Automated Spot Welding Process for Chainsaw Guide Plate

A technology of chainsaw guide plate and spot welding, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of low welding efficiency and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

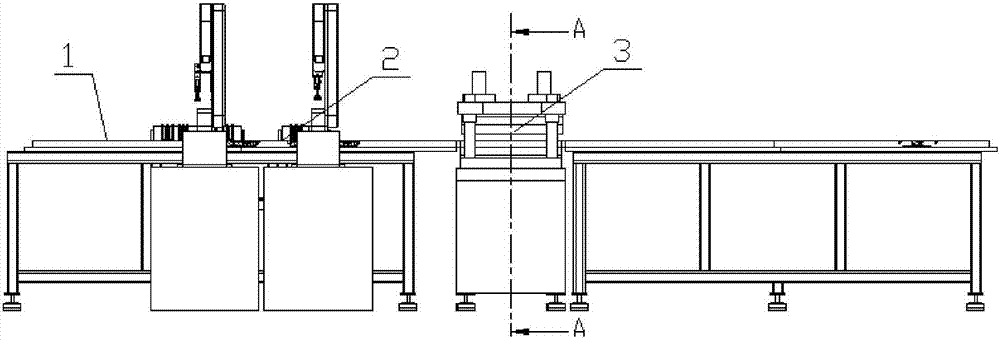

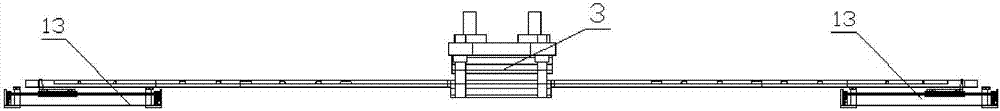

[0036] Such as figure 1 As shown, the chainsaw guide automatic spot welding equipment includes a frame, and a chain saw guide plate dislocation spot welding cycle feeding mechanism 1, a feeding device 2, a spot welding device 3, and a feeding device arranged on the frame.

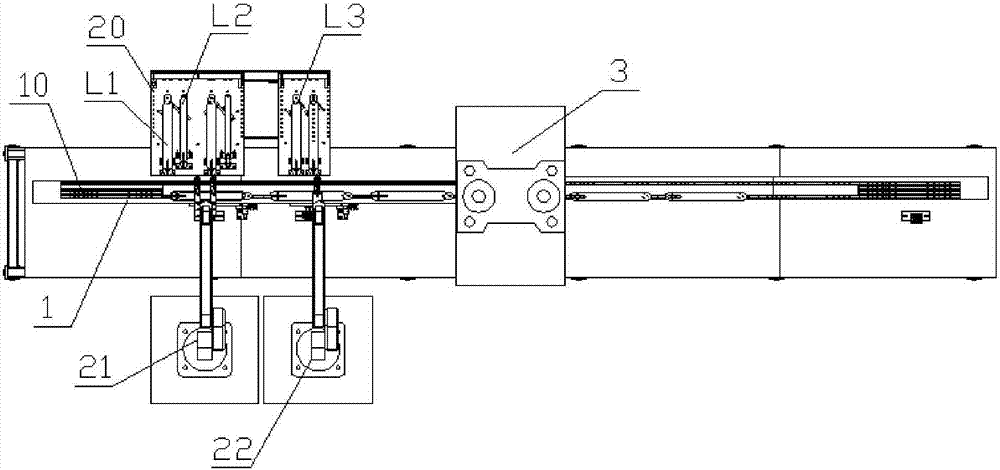

[0037] Among them, such as Figure 2 to Figure 5 As shown, the circular feeding mechanism 1 for chainsaw guide plate dislocation spot welding includes a feeding guide rail 11 , a return guide rail 12 , and a dislocation spot welding guide rod 10 . The misplaced spot welding guide bar 10 is used for clamping the chain saw guide plate, and the chain saw guide plate is composed of the first chain saw guide plate, the second chain saw guide plate and the third chain saw guide plate welded side by side as a whole, so The first chainsaw guide plate, the second chainsaw guide plate, and the third chainsaw guide plate are stacked and positioned and clamped on the misplaced spot welding guide rod 10 and then spot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com