Shoe sole with spiral breathable waterproof element

A breathable, waterproof and component technology, applied in soles, footwear, applications, etc., can solve the problems of complex structure, easy to fall off, shift, hot air backflow, etc., to avoid sultry environment, improve the ventilation effect, and the effect of good ventilation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

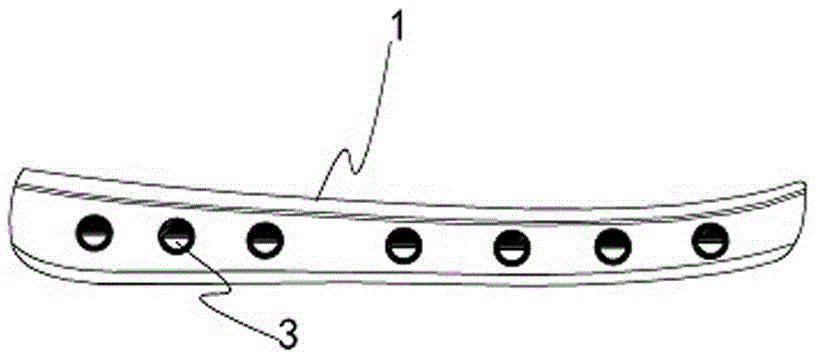

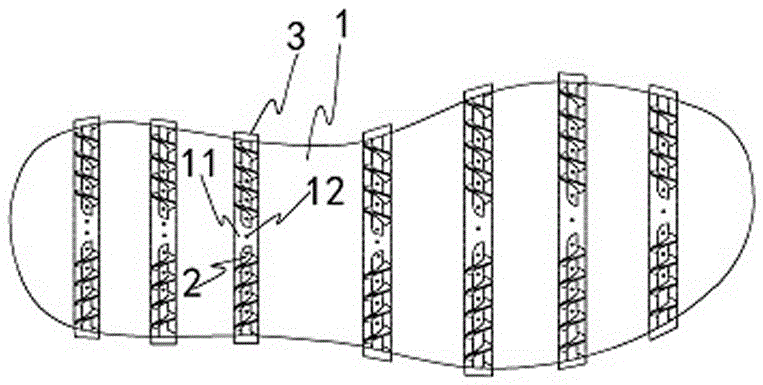

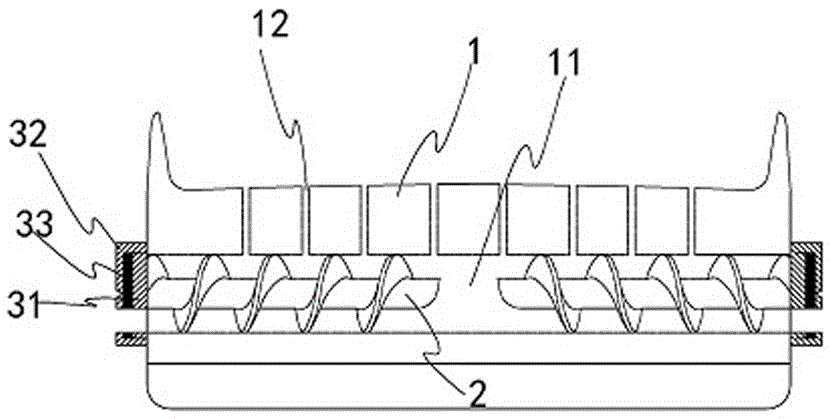

[0018] refer to Figure 1 to Figure 6 , the embodiment of the present invention discloses that a shoe sole provided with a spiral breathable and waterproof element includes a sole body 1 and a spiral breathable and waterproof element, the spiral breathable and waterproof element includes a threaded rod 2 and a cap 3 with threads on the outer surface, The cap 3 includes an inner cap 31 and an outer cap 32, the inner cap 31 is sleeved in the outer cap 32, and a sealing structure 33 is arranged between the inner cap 31 and the outer cap 32, so that The inner cap 31 is provided with a first air vent, and the outer cap 32 is provided with a second vent, and the inner cap 31 and the outer cap 32 can rotate relative to each other to realize the first vent and the second vent. The connection or partition of the two air vents, the outer layer cap 32 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com