A vacuum fixture automatic adjustment device for polishing workpiece

An automatic adjustment and vacuum clamping technology, which is applied in the control of workpiece feed movement, manufacturing tools, grinding workpiece supports, etc., to achieve the effects of improving processing efficiency, convenient operation, and convenient clamping of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

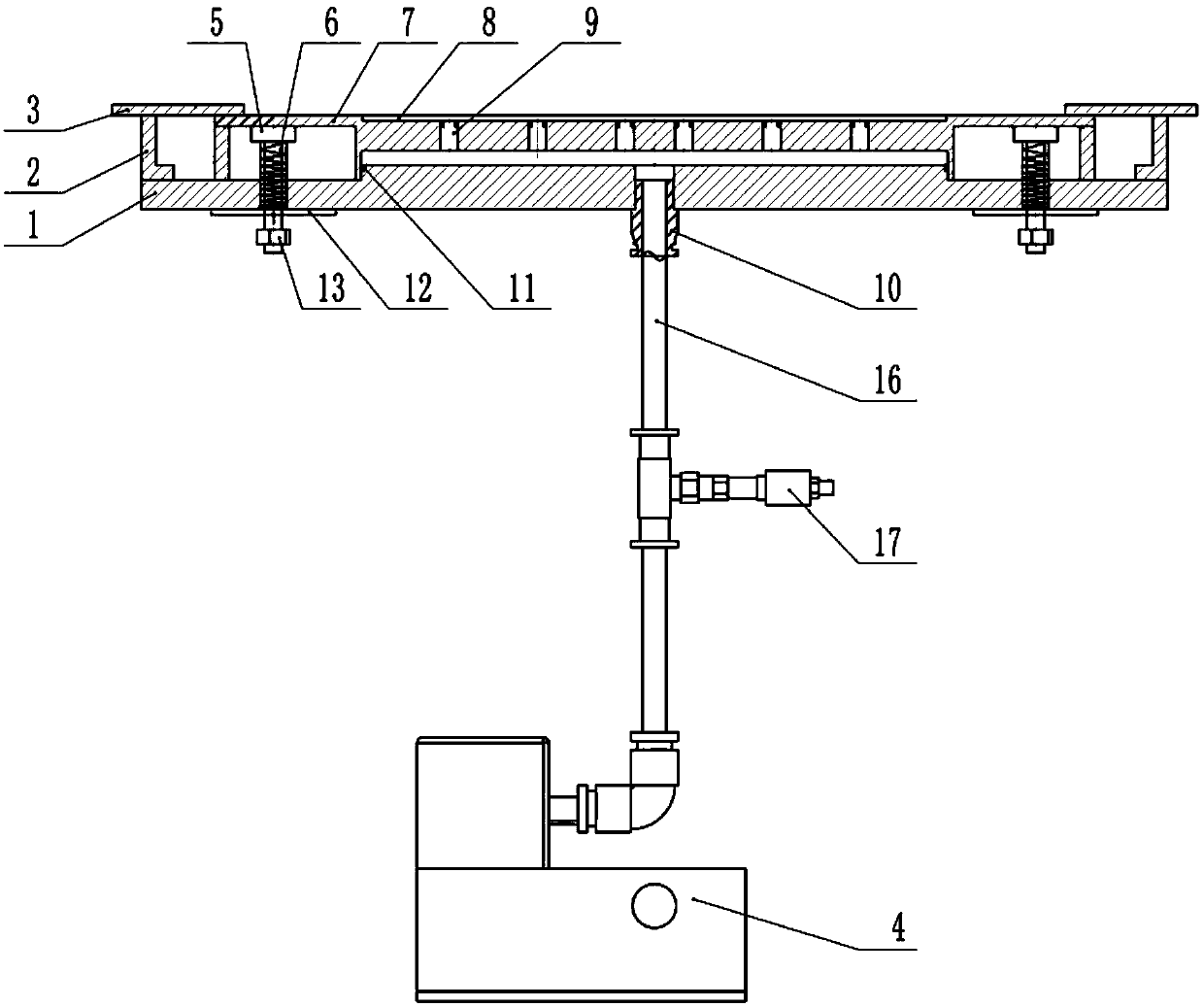

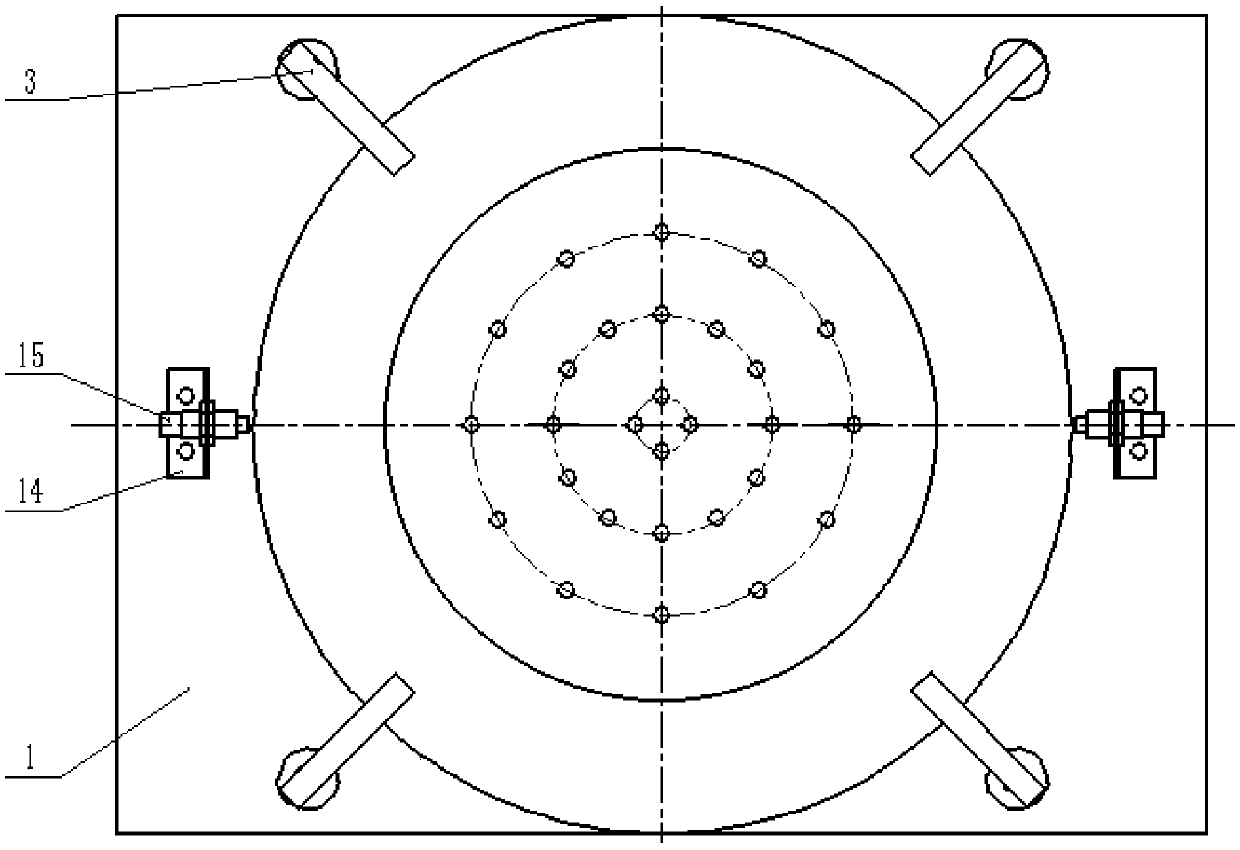

[0020] Such as figure 1 As shown, a vacuum fixture automatic adjustment device for polishing workpieces includes a hydraulic fixing fixture module, a vacuum fixture module and a vacuuming module. The vacuum fixture module includes an upper fixture 7 and a lower fixture 1, and the upper end of the upper fixture 7 is provided with a polishing The circular workpiece mounting groove of the workpiece 8, the bottom of the upper clamp 7 is provided with an upward concave structure, the upper end of the lower clamp 1 is provided with an upward convex structure matching with the upper concave structure, and the upper concave structure of the upper clamp 7 and the lower clamp The convex structure of 1 together forms a sealed cavity, the bottom of the circular workpiece mounting groove is provided with a number of through holes 9 communicating with the cavity, and the bottom of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com