Pre-tightening device and method of piezoelectric ceramic drivers in fast reflecting mirror system

A technology of fast mirrors and piezoelectric ceramics, applied in the direction of instruments, optical components, optics, etc., can solve the problems that the influence of tensile performance and dynamic push-pull characteristics cannot be judged and controlled in advance, so as to improve dynamic push-pull performance and reduce disadvantages Influence and improve the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

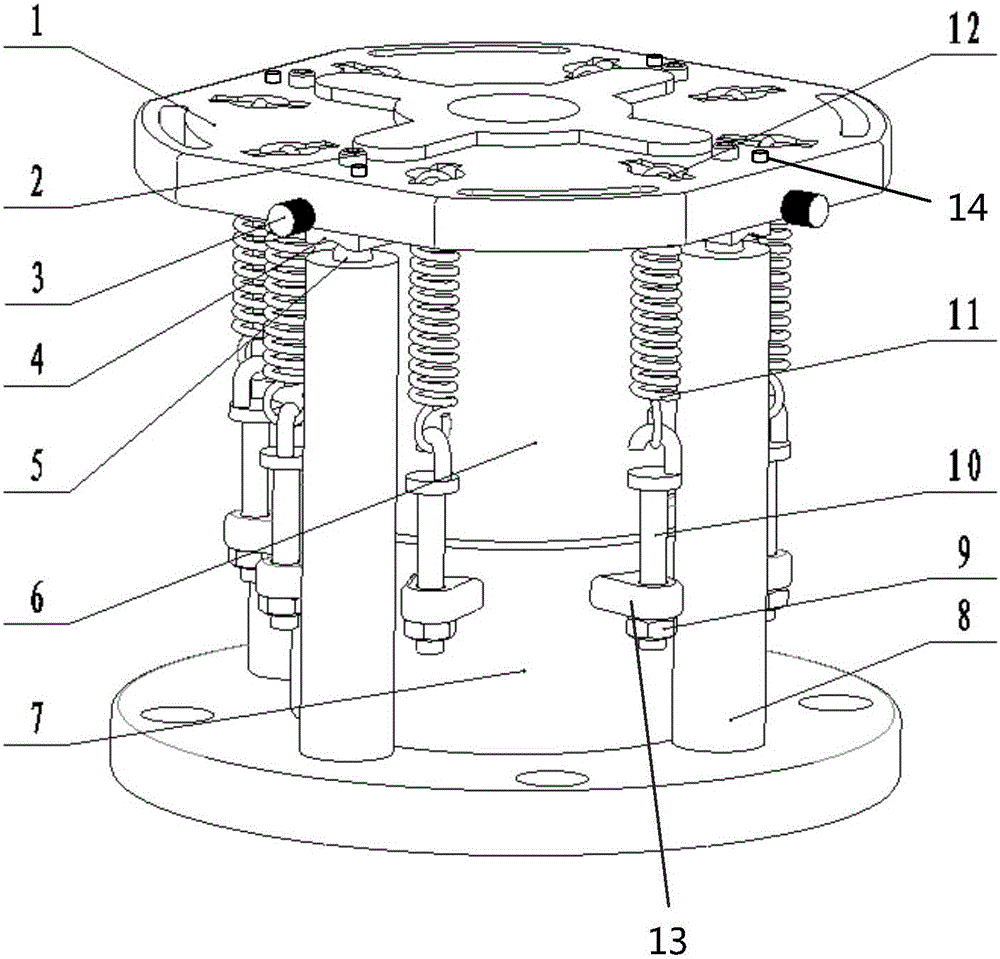

[0053] figure 1 It is a structural schematic diagram of the present invention installed behind the fast mirror system, figure 1 The fast mirror shown has 4 piezo drivers.

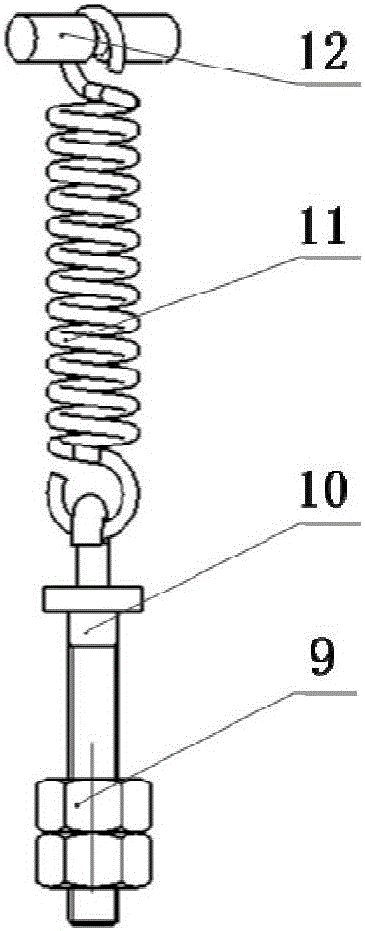

[0054] Such as figure 1 As shown, the pretensioning device of the piezoelectric ceramic driver in the fast mirror system provided by the present invention includes 4 sets of differential fine-tuning locking assemblies, 4 sets of spring preloading assemblies and 4 sets of displacement sensors 14 .

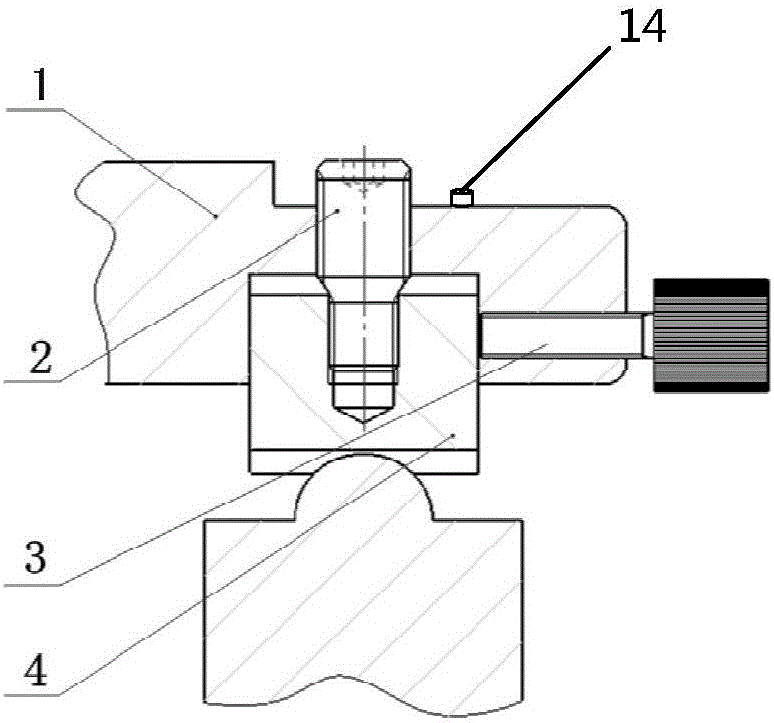

[0055] Each set of differential fine-tuning locking components includes a differential screw 2, a contact block 4 and a locking jack screw 3; the differential screw 2 is mounted on the mirror base 1 of the fast mirror through thread fit; the contact block 4 is located on the piezoelectric ceramic driver Between the hemispherical top 5 on the top and the differential screw 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com