Gas insulated metal enclosed switchgear

A technology of enclosing switchgear and gas-insulated metal, which is applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems of circuit breaker room failure, outstanding safety hazards, failure to achieve rapid maintenance of equipment and rapid recovery of operation, etc. , to prevent the entry of small animals and improve the performance of the protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

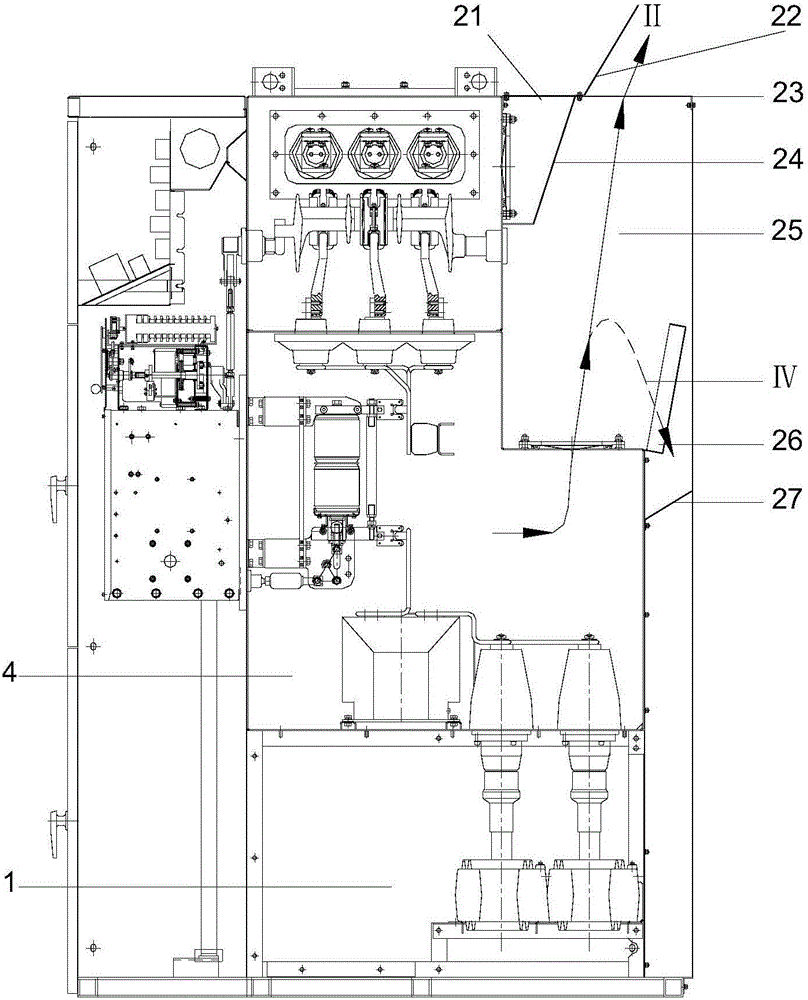

[0057] Such as Figure 2 to Figure 1 As shown in 1, the gas-insulated metal-enclosed switchgear embodiment of the present invention is provided with a busbar room 10, a circuit breaker room 4 and a cable room 1. The busbar chamber 10 is provided with a busbar chamber pressure relief window A, and the circuit breaker chamber is provided with a circuit breaker pressure relief window B. The pressure relief windows A and B are both connected to an upward pressure relief channel, and the pressure relief channel passes through the top of the cabinet top. The cover pressure relief hole is connected to the atmosphere.

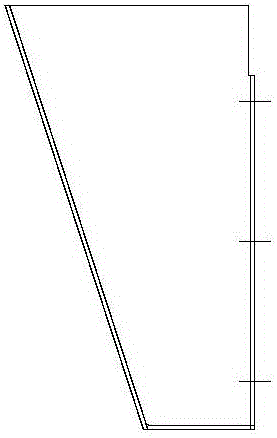

[0058] see figure 2 with Figure 6-1 to Figure 6-3 , A bus chamber pressure release port is separated from the top cover pressure relief hole, and outside the bus chamber pressure release window A, a trumpet-shaped pressure release channel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com