Method for prefabricating box girder adjustable reinforcement cage binding jig frame through stub matching method

A technology of steel bar binding and short-line matching, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., to achieve the effects of long length, avoiding heavy work, and high-altitude risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

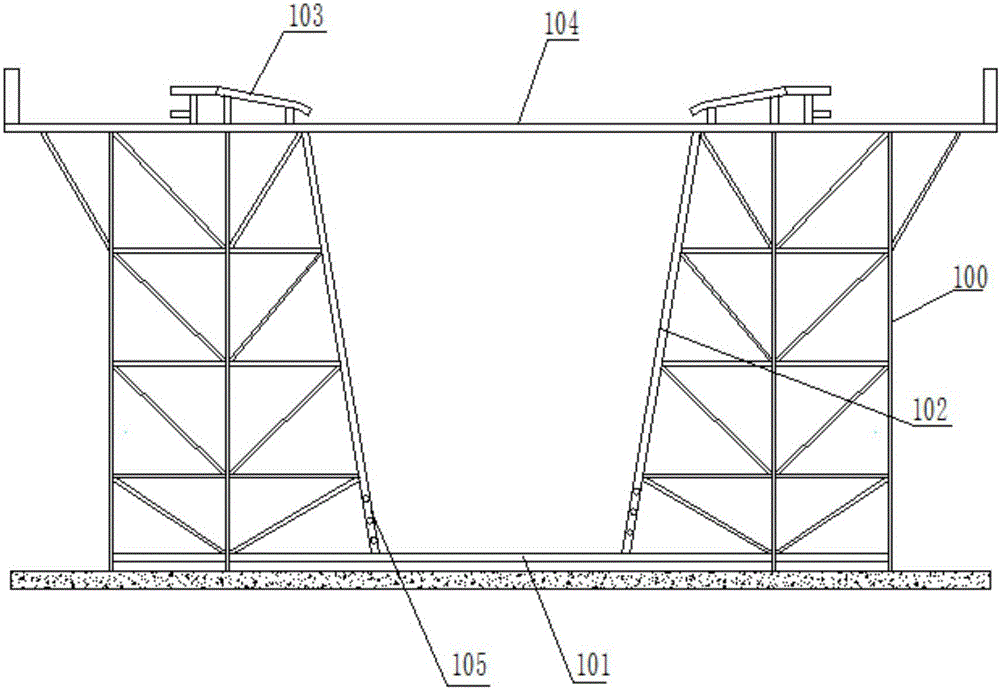

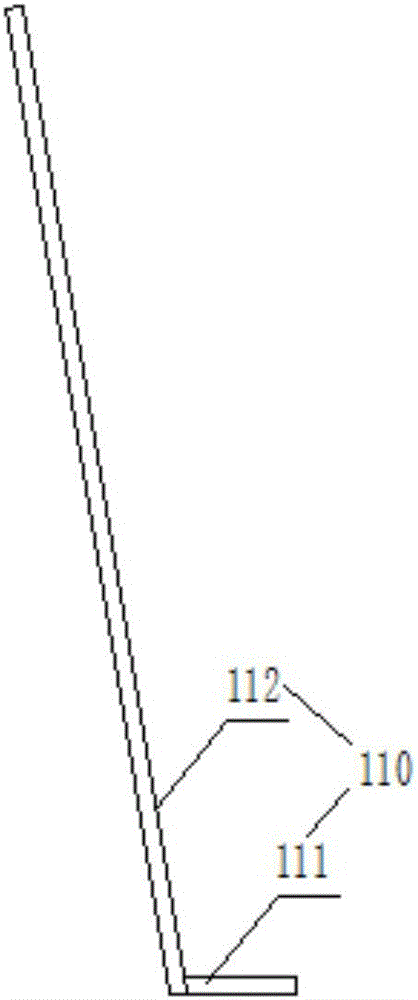

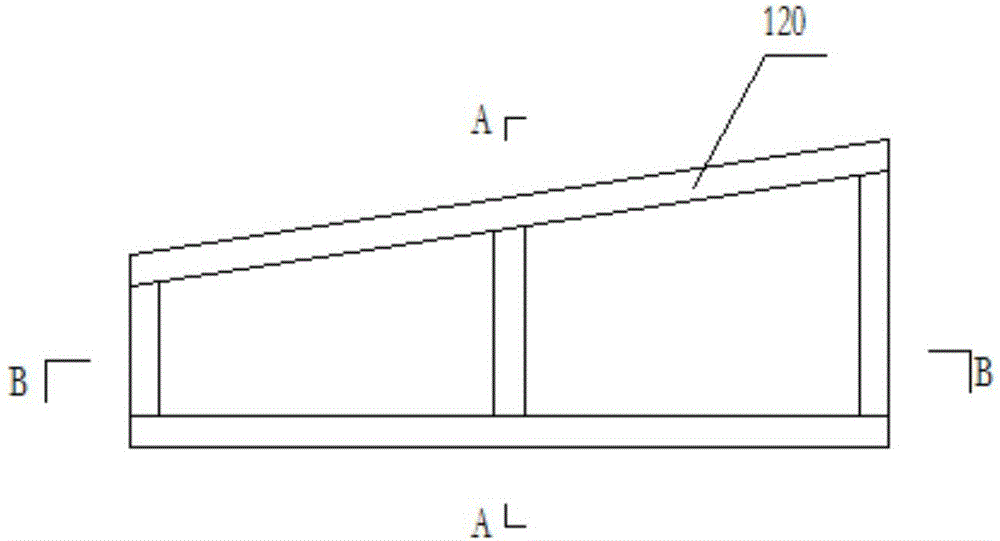

[0042] Such as Figure 1 to Figure 12 As shown, the present invention provides a method for prefabricating a box girder with an adjustable steel cage binding tire frame by a short-line matching method, which is used for prefabricating a box girder with a high height on the main tire frame 100, and the bottom plate, web plate, and roof plate have variable cross-sections. Steel cage tire frame, the steel cage bound on the main tire frame 100 corresponds to the box girder produced on the corresponding prefabricated pedestal.

[0043] The Hong Kong section of the Hong Kong-Zhuhai-Macao Bridge has a bridge span of 25 girders. From the first to the 25th girder, the height and span differ greatly. 5 tying stands, that is, 100 of 5 main tire frames will be constructed.

[0044] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com