Automatic nozzle for spraying concrete in tunnel and construction method thereof

A tunnel spraying and concrete technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., to achieve the effects of reducing labor intensity, compact size, and improving spraying quality and spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

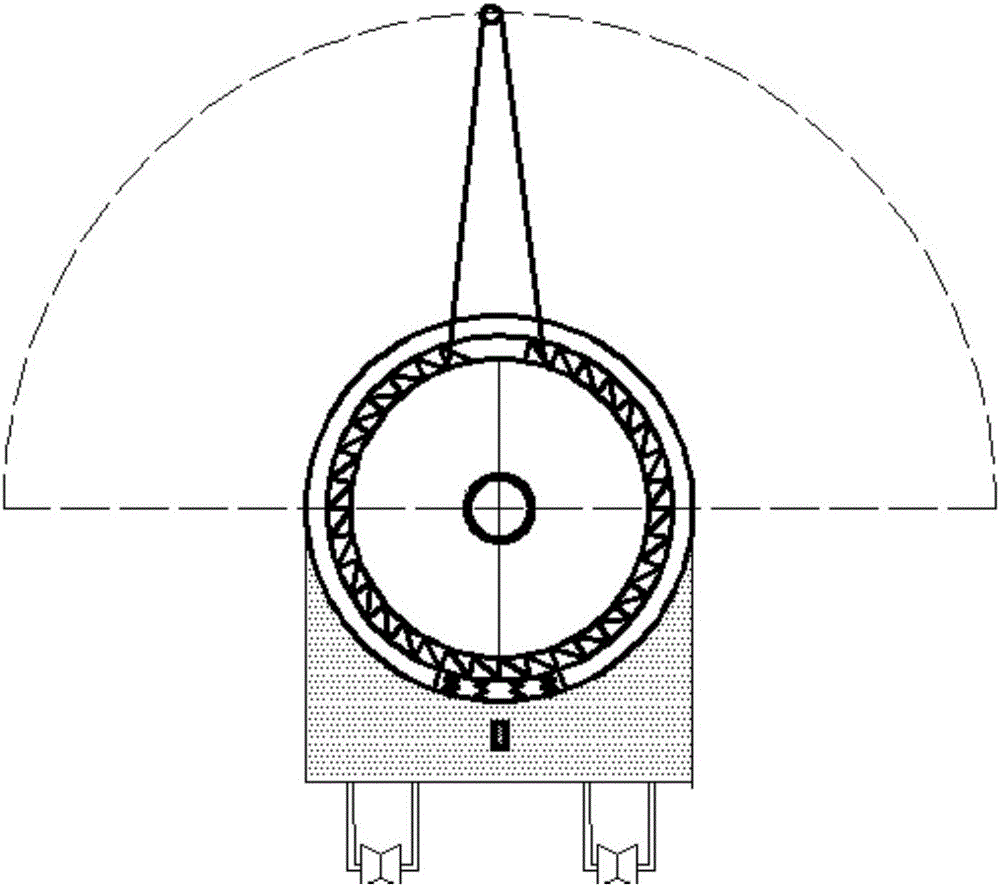

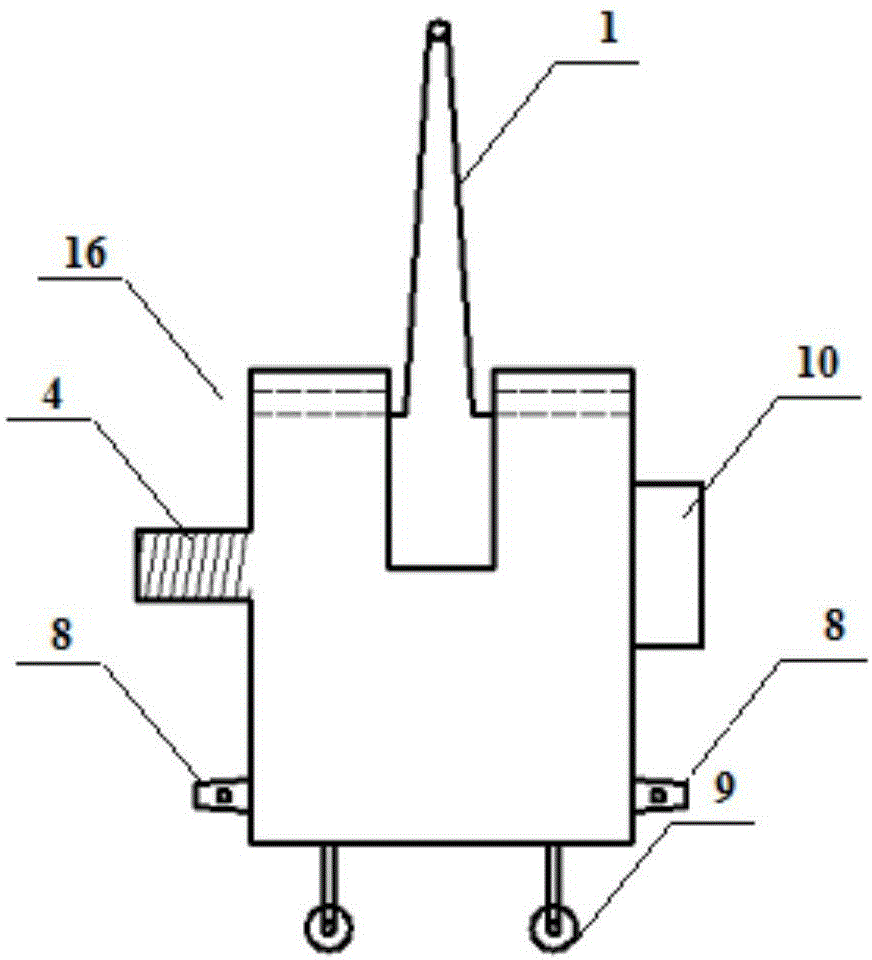

[0039] like Figure 1-7 As shown, an automatic nozzle device for spraying concrete in a tunnel includes a track 14, a nozzle rotating device 2, a fixing device 3, a rotation control system 10 and a power traction device 12;

[0040] The track includes two guide rails 14, which are made of stainless steel and have relatively high rigidity, which can bear the weight of the automatic sprinkler device and the reaction force of spraying grout. The space will not affect the normal construction of other processes, and it will continue to be used until the next spraying cycle.

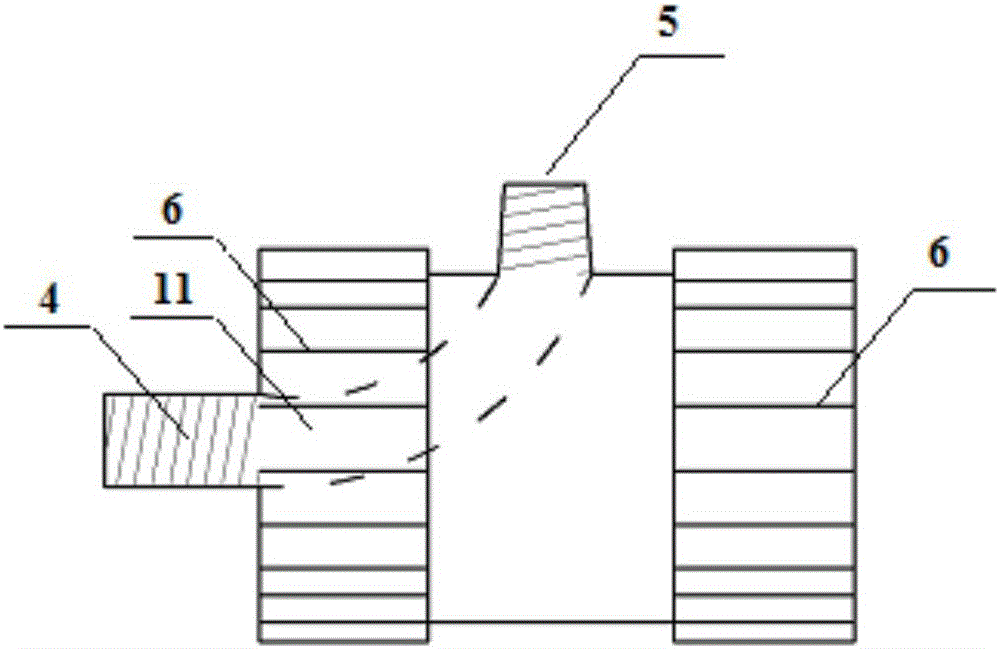

[0041] The nozzle rotating device 2 is embedded in the fixing device 3, which is cylindrical, with threaded interfaces 4 and 5 on the side and top, which can be connected with the spray pipe and nozzle 1 respectively, with a spray channel 11 inside and gears on the outside 6. The gear is rotated under force to realize the rotation of the nozzle connected to it.

[0042] The fixing device 3 is a cylinder slig...

Embodiment 2

[0055] The rotary drive mechanism can also drive the rotary mechanism through gear transmission, chain transmission, worm gear transmission or other similar transmission methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com