Scroll compressor

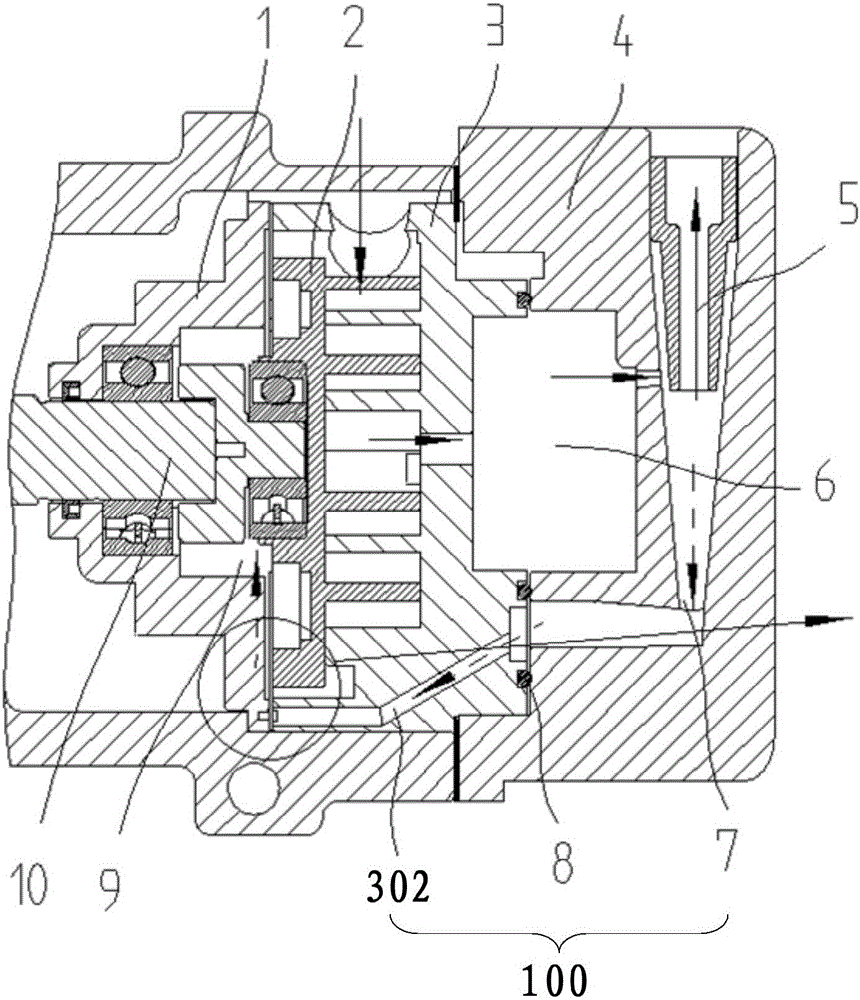

A scroll compressor and a stationary scroll technology, applied in the field of compressors, can solve problems such as unfavorable lubricating oil passage, pores easily blocked by impurities, and increased processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

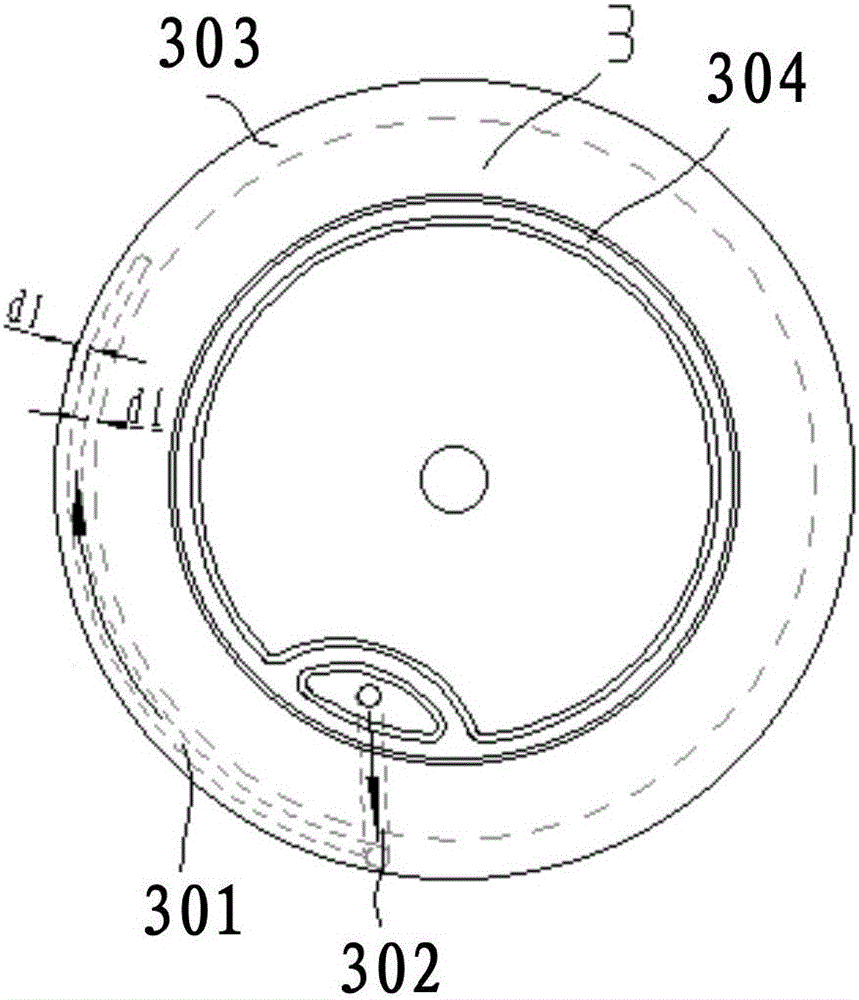

[0054] see Figure 3a to Figure 3c The technical solution of the second embodiment has the following differences from the technical solution of the first embodiment above: In this embodiment, the sub-channel 108 is only provided on the peripheral edge of the fixed scroll 3 .

[0055] see Figure 3a to Figure 3c , the subchannel 108 includes a first throttling groove 301 disposed on the peripheral edge of the fixed scroll 3 . The first throttling groove 301 is arranged inside the fixed scroll 3 and the radian of the first throttling groove 301 is consistent with the radian of the fixed scroll 3 . The peripheral edge of the fixed scroll 3 is a first boss 303 , and the first throttling groove 301 is arranged inside the first boss 303 . The channel 100 also includes a first introduction hole 302 provided on the fixed scroll 3 and a second introduction hole 102 provided on the bracket 1 . Wherein, the fluid flows to the back pressure chamber 9 through the exhaust chamber 6 , the...

Embodiment 3

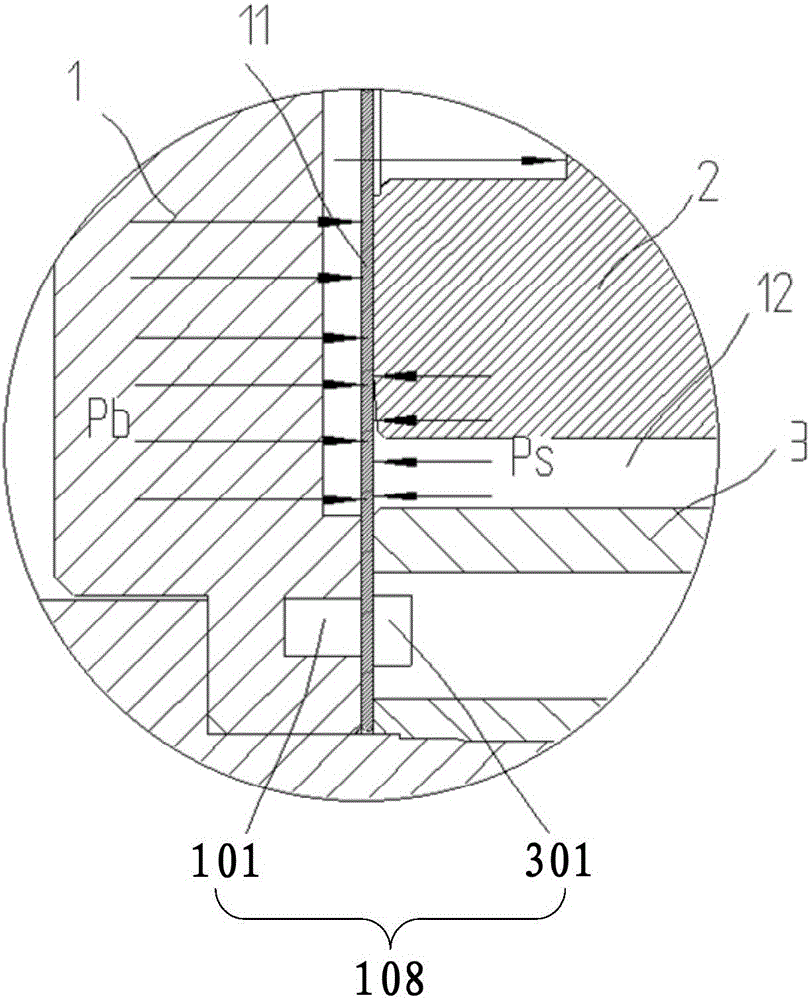

[0058] see Figure 4a to Figure 4c , the technical solution of the third embodiment has the following differences from the technical solution of the first embodiment above: In this embodiment, the sub-channel 108 is only provided on the peripheral edge of the bracket 1 . Figure 4c The middle arrows indicate the introduction of back pressure fluid flow paths.

[0059] Such as Figure 4a to Figure 4c As shown, the sub-channel 108 includes a second throttling groove 101 disposed on the peripheral edge of the bracket 1 , the second throttling groove 101 is disposed inside the bracket 1 and the arc of the second throttling groove 101 is consistent with the arc of the bracket 1 . The peripheral edge of the bracket 1 is a second boss 103 , and the second throttling groove 101 is arranged inside the second boss 103 . The channel 100 also includes a first introduction hole 302 provided on the fixed scroll 3 and a second introduction hole 102 provided on the bracket 1 . Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com