A pre-tensioned prefabricated beam pedestal

A prefabricated beam and pre-tensioning method, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of wasting materials, complex structure, waste of artificial production time and other problems, and achieve a safe, simple structure, and high promotion and use value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

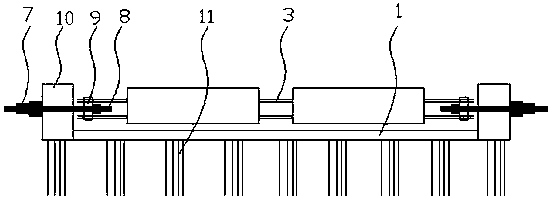

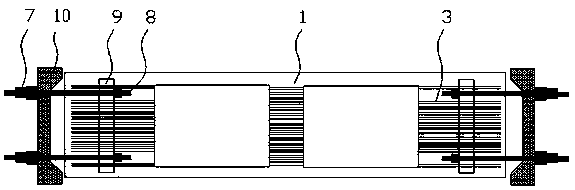

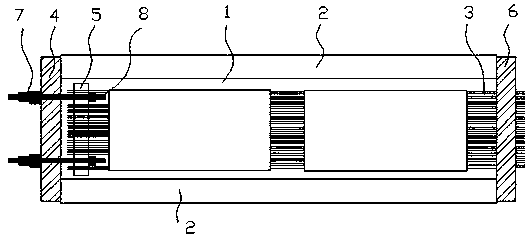

[0030] like image 3 As shown, the pre-tensioned prefabricated beam pedestal includes a rectangular slab base plate 1 and force transmission columns 2, the force transmission columns 2 are arranged in parallel on both sides of the base plate 1, and the two ends of the force transmission column 2 are respectively arranged with fixed-end steel beams 6 and tension The steel beam at the end is connected with a tensioning device on the steel beam at the tensioning end. A steel strand 3 is arranged between the steel beam 6 at the fixed end and the steel beam at the tensioning end. One end of the steel strand 3 is fixed to the steel beam 6 at the fixed end. One end passes through the steel beam at the tensioning end and is connected to the tensioning device. When the tensioning device stretches the steel strand 3, the steel strand 3 moves relative to the steel beam at the tensioning end, so that the steel beam 6 at the fixed end is stretched tightly. At the end of the force transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com