Natural acidification of frozen dairy desserts using natural plant sources

A natural, acidulant technology, applied in frozen desserts, applications, food science, etc., can solve the problems of limited use of organic acids, scaling of high-viscosity heat exchangers, and limited dosage, to achieve fine and smooth texture, improve quality. effects on texture and sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

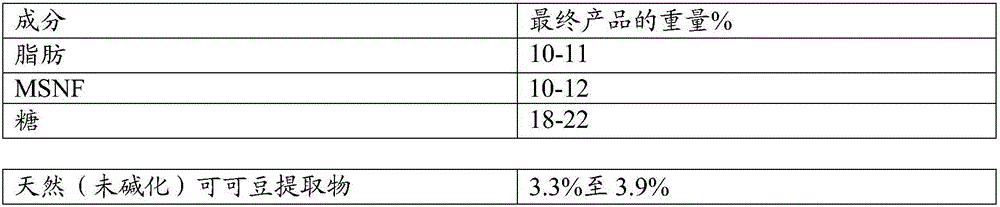

[0123] Example 1: A frozen milk with natural (non-alkalized) cocoa bean extract as acidulant Dessert

[0124]

[0125] A frozen dairy dessert was prepared by mixing the above ingredients and then adding 3.3% to 3.9% by weight of natural (non-alkalized) cocoa extract in powder form to lower the pH to 5.8-6.0. No other acidulants were added to the mixture. The acidified ingredient mixture was then homogenized at 1500 psi in stage one and 500 psi in stage two, followed by pasteurization at 82°C for 90 seconds. The pasteurized mixture is then frozen using a combination of standard continuous industrial freezers or cryogenic freezing.

Embodiment 2

[0126] Example 2: A Frozen Dairy Dessert Containing Alkalized Cocoa Bean Extract

[0127]

[0128] A frozen dairy dessert was prepared by mixing the above ingredients and then adding 3.6% by weight of alkalized cocoa bean extract with 0.1% citric acid to lower the pH. The acidified ingredient mixture was then homogenized in stage one at 1500 psi and in stage two at 500 psi, followed by pasteurization at 82°C for 90 seconds. The pasteurized mixture is then frozen using a combination of conventional freezers and cryogenic freezing.

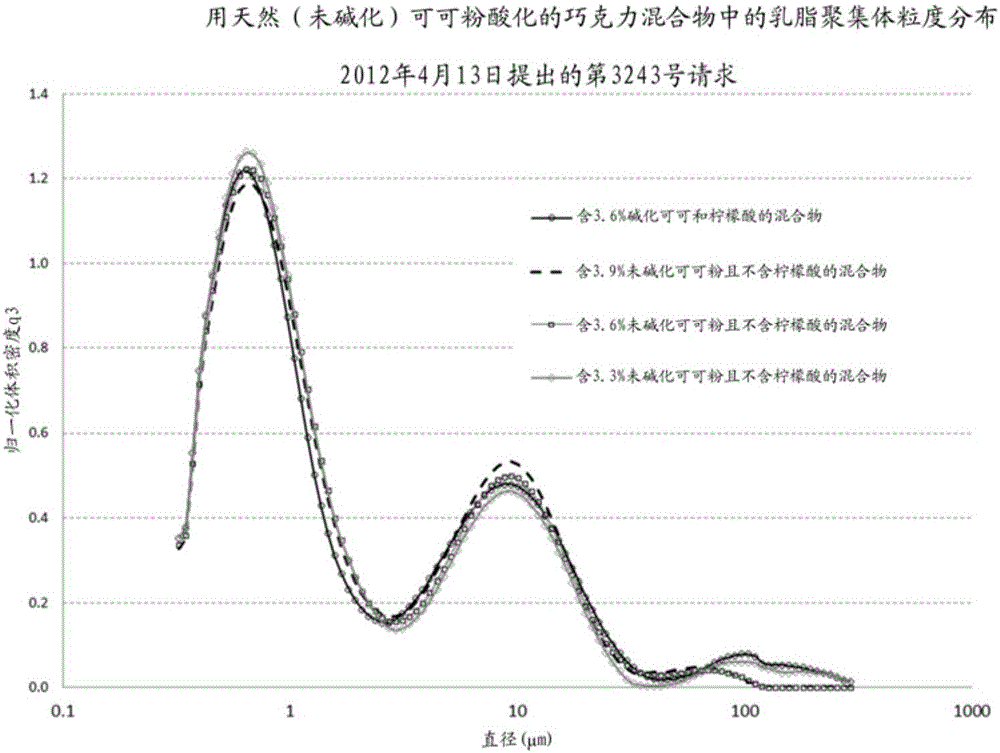

[0129] Volume-based particle size distribution and volume mean diameter

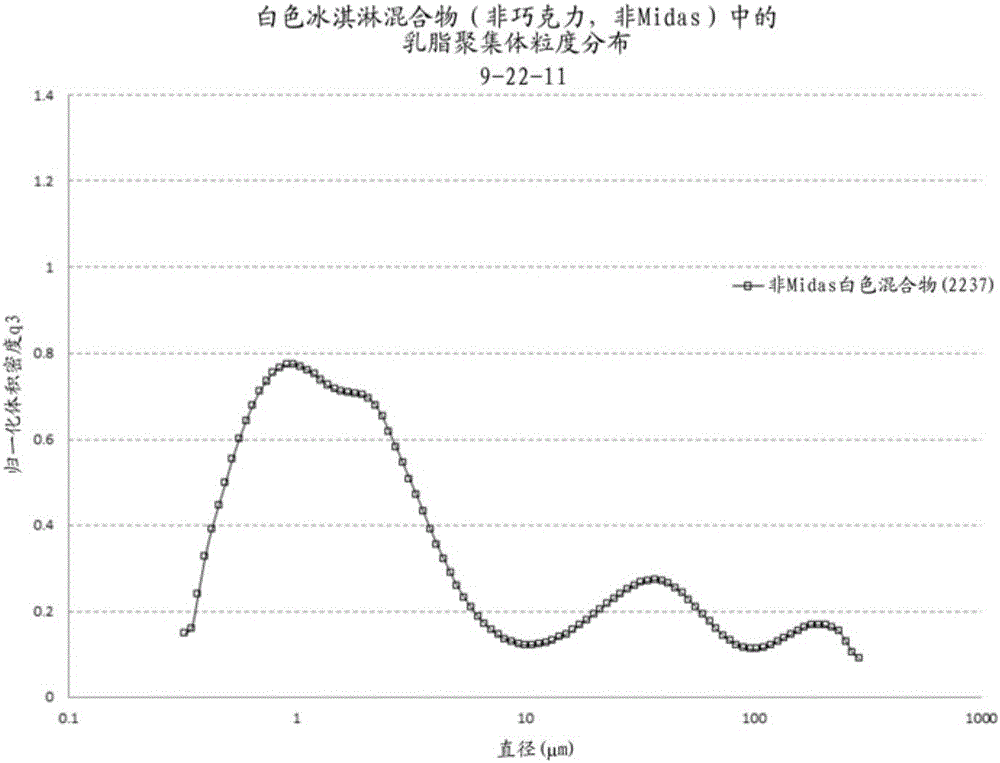

[0130] In this study, the frozen confectionery of Examples 1 and 2 were compared to see the effect of industrial acid and natural acid from unalkalized cocoa powder.

[0131] Frozen dairy desserts acidified with natural non-alkalized cocoa bean extract and frozen dairy desserts acidified with non-natural acid and prepared with alkalized cocoa bean extract were also ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com