Coal mine car operation bend traction rail system

A technology for traction tracks and curves, which is applied in the direction of railway vehicle traction devices, tracks, stations, etc., can solve the problems of affecting the transportation efficiency of mine carts, low degree of mechanization, slow operation process, etc. Hidden danger, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

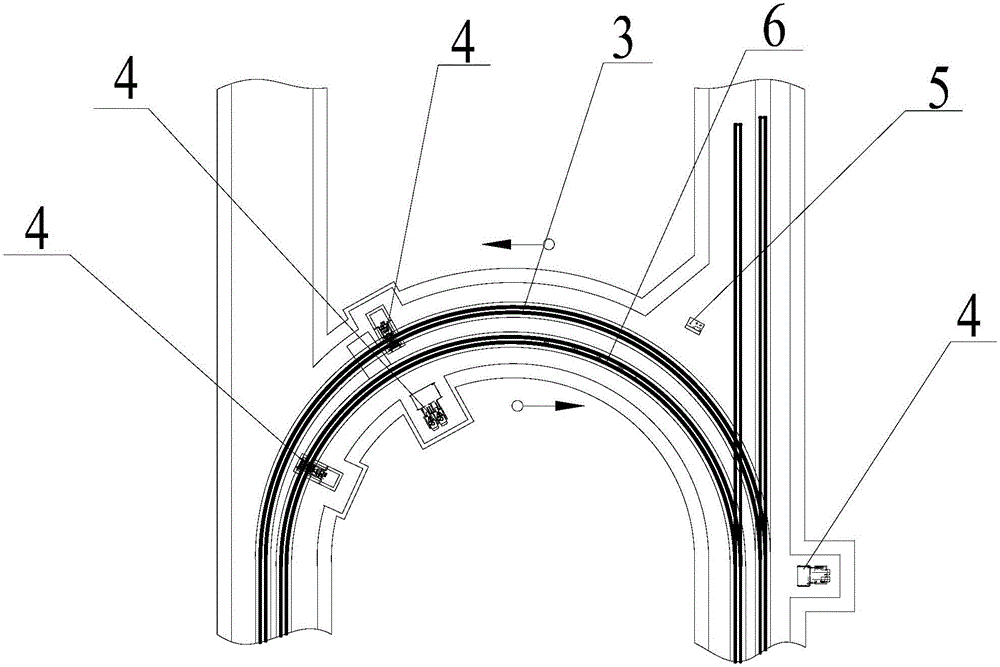

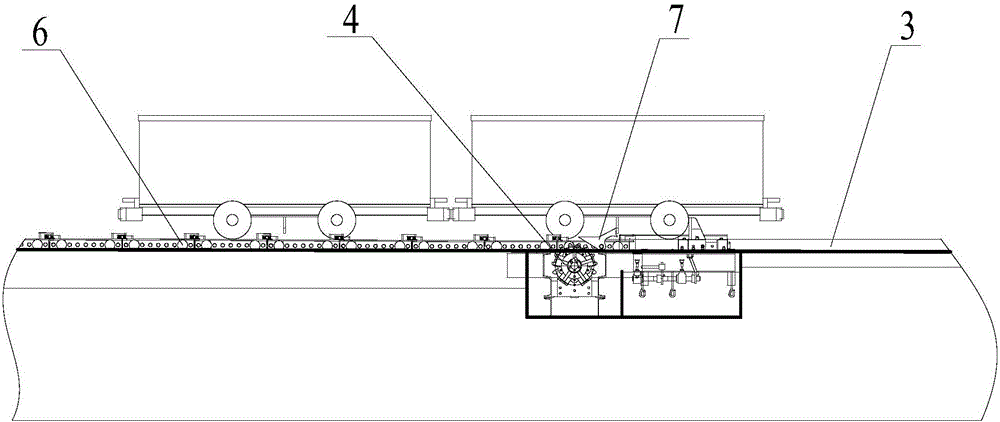

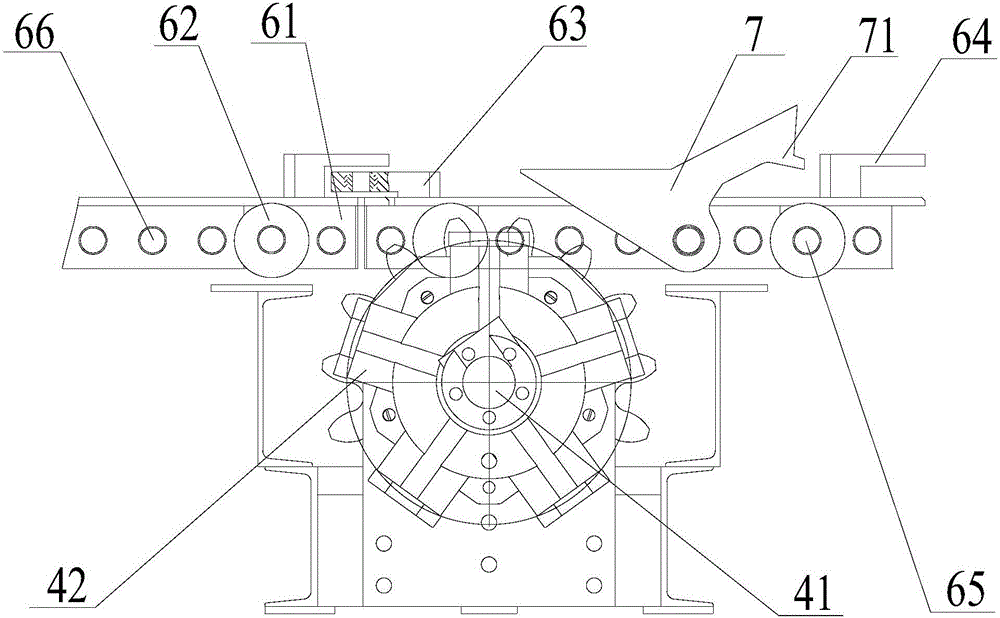

[0020] like Figure 1-5 As shown, a coal mine operation curve traction system is arranged at the curve junction of the horizontal inclined shaft of the coal mine, including two parallel curve rails and an operation console 5, and the center of the curve rails is provided with a traction track groove 3 and a magnet induction device, the traction track groove 3 is provided with a tractor, and the lower part of the traction track groove 3 is provided with a hydraulic transmission device 4; the traction track groove 3 is composed of two rows of U-shaped channel steel notches of the same specification Relatively combined, the tractor is composed of several small-wheeled vehicles 6 front and rear hingedly connected, and the small-wheeled vehicles 6 rotate horizontally along the hinge shaft, and the upper part of the small-wheeled vehicles 6 is provided with a movable push plate 7, so that The bottom of the small wheeled vehicle 6 is provided with a pin tooth member, and the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com