Yarn spinning process of high-count combed pure mohair knitted yarns

A knitting yarn and combing technology, which is applied in the spinning process of high-count combed pure mohair knitting yarn, can solve the problems of difficult production, low production rate, and poor cohesion, and achieve fine, smooth, and smooth garments. Thin, smooth and soft tones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

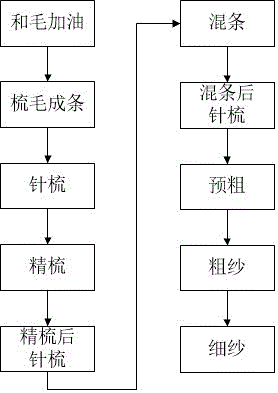

[0056] The spinning process of 36-count combed pure mohair knitting yarn includes the following procedures:

[0057] (1) Hemao refueling: Spray Hemao oil and antistatic agent layer by layer on the mohair fiber, add 0.4% Hemao oil, 0.2% antistatic agent, 0.1% cohesive agent, add 19% water, and control the moisture regain to 22-23% , balanced for 24 hours; (2) Combing into strips: Carding distance: 2.2mm, 2.0mm, 1.5mm, 1.3mm, 1.1mm, 1.0mm, 1.2mm from before to after feeding; feeding roller speed 2.2 rpm / min, big cylinder 57rpm, head chest 20rpm, second chest 30rpm, doffer speed 6rpm, transfer roller speed 120rpm, work roll 6rpm, control the delivery 15g / m; (3) Head needle: feeding number 8, drafting multiple 4.8 times, gauge distance 38mm, speed 60m / min, sliver quantity 25g / m; (4) Second needle: feeding number 3 Roots, drafting multiple 4.4 times, gauge 38mm, speed 45m / min, sliver weight 17g / m; (5) Combing: feed 12 roots, draft multiple 13.6 times, gauge 32mm, speed 120 tongs ...

Embodiment 2

[0059] The spinning process of 30 public count combed pure mohair knitting yarn includes the following procedures:

[0060] (1) Hemao refueling: Spray Hemao oil and antistatic agent layer by layer on the mohair fiber, add 0.4% Hemao oil, 0.2% antistatic agent, 0.1% cohesive agent, add 19% water, and control the moisture regain to 22-23% , balanced for 24 hours; (2) Combing into strips: Carding distance: 2.2mm, 2.0mm, 1.5mm, 1.3mm, 1.1mm, 1.0mm, 1.2mm from before to after feeding; feeding roller speed 2.2 rpm / min, big cylinder 57rpm, head chest 20rpm, second chest 30rpm, doffer speed 6rpm, transfer roller speed 120rpm, work roll 6rpm, control the delivery 15g / m; (3) Head needle: feeding number 8, drafting multiple 4.8 times, gauge distance 38mm, speed 60m / min, sliver quantity 25g / m; (4) Second needle: feeding number 3 root, drafting multiple 4.4 times, gauge 38mm, speed 45m / min, sliver weight 17g / m; (5) combing: feed 12 root, draft multiple 13.6 times, gauge 32mm, speed 130 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com