Temperature-sensor-free ultrasonic flow meter

A technology of temperature sensor and flow measurement, which is applied in the measurement of flow/mass flow, liquid/fluid solid measurement, instruments, etc. It can solve the problems of inaccurate measurement and achieve the effect of low cost of electronic hardware, low cost and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

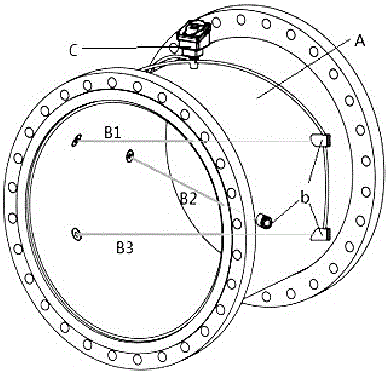

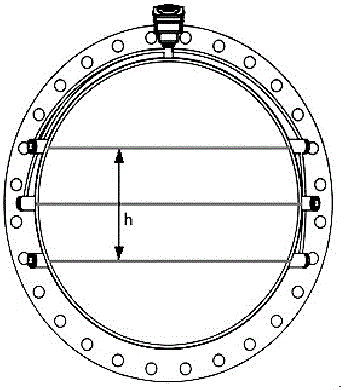

[0038] Embodiment 1: as attached figure 1 , 2 As shown, the ultrasonic instrument of DN150 is selected, the inner cavity of the measuring tube is cylindrical, the maximum flow rate in the measuring tube is 312m3 / h, the inner diameter of the tube is 150mm, and the sound channel of a group of transducers is 30 meters away from the axis of the measuring tube. °-45°, installed on the center channel, and the other two sets of transducers are 20°-70° to the axis of the measuring tube, respectively installed on the upper channel and the lower channel, the upper channel or the lower channel The height difference from the horizontal channel is 30mm, that is, the distance between the two is 60mm,

[0039]When measuring and calculating, the totalizer first measures the reciprocating time of the three sets of transducers B1, B2, and B3 instantaneously.

[0040] That is: 1. Measure the reciprocating time of the fluid entering the center of the measuring tube through a group of transducer...

Embodiment 2

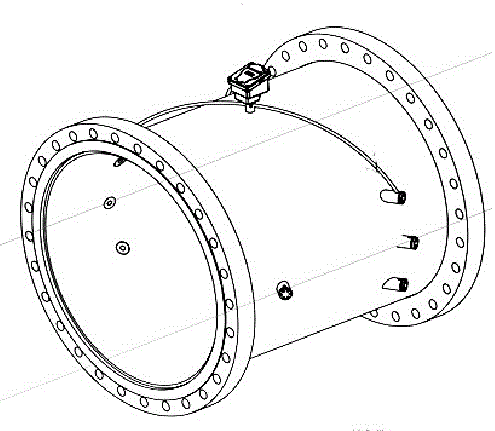

[0050] Embodiment 2: as attached image 3 As shown, the ultrasonic instrument of DN150 is selected, the inner cavity of the measuring tube is cylindrical, four sets of transducers are arranged on the measuring tube, the maximum flow rate in the measuring tube is 312m3 / h, and the inner diameter of the tube is 150mm , the sound channel of a group of transducers B2 is 60° to the axis of the measuring tube, and the other group of transducers B4 and B2 are installed crosswise, 120° to the axis of the pipeline, all installed in the center acoustic On the channel, the other two sets of transducers are 60° to the axis of the measuring tube, installed on the upper channel and the lower channel respectively, and the other two sets of transducers B1 and B3 are respectively installed on the upper channel and the lower channel There is a 45mm height difference between the upper channel and the lower channel from the horizontal channel, that is, the distance between the two is 90mm.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com