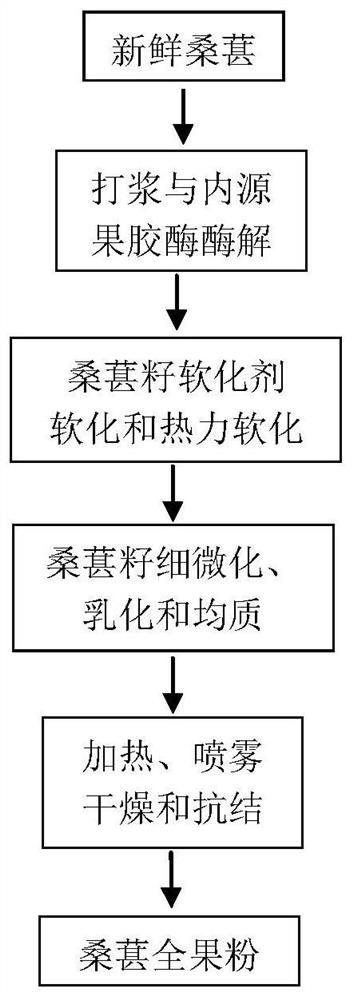

Preparation method of mulberry whole fruit powder

A technology of mulberry and fruit powder, which is applied in the field of food processing to achieve the effects of new and smooth taste, preventing fat ball agglomeration and large powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of mulberry whole fruit powder, the steps are:

[0028] ⑴ Beating and enzymolysis with endogenous pectinase: Take fresh white mulberries harvested within one day, remove the sundries, wash with tap water, drain, and remove the stalks to obtain clean mulberries; take 20 kg of clean mulberries and put them into a stainless steel beater , add 10 kg of pure water with 50% clean mulberry quality, beat for 10 minutes to get mulberry slurry; transfer the mulberry slurry to the enzymatic hydrolysis tank, and under the condition of stirring, control the temperature of the mulberry slurry at 45°C and keep it warm for 3 Hours, the endogenous pectinase released after the destruction of the mulberry's own tissue structure is used to hydrolyze the pectin in the mulberry pulp and the pectin in the mulberry seed skin, destroying the cell wall structure to promote the release and dissolution of the inherent nutrition and health components in the mulberry , 30 kg of ...

Embodiment 2

[0034] A preparation method of mulberry whole fruit powder, the steps are:

[0035] ⑴ Beating and endogenous pectinase enzymolysis: take the fresh red mulberry harvested on the day, remove the sundries, wash with tap water, drain, and remove the stalk to obtain clean mulberry; take 35 kg of clean mulberry and put it into a stainless steel beater , add 17.5 kg of pure water with 50% of the clean mulberry quality, and beat for 20 minutes to obtain mulberry slurry; transfer the mulberry slurry into an enzymatic hydrolysis tank, and under the condition of stirring, control the temperature of the mulberry slurry at 40°C and keep it warm for 6 hours , using the endogenous pectinase released after the destruction of the mulberry's own tissue structure to hydrolyze the pectin in the mulberry pulp and the pectin in the mulberry seed skin, and destroy the cell wall structure to promote the release and dissolution of the inherent nutrition and health ingredients in the mulberry. Obtain 5...

Embodiment 3

[0041] A preparation method of mulberry whole fruit powder, the steps are:

[0042] ⑴ Beating and enzymolysis with endogenous pectinase: Take fresh purple-red mulberries harvested within two days, remove the sundries, wash with tap water, drain, and remove the stalks to obtain clean mulberries; take 50 kg of clean mulberries and put them into stainless steel for beating In the machine, add 25 kg of pure water with 50% clean mulberry quality, beating for 10.5 minutes to obtain mulberry slurry; transfer the mulberry slurry to an enzymatic hydrolysis tank, and under the condition of stirring, control the temperature of the mulberry slurry at 40°C and keep warm For 6 hours, the endogenous pectinase released after the destruction of the mulberry's own tissue structure is used to hydrolyze the pectin in the mulberry pulp and the pectin in the mulberry seed skin, destroying the cell wall structure to promote the release and release of the inherent nutrition and health ingredients in m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com