Machining template used for manufacturing flexible micro-hole sound absorbing film and manufacturing method for flexible micro-hole sound absorbing film

A manufacturing method and micromachining technology, applied in the field of vibration reduction and noise reduction, can solve the problem of difficulty in manufacturing a flexible microporous sound-absorbing film that requires acoustic noise reduction, and achieve the effects of simple manufacturing method, small size, and large flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

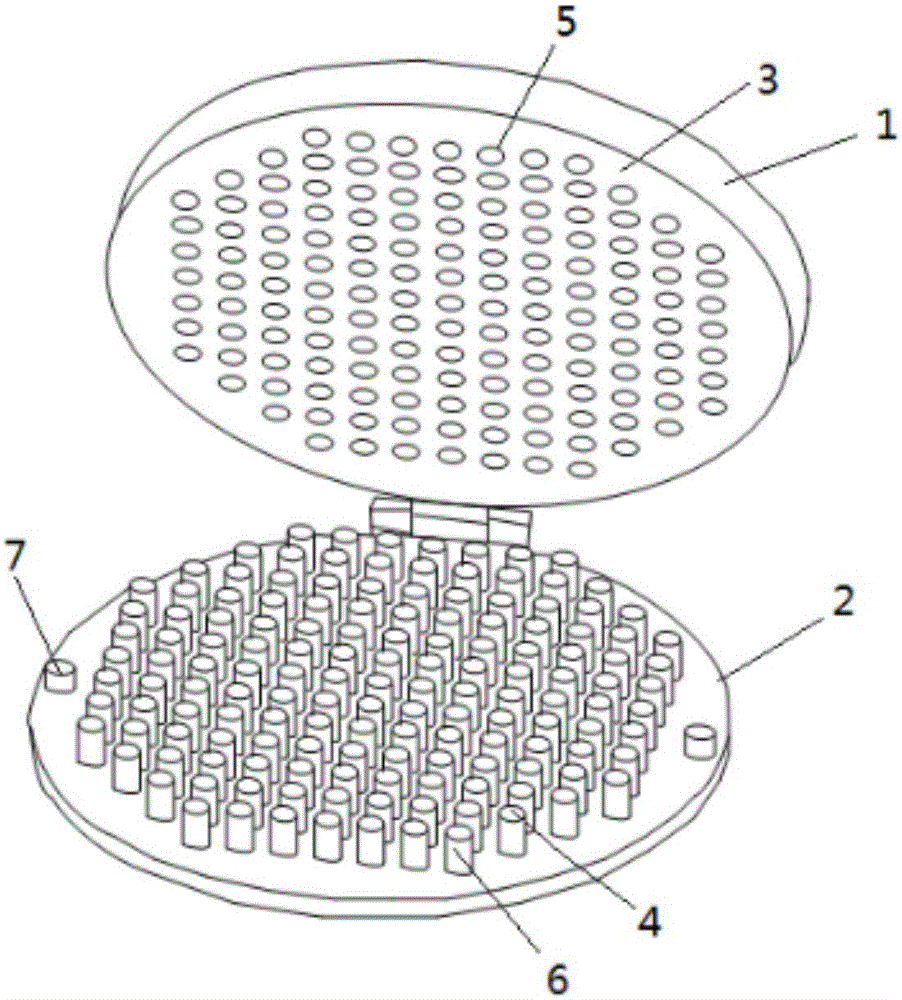

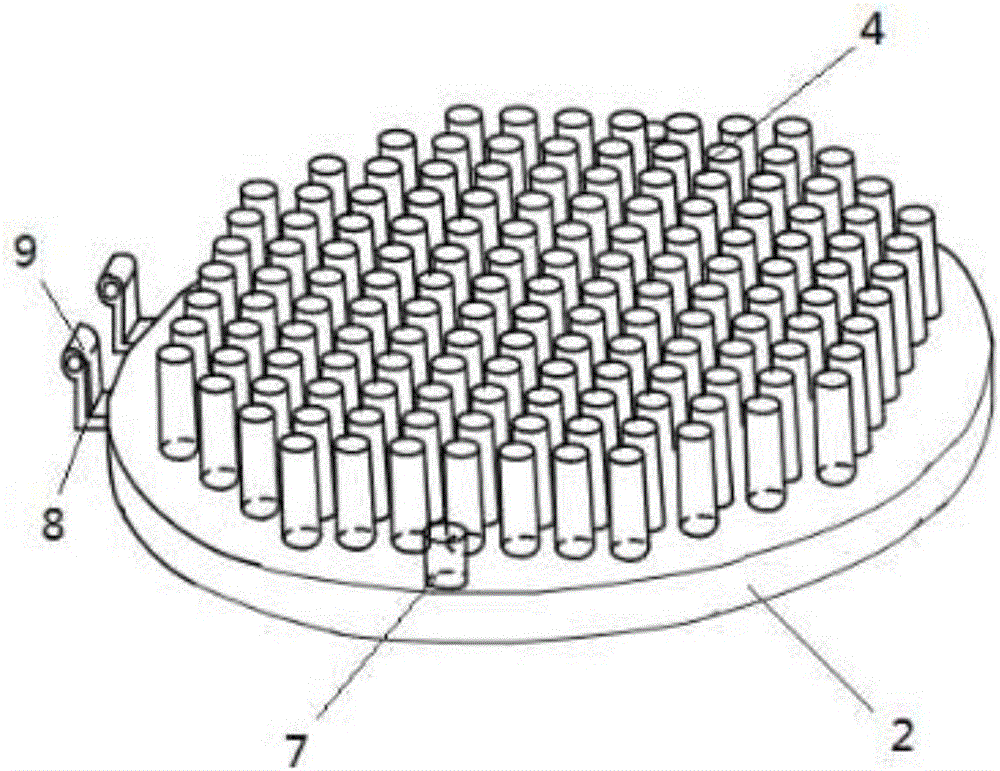

[0060] Such as figure 1 As shown, a processing template for making a flexible microporous sound-absorbing membrane according to the present invention includes an upper template 1 . Such as figure 2 As shown, the lower template 2 is a single template manufacturing method used in the prior art, which has the problems of low porosity and easy adhesion during the manufacturing process. The lower template 2 is provided with a cylinder array 4 , and the cylinder array 4 is an array set composed of a plurality of cylinders 6 .

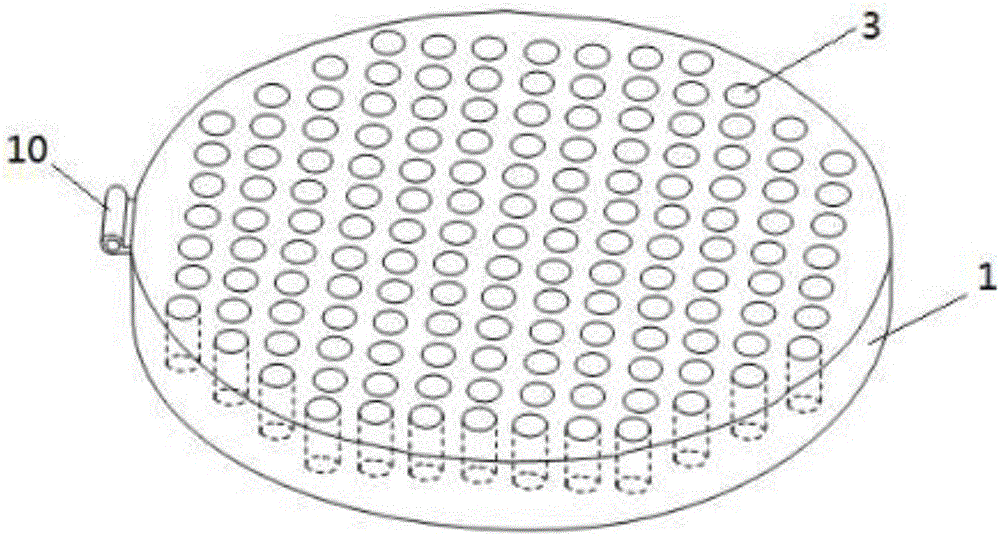

[0061] Such as image 3 As shown, the upper formwork 1 is used to cooperate with the lower formwork 2, and the upper formwork 1 is hinged on the lower formwork 2. The upper template 1 is provided with a round h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com