Intake manifold secondary gas distribution via structural posts

一种进气歧管、支柱的技术,应用在燃料空气进气口、燃烧空气/燃烧-空气处理、装料系统等方向,能够解决连接至外部装置困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

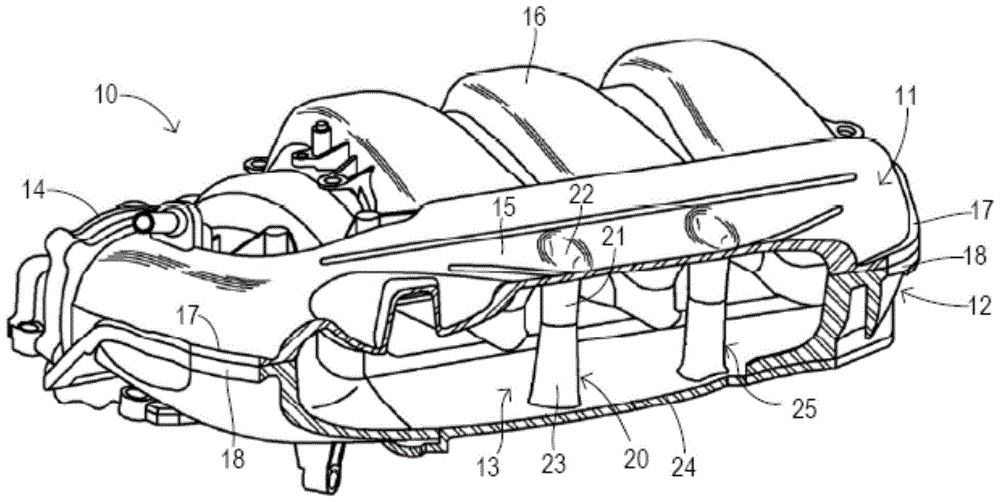

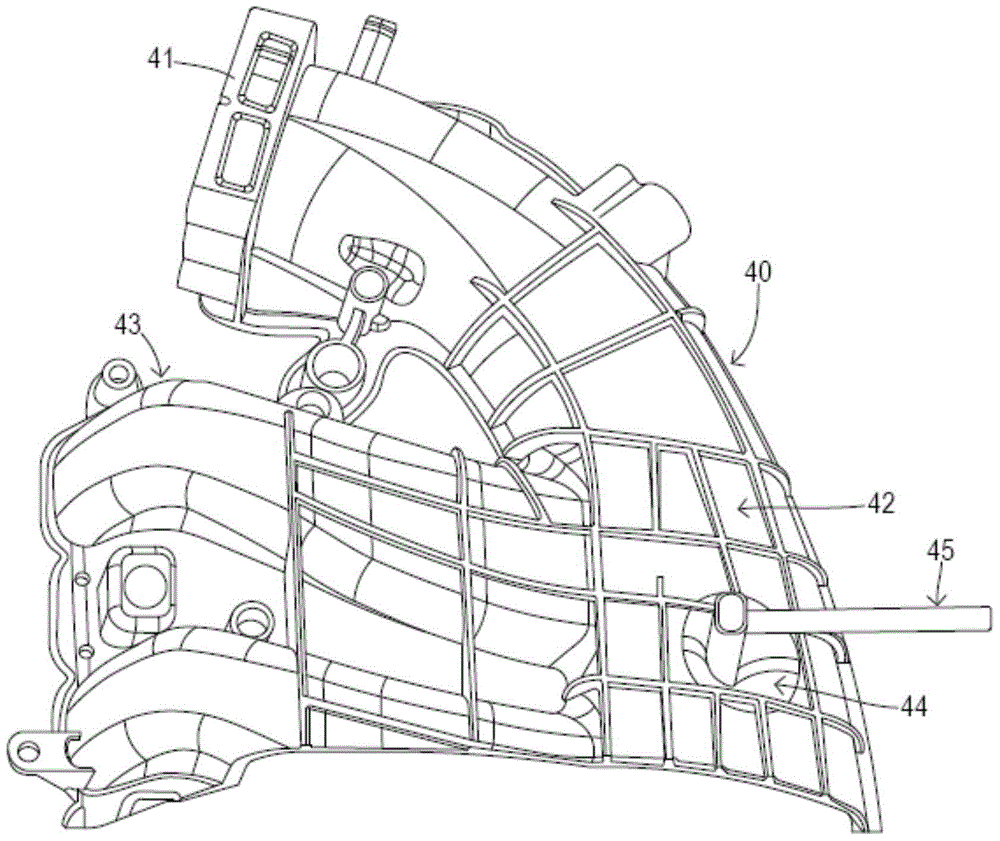

[0016] refer to figure 1 , the intake manifold 10 has an upper housing member 11 and a lower housing member 12 defining a cavity 13 . Housing members 11 and 12 further define inlet 14 (inlet 14 receives the fuel / air mixture via the throttle body), plenum portion 15, and runner portion 16, wherein runner portion 16 has a plurality of runners for The air chambers are fluidly connected with corresponding engine cylinders (not shown). The upper housing member 11 and the lower housing member 12 are connected at a first outer flange 17 and a second outer flange 18 . Two struts 20 and 25 extend through the plenum portion of cavity 13 between housing members 11 and 12 to provide support to reduce vibration of manifold 10 .

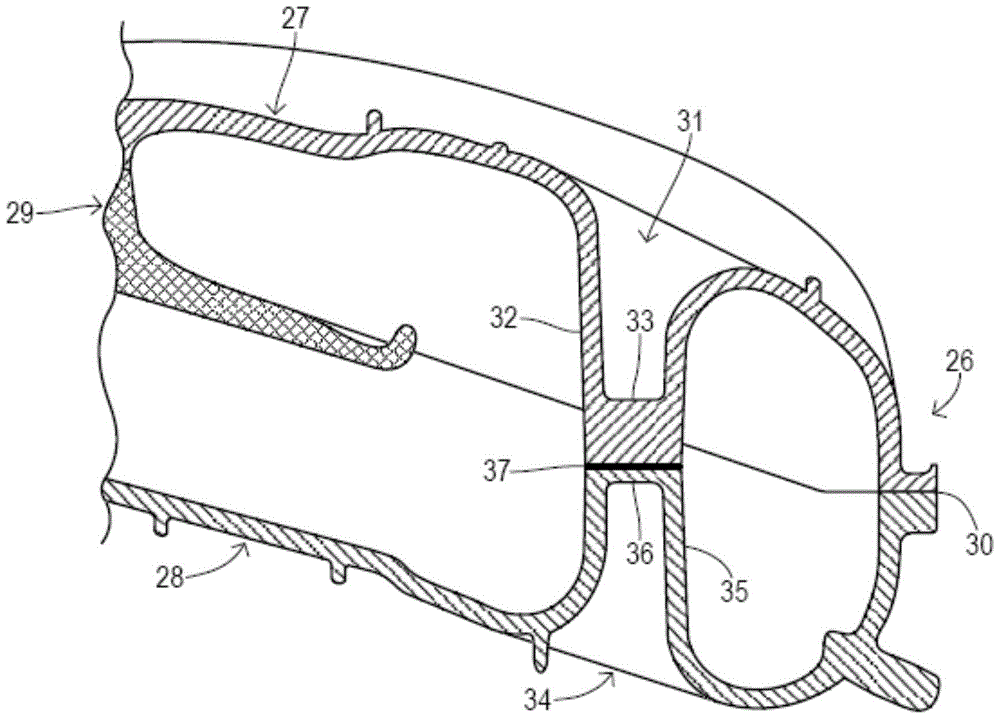

[0017] The strut 20 has an upper strut portion 21 formed as a recess 22 recessed into the outer surface of the plenum portion 15 . The strut 20 has a lower strut portion 23 formed as a depression in an outer surface 24 of the lower housing member 12 . Flanges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com