Drive arrangement

A technology of driving device and transmission device, applied in the direction of transmission device, fluid transmission device, electromechanical device, etc., to achieve the effect of high cost, small external size, and shortened production interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

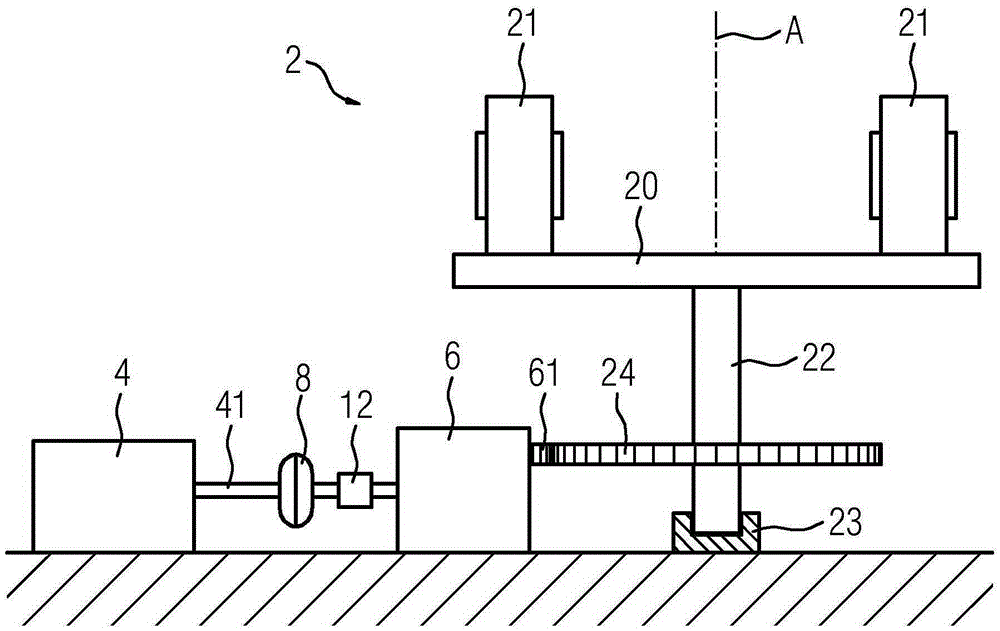

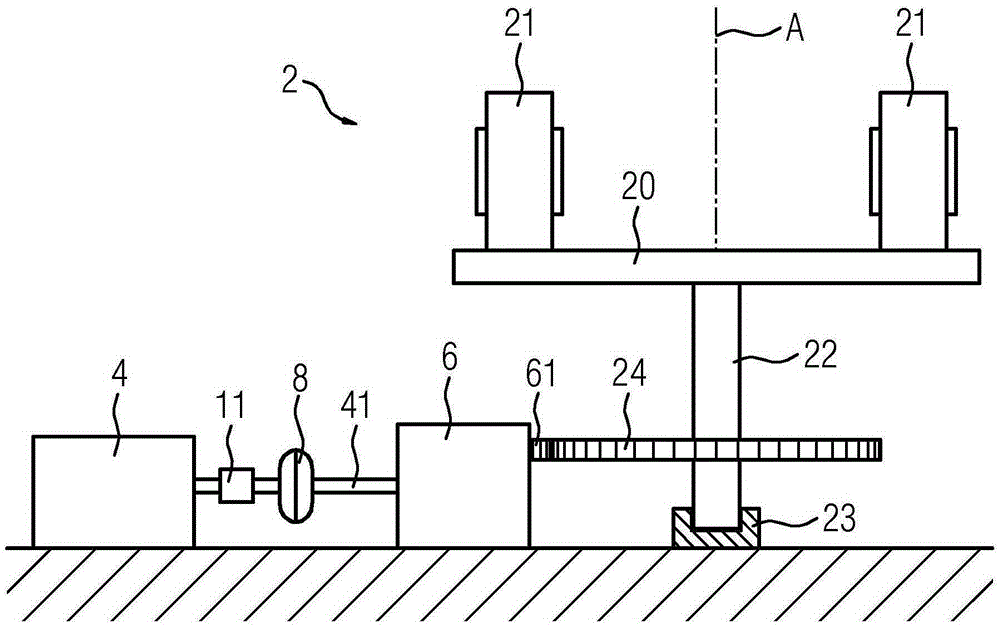

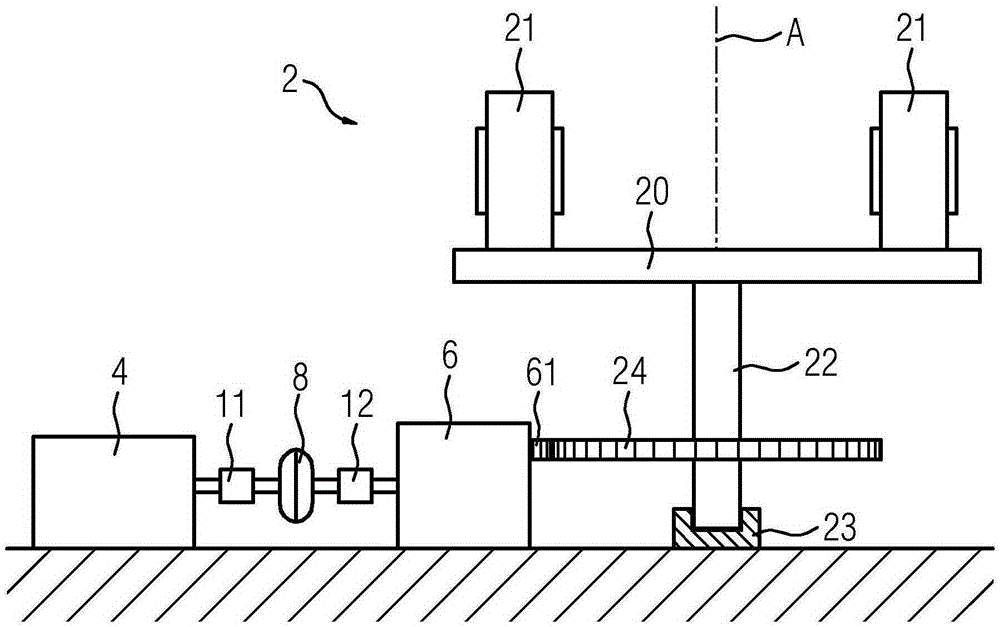

[0048] figure 1 A section through a drive for driving the vertical mill 2 is shown, wherein a torque transmission element 12 is arranged between the hydrodynamic clutch 8 and the vertical mill 2 .

[0049] The vertical grinding machine 2 functioning as a working machine has a grinding disc 20 , which is rotatable about a vertical axis A of rotation. On the upper side of the grinding disc 20 a lining is formed, on which one or more grinding rollers 21 roll. The grinding disc is arranged in a rotationally fixed manner at the vertical upper end of a drive shaft 22 , which extends along the axis of rotation A, supported in an axial bearing 23 . A horizontally arranged crown 24 is arranged on the shaft 22 in a rotationally fixed manner below the grinding disc 20 . The drive device is used to drive the drive shaft 22 , the drive device includes the motor 4 , the transmission device 6 and the shaft 41 connecting the motor 4 with the transmission device 6 . The shaft 41 comprises a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com