Preparation and repair method of permeable concrete

A technology of permeable concrete and high-pressure water, applied in the field of concrete, can solve the problems of reducing the service quality of permeable concrete, extending the application range of service life, low strength of permeable concrete, and high cost, and achieves efficient plugging effect, low difficulty of plugging, and cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

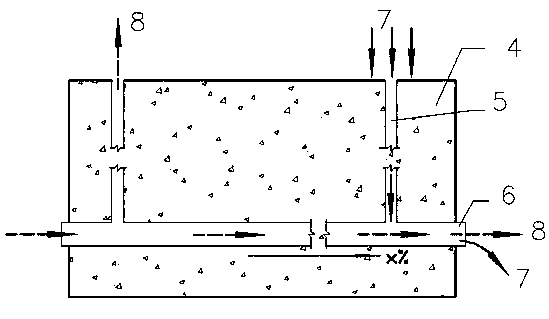

[0022] Preparation of high-performance concrete materials: Weigh 30 parts by weight of 52.5 ordinary Portland cement, 6 parts by weight of silica fume, 8 parts by weight of fly ash, 45 parts by weight of aggregate, 1 part by weight of mineral powder, and 0.1 part by weight of fiber, mix and mix Evenly, at the same time, mix 1 part by weight of high-efficiency water reducer and 10 parts by weight of water, add part of the water and water reducer to the mixer, mix the liquid and all the solid materials and stir at low speed for 2-3min, add the remaining water and water during the stirring process After the water reducer is mixed with the liquid, stir at high speed for about 3 minutes until the mixture has good fluidity;

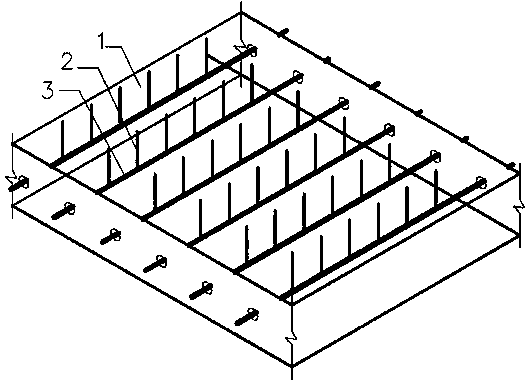

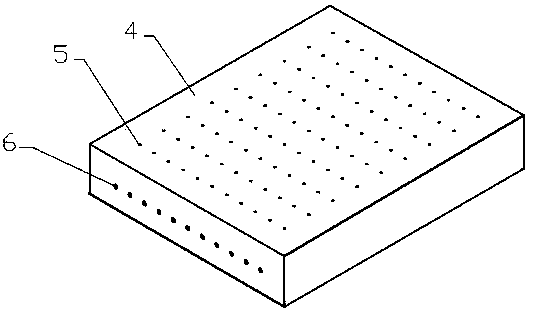

[0023] Hole forming design and mold assembly: In this embodiment, it is determined that the vertical holes and horizontal holes are all circular, with diameters of 3mm and 8mm respectively, and are arranged in a rectangular array;

[0024] Pouring molding: Pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com