Engine cooling module

一种冷却模、引擎的技术,应用在电动组件、机电装置、电气元件等方向,能够解决影响冷却模组应用场合、影响引擎冷却模组销售规模、整体成本增高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

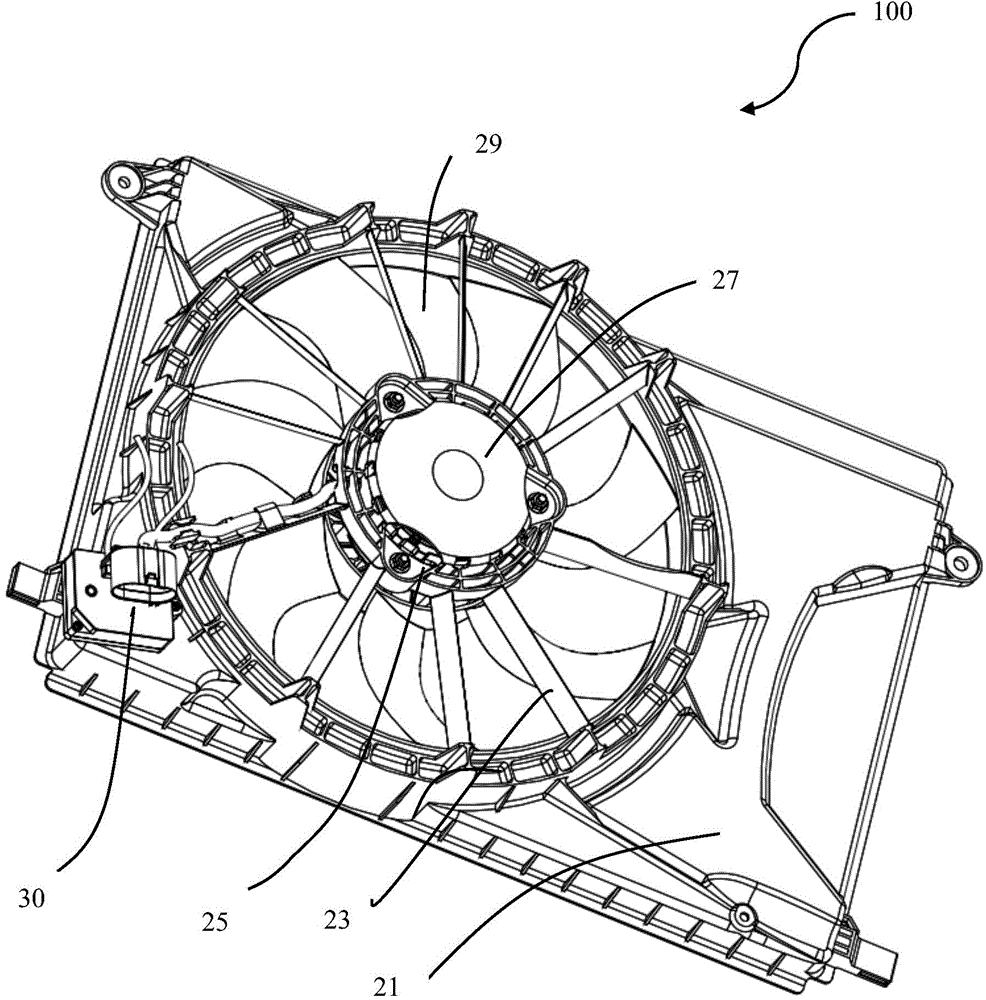

[0025] reference figure 1 The engine cooling module 100 provided by the present invention includes a fan cover 21, a motor 27 mounted to the fan cover 21, an impeller 29 mounted to the output shaft of the motor 27, and a motor speed regulating device 30 mounted to the fan cover 21. Specifically, the fan cover 21 is provided with a vent hole with a larger area, and is also provided with a plurality of spokes 23 extending toward the center of the vent hole, and a hub 25 is fixed at the end of the spoke 23. The motor 27 is mounted to the hub 25, and the impeller 29 is mounted to the output shaft of the motor 27 and rotates with the output shaft. The motor 27 and the impeller 29 are housed in the aforementioned ventilation holes.

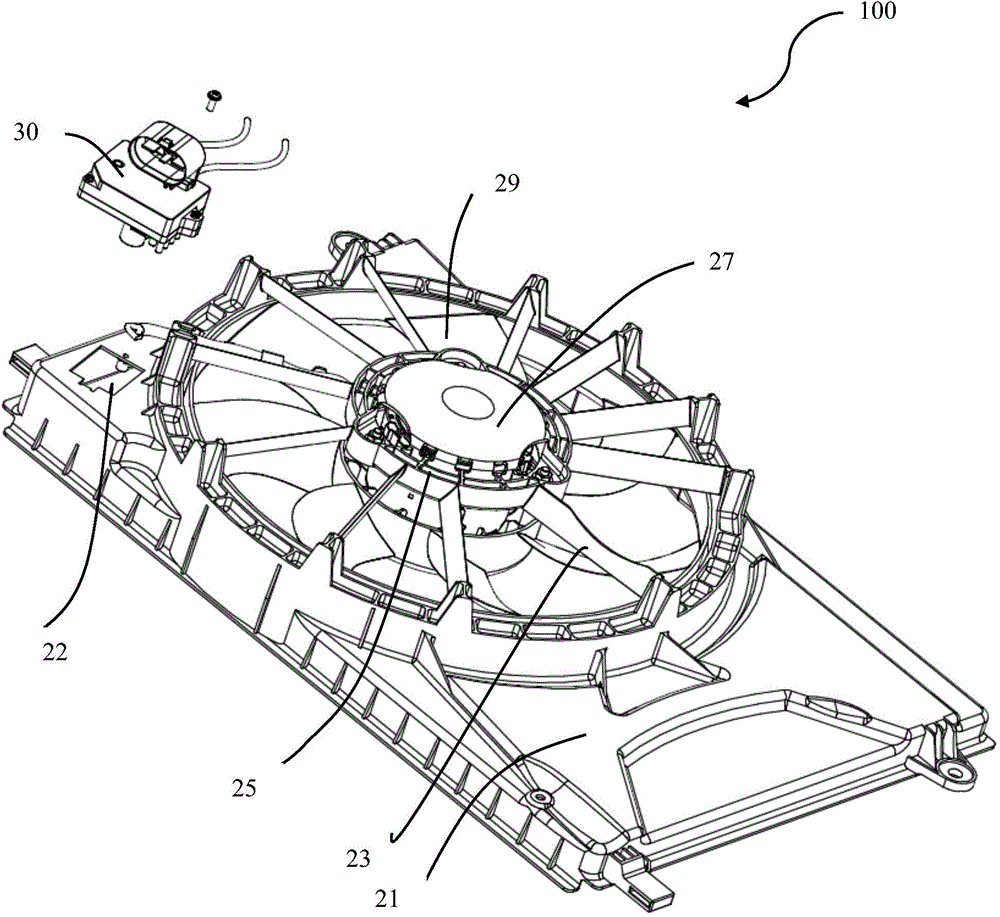

[0026] reference figure 2 The fan cover 21 has a recess 22 for installing the motor speed regulating device 30. In terms of circuit connection, the motor speed regulating device 30 is connected in series between the power supply and the motor 27, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com