Gas particulate matter unpowered purification equipment and gas particulate matter recycling method

A technology for purifying equipment and particulate matter, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of high purification investment cost, high daily maintenance cost, secondary pollution, etc., and achieve good environmental performance and low daily maintenance cost Low, secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

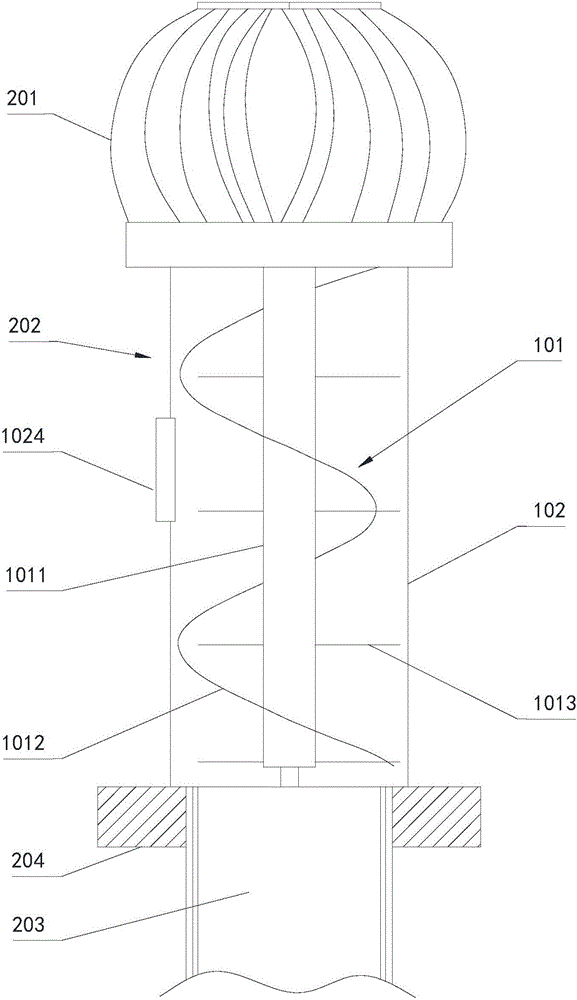

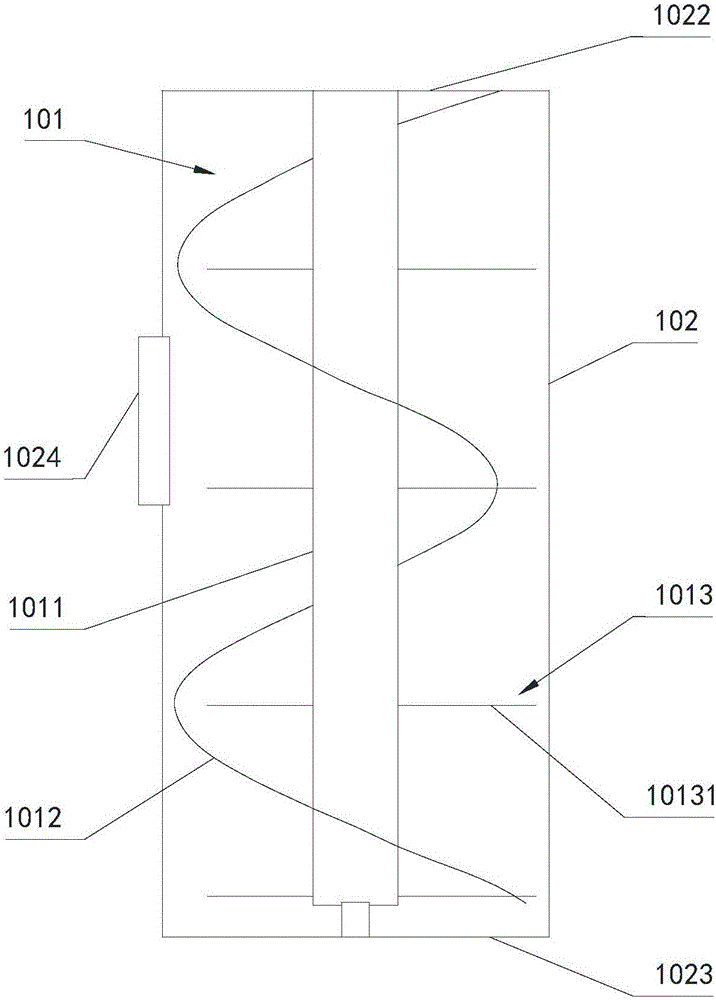

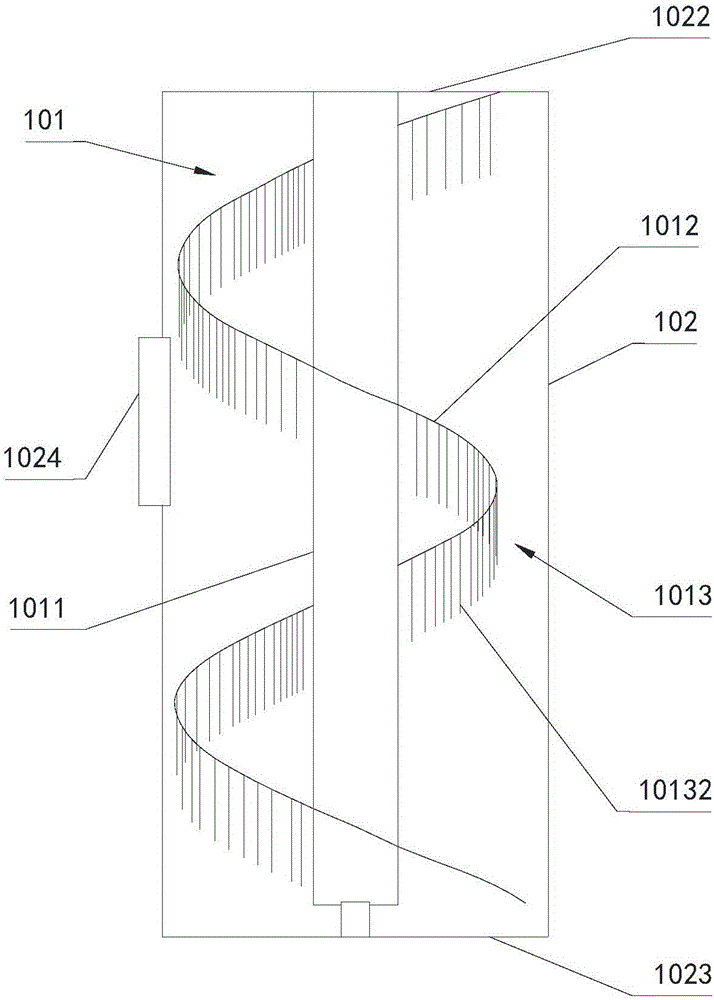

[0055] see Figure 1-Figure 8 As shown, this embodiment provides a kind of unpowered purification equipment for gas particles; figure 1 Schematic diagram of the structure of the non-powered purification equipment for gas particles provided in this embodiment; figure 2 , image 3 Two structural schematic diagrams of the non-powered purification device of the gas particle non-powered purification equipment provided in this embodiment; figure 2 The adsorption packing shown is disc adsorption packing, image 3 The adsorption filler shown is a linear adsorption filler; Figure 4 The schematic diagram of the spiral blade and the rotating shaft provided for this embodiment; Figure 5-Figure 7 The schematic diagram of the adsorption filler provided in this embodiment, wherein, Figure 5 Shown is disc adsorption packing, Figure 6 and Figure 7 It is a linear adsorption filler. Figure 8 It is a schematic diagram of the anti-fall net of the filter element of the non-powered p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com