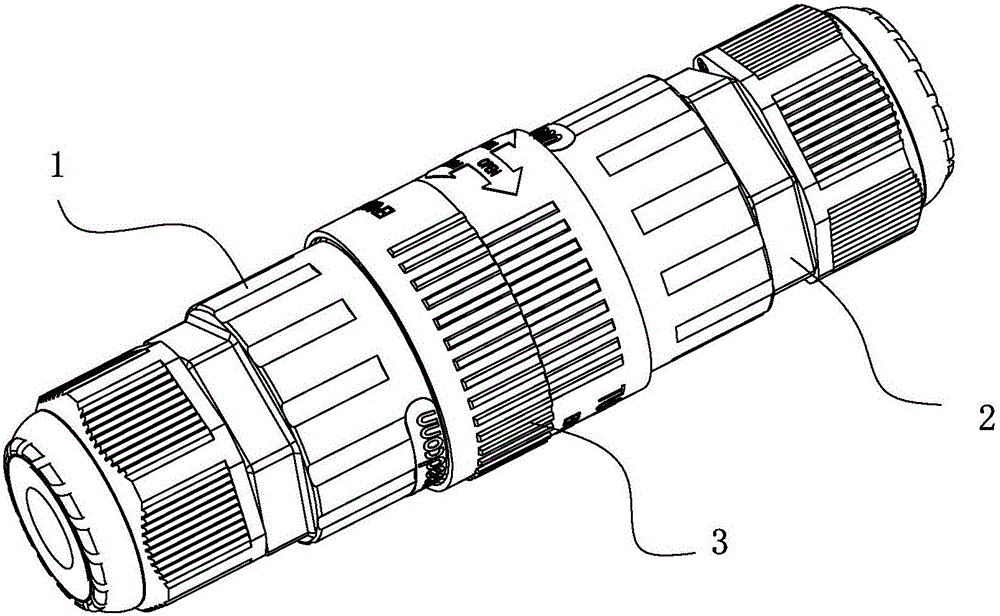

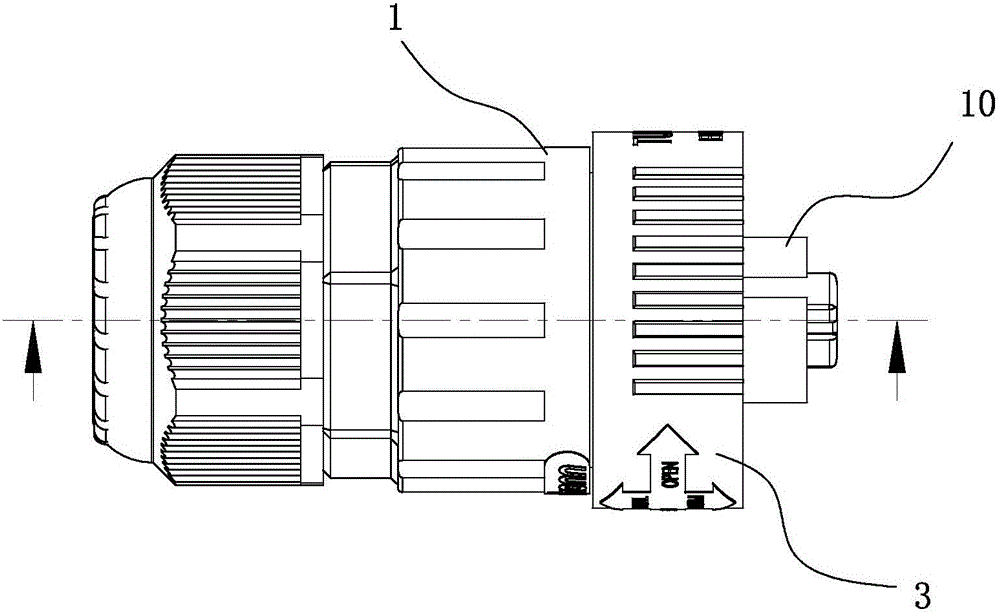

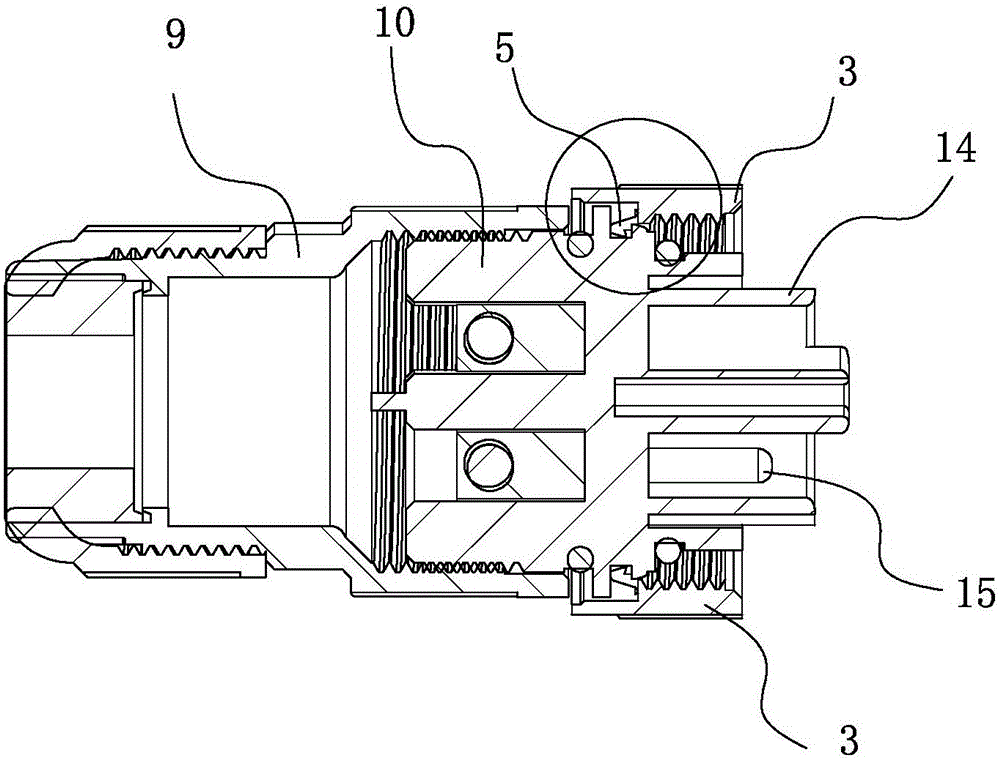

[0028] Embodiment one: see Figure 1-8 As shown, a plug-in connector includes a male end 1 and a female end 2, and a locking structure 3 set between the male end 1 and the female end 2, the locking structure 3 is in the form of a ring There are several anti-slip protrusions 4 on the outer edge surface, and a radial limit structure 5 is provided on the end surface of the inner ring wall close to one side, extending from the radial limit structure 5 to the other end surface of the inner ring wall There is a threaded structure 6 on it; the outer edge surface of the male end 1 is provided with a limit groove 7 that cooperates with the radial limit structure 5, and the outer edge surface of the female end 2 on the other side An external thread 8 engaged with the threaded structure 6 is provided on it.

[0029] Such as figure 2 , 3 As shown, the male end 1 and the female end 2 respectively include a housing 9 and a rubber core 10, the housing 9 and the rubber core 10 are screwed...

Embodiment 2

[0034] Embodiment 2: A pair of plug-in connectors, including a male end and a female end, and a locking structure set between the male end and the female end. The locking structure is ring-shaped, and the outer edge surface There are several anti-slip protrusions on the top, and a radial limit structure is provided on the end surface of the inner ring wall close to one side, and a thread structure is provided on the end surface of the other side of the inner ring wall from the radial limit structure; A limiting groove cooperating with the radial limiting structure is provided on the outer peripheral surface of the female end, and an external thread engaged with the threaded structure is provided on the outer peripheral surface of the male end on the other side.

[0035] In this embodiment, the radial limiting structure is a protruding ring arranged along the inner ring wall of the locking structure. When the protruding ring falls into the limiting groove of the female end, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com