Oil-fried puffed food subjected to secondary fermentation and capable of being continuously produced and preparation method thereof

A technology of secondary fermentation and puffing food, which is applied in food ingredients as taste improver, food science and other directions, can solve the problems of poor crispness, hard taste, damaged dough, etc., and achieves distinctive flavor, good crispness, and prospects expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0022] The invention discloses a fried puffed food which can be continuously produced through secondary fermentation and a production method thereof. Through the production method, a fried puffed food with good crispness, good flavor and high sense of value can be obtained; The reason for its realization mainly lies in that the present invention optimizes the raw material formula of the fried type puffed food and innovates the production method of the fried type puffed food. The details are as follows:

[0023] One, make fried type puffed food of the present invention

[0024] 1. Make fried noodles (semi-finished products)

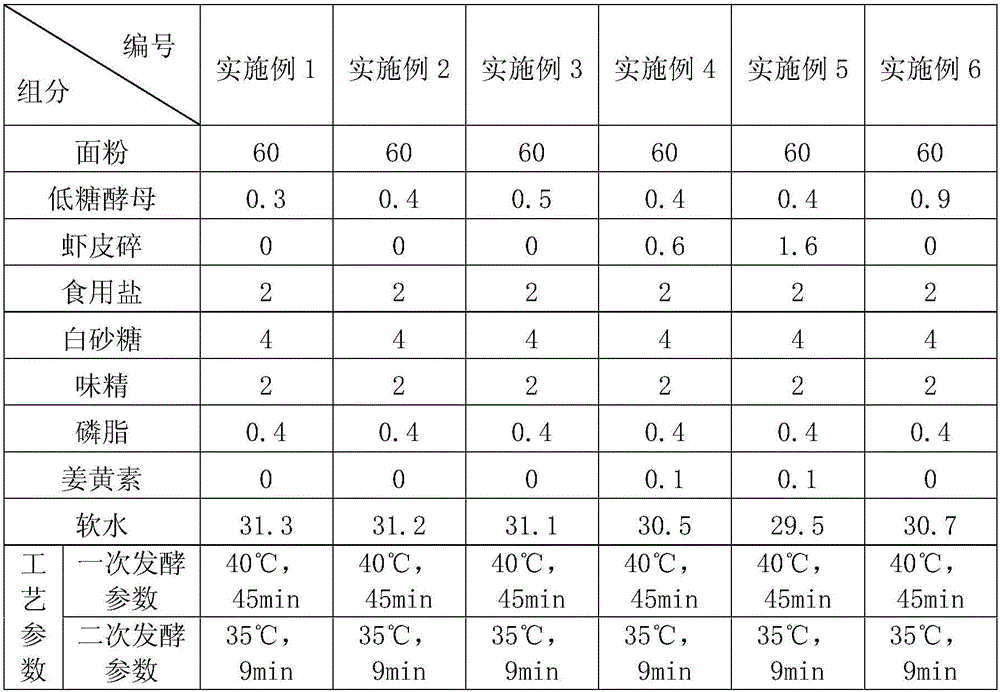

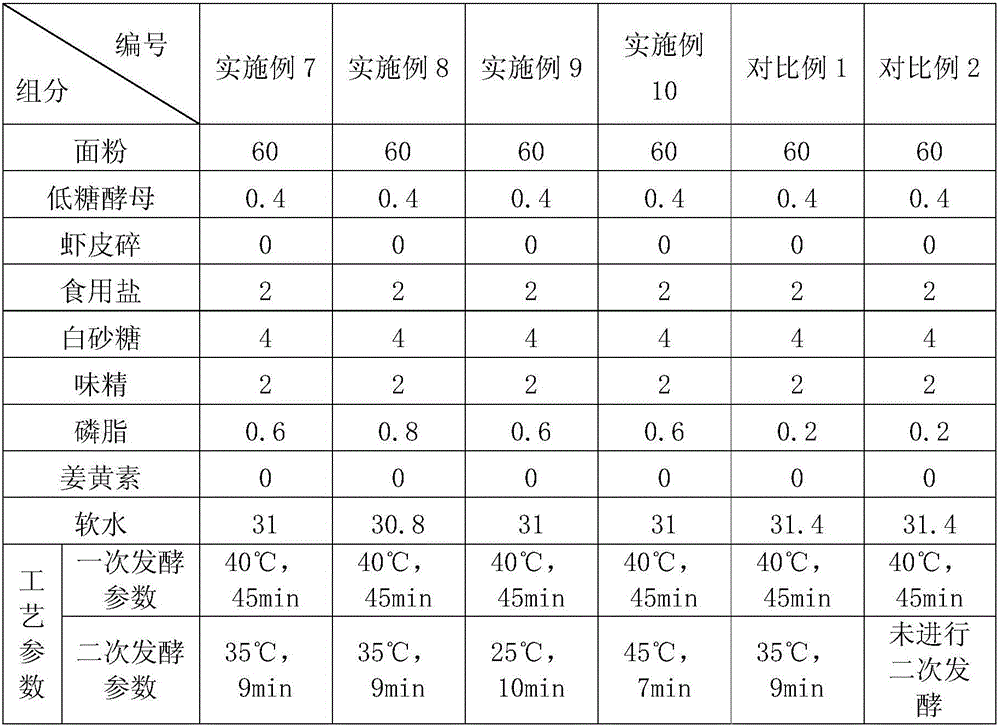

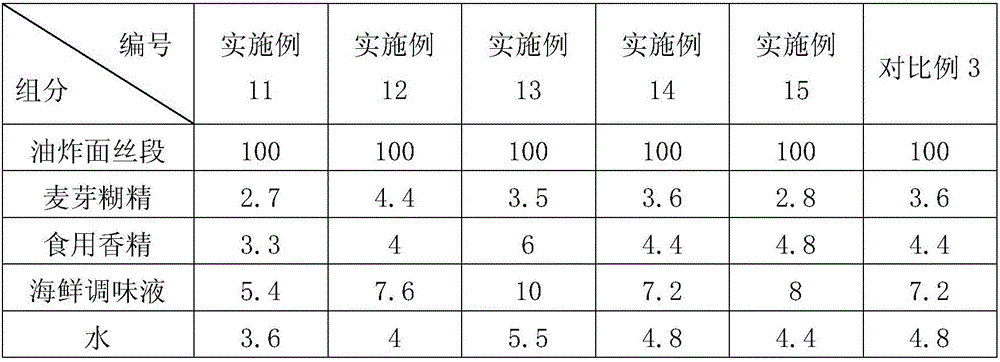

[0025] Embodiments 1-10 and Comparative Examples 1-2 are all based on the weight of the raw materials described in Tables 1-2 and the corresponding process parameters, according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com