Grading method of cold recycled asphalt concrete

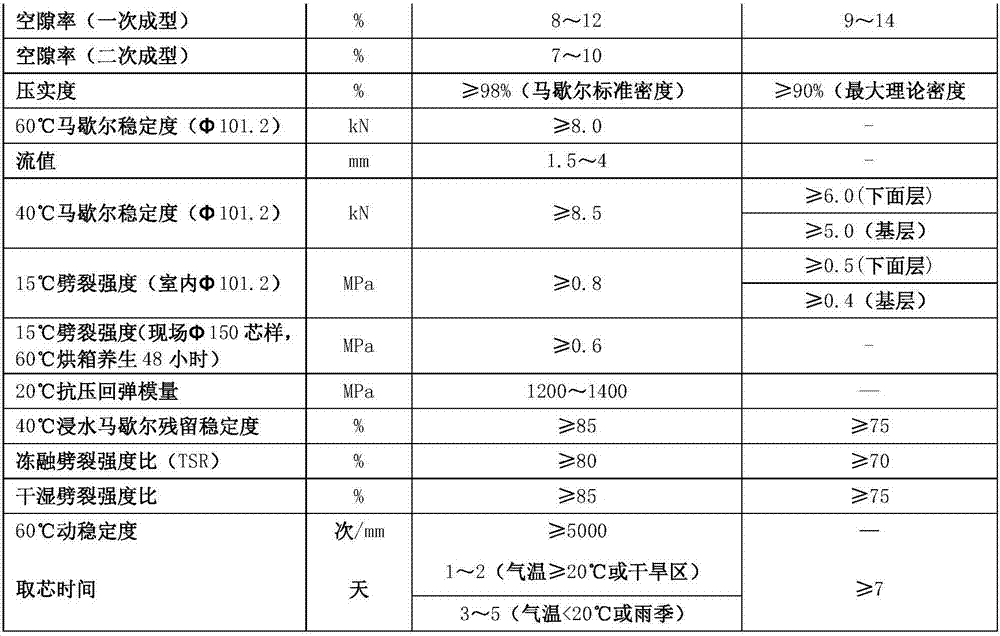

A cold recycling technology for asphalt concrete, which is applied in the field of asphalt concrete, can solve problems such as the inability to achieve broken links, short service life of recycled asphalt concrete, and failure to achieve resonance between new materials and waste materials, so as to improve mechanical properties, strength and toughness, and improve compaction degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

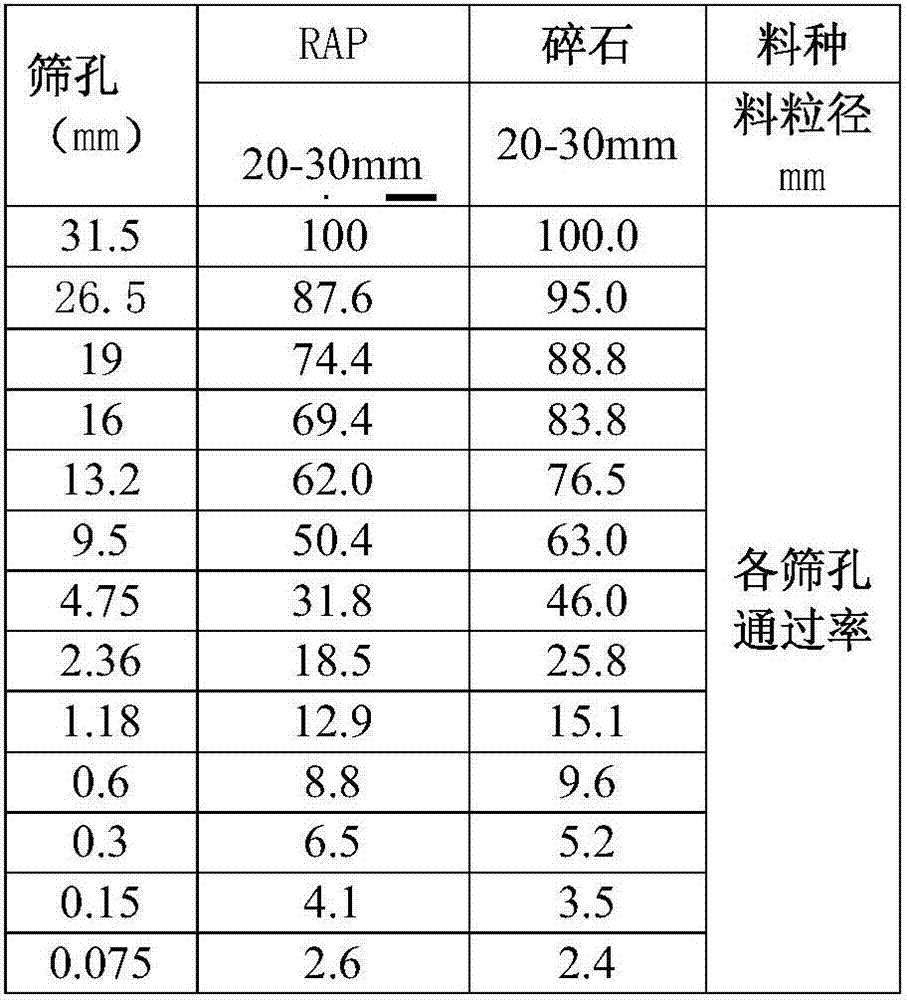

[0040] 1. Preparation of cold recycled concrete:

[0041] Step 1. In kilograms, select the following raw materials in parts by weight: ceramic waste nanoparticles 10 and aluminum waste nanoparticles 1 with a particle size of 50-60 nm; ceramic waste nanoparticles 15 and aluminum waste nanoparticles 3 with a particle size of 100-120 nm ; particle size 0-5mm asphalt pavement reclaimed material 29; particle size 5-10mm asphalt pavement reclaimed material 24; particle size 20-30mm asphalt pavement reclaimed material 27, crushed stone 14 and volcanic stone 8; mineral powder 1, cement 1, emulsified Asphalt 5, water 4, polypropylene fiber 10 and bentonite 1;

[0042] Step 2. Bentonite 1, polypropylene fiber 3, ceramic waste nanoparticles 5 with a particle size of 100-120nm, pottery aluminum waste nanoparticles 1 with a particle size of 100-120nm, ceramic waste nanoparticles 3 with a particle size of 50-60nm, and a particle size of 50 - 60nm aluminum material waste nanoparticles 0.5 a...

example 2

[0058] 1. Preparation of cold recycled concrete:

[0059] Step 1. In kilograms, select the following raw materials in parts by weight: ceramic waste nanoparticles 12 with a particle size of 50-60nm and aluminum waste nanoparticles 1.5; ceramic waste nanoparticles 12 with a particle size of 100-120nm and aluminum waste nanoparticles 4 ; particle size 0-5mm asphalt pavement recycled material 30; particle size 5-10mm asphalt pavement recycled material 25; particle size 20-30mm asphalt pavement recycled material 28, gravel 14-16 and volcanic stone 9; mineral powder 2, cement 2 , emulsified asphalt 6, water 6, polypropylene fiber 13 and bentonite 2;

[0060] Step 2. Bentonite 2, polypropylene fiber 3, ceramic waste nanoparticles 3 with a particle size of 100-120nm, pottery aluminum waste nanoparticles with a particle size of 100-120nm 0.5, ceramic waste nanoparticles 3 with a particle size of 50-60nm, and a particle size of 50 - 60nm aluminum material waste nanoparticles 1 and emu...

example 3

[0076] 1. Preparation of cold recycled concrete:

[0077] Step 1. Select the following raw materials in parts by weight: ceramic waste nanoparticles 15 and aluminum waste nanoparticles 2 with a particle size of 50-60 nm; ceramic waste nanoparticles 20 and aluminum waste nanoparticles 5 with a particle size of 0-120 nm; 5mm asphalt pavement recycled material 31; particle size 5-10mm asphalt pavement recycled material 26; particle size 20-30mm asphalt pavement recycled material 30, particle size 10-20mm crushed stone 16 and volcanic rock 10; mineral powder 3, cement 2, emulsified Asphalt 7, water 7, polypropylene fiber 15 and bentonite 2;

[0078] Step 2. Bentonite 2, polypropylene fiber 5, ceramic waste nanoparticles 5 with a particle size of 100-120nm, pottery aluminum waste nanoparticles 2 with a particle size of 100-120nm, ceramic waste nanoparticles 5 with a particle size of 50-60nm, and ceramic waste nanoparticles with a particle size of 50nm - 60nm aluminum material wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com