High-speed hosiery machine

A sock machine, high-speed technology, used in textiles and papermaking, weft knitting, knitting and other directions, can solve the problems of unfavorable high-speed sock machine, long yarn path, inability to keep up with high-speed production rhythm, etc. The effect of improved sensitivity, reduced misoperation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below:

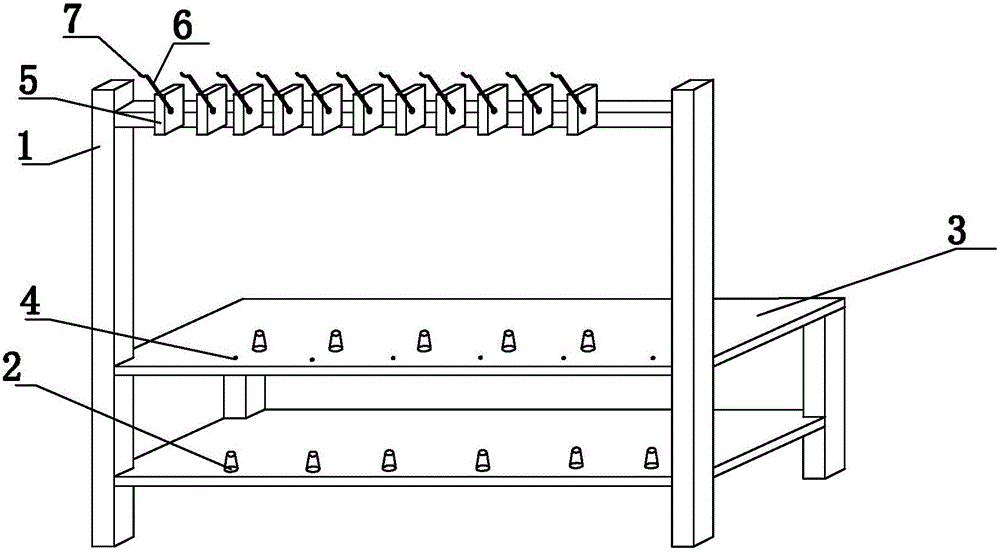

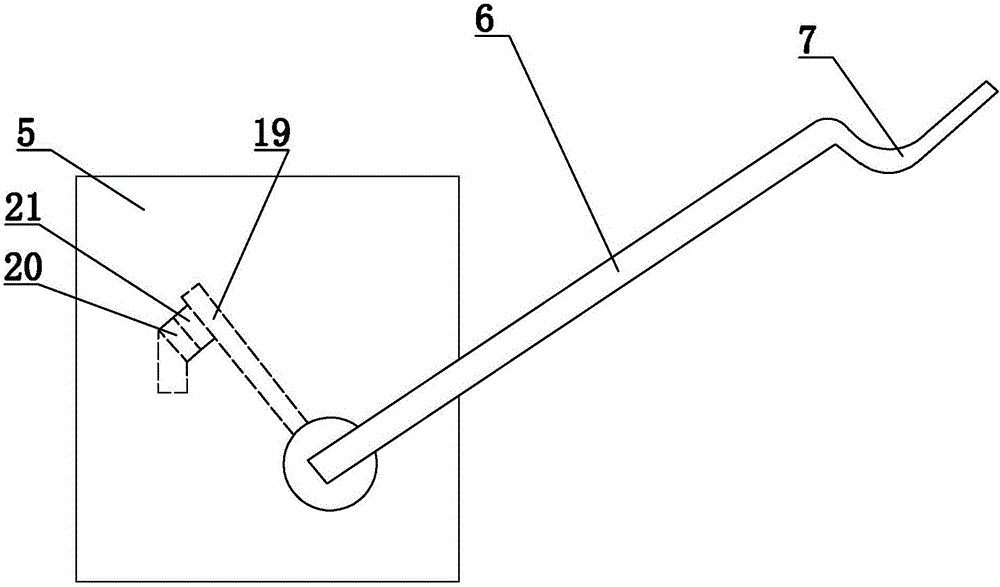

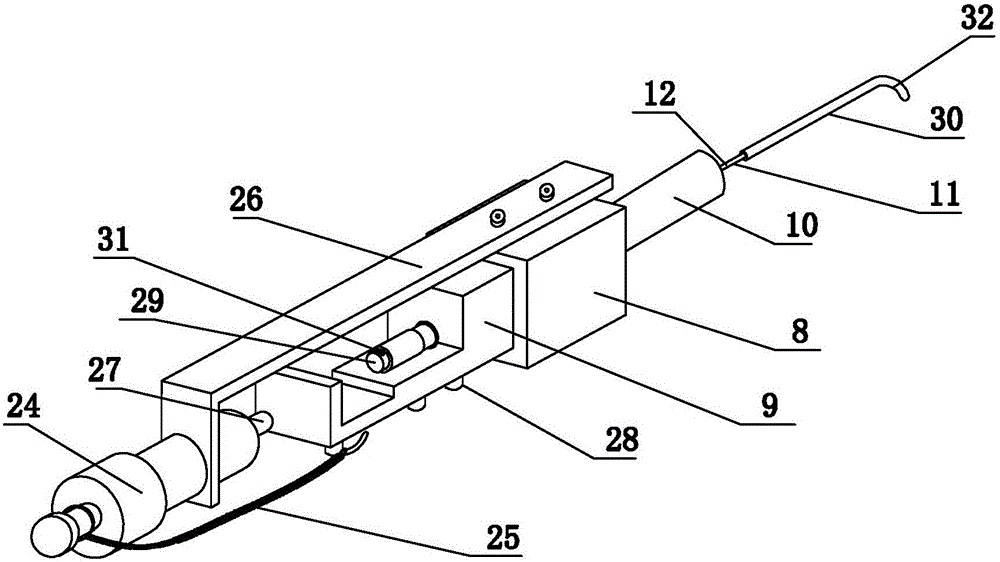

[0027] The present invention is a high-speed hosiery machine, which includes a yarn feeding mechanism for supplying yarn to the knitting mechanism and a control mechanism for controlling the knitting mechanism. A plurality of pallets 3 distributed sequentially from bottom to top, each pallet 3 is provided with a bobbin seat 2, except for the bobbin seat 2 on the uppermost layer, the bobbin seats 2 on the pallets 3 of other layers, other Each supporting plate 3 above is provided with the lead hole 4 that is used to guide this bobbin seat 2, and a plurality of mechanical switches 5 are arranged on the uppermost supporting plate 3, and this mechanical switch 5 is provided with fork 6, and the fork 6 One end is the hanging thread end 7, and the other end of the swing bar 6 is connected to the mechanical switch 5 in rotation, and the swing link 6 is connected with a reset mechanism, which is used to drive the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com