Operation-condition-adjustable water-jet propulsion pump

A technology of water jet propulsion and operating conditions, applied in the field of hydraulic machinery, can solve the problems of wasting energy, unadjustable flow parameters, and affecting propulsion efficiency, etc., and achieve the effects of improving propulsion efficiency, easy control, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

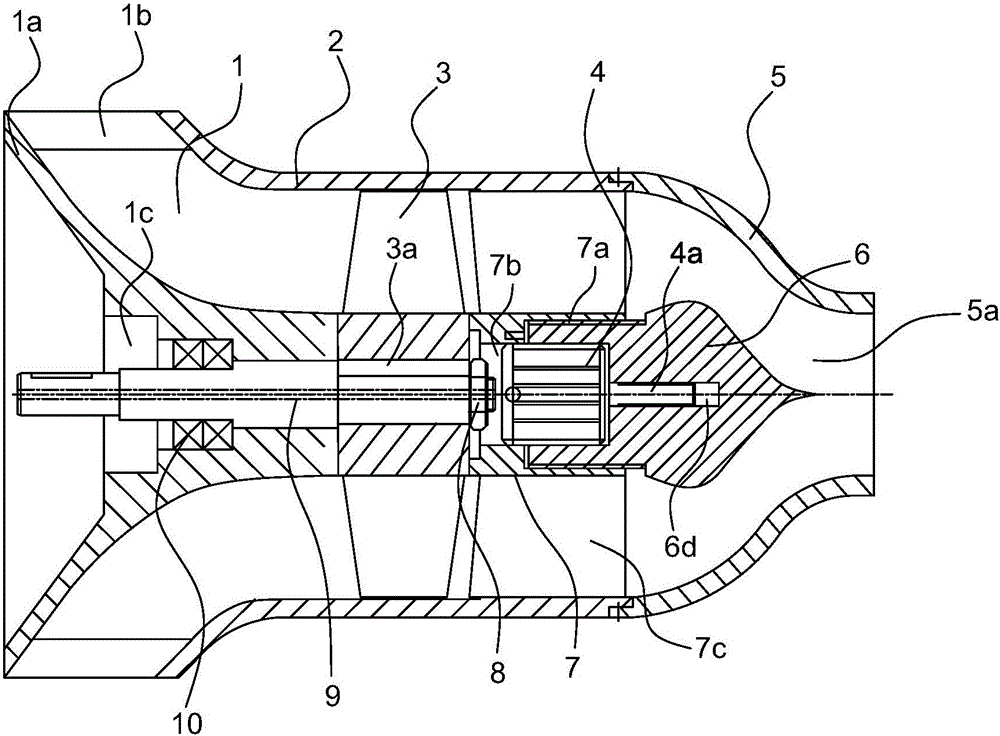

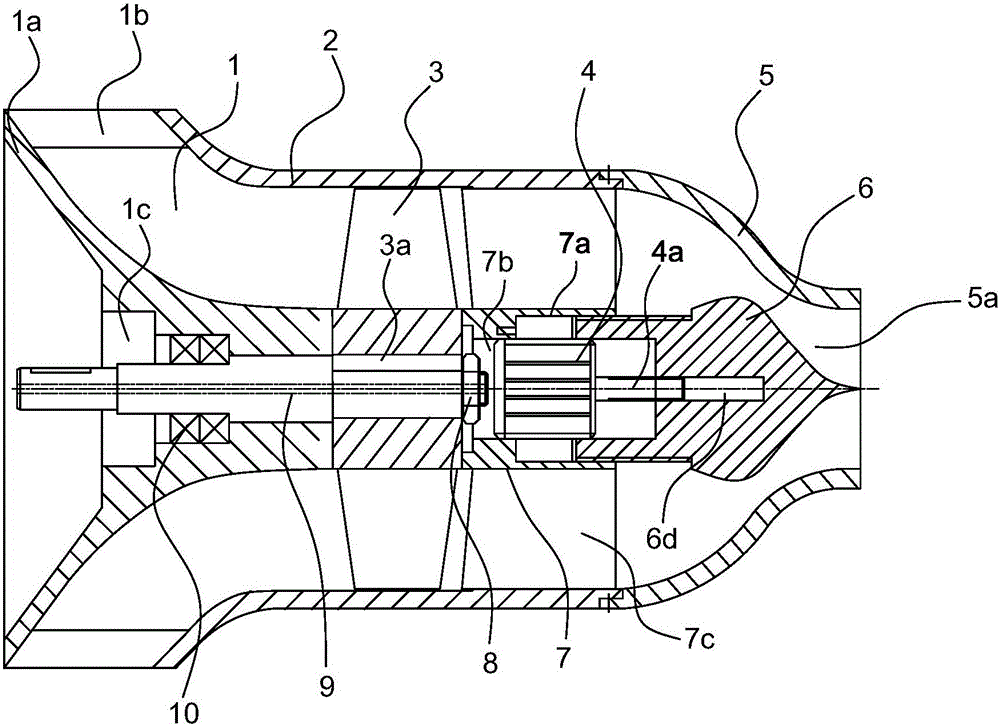

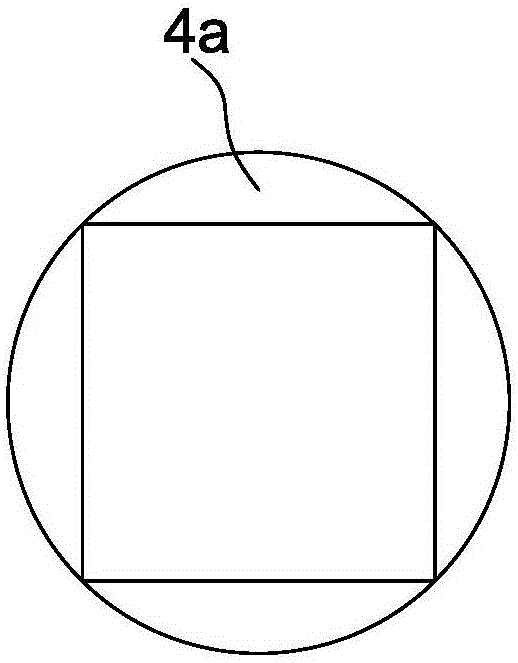

[0036] For ease of understanding, combined here Figure 1~4 The overall assembly components and working process of the water jet propulsion pump with adjustable operating conditions are described as follows:

[0037] Such as figure 1 , 2 As shown, a water jet propulsion pump with adjustable operating conditions includes a pump body. The pump body includes a pump casing 2 and a nozzle 5 that are fixedly connected to each other. The pump casing 2 is provided with a support for installing the pump shaft 9. Seat 1a, the pump shaft 9 is fixed in the support seat 1a through the bearing 10, the water inlet channel 1 is formed between the inner wall of the pump casing and the support seat 1a; the water inlet flow channel 1 is formed between the pump casing 2 and the support seat 1a There are rectifying plates 1b connected to each other at the water inlet; the water inlet of the water inlet channel 1 is arranged in an inclined shape relative to the axis of the pump shaft.

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com