Composite rubber material and preparation method thereof

A composite material and rubber technology, applied in the field of rubber composite materials, can solve problems such as the inability to effectively meet the noise reduction requirements of reactors, poor mechanical properties and damping properties of nitrile rubber, and achieve the purpose of reducing noise and vibration, improving mechanical properties, The effect of meeting the needs of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

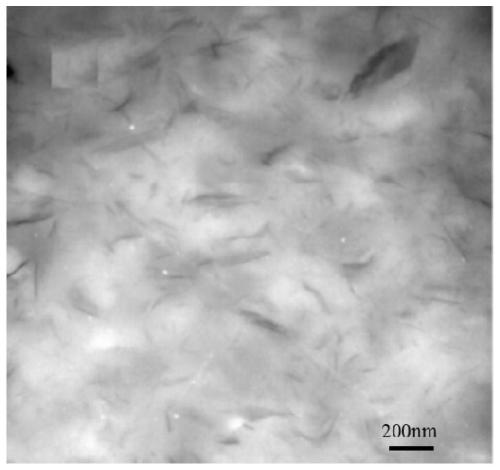

Image

Examples

Embodiment 1

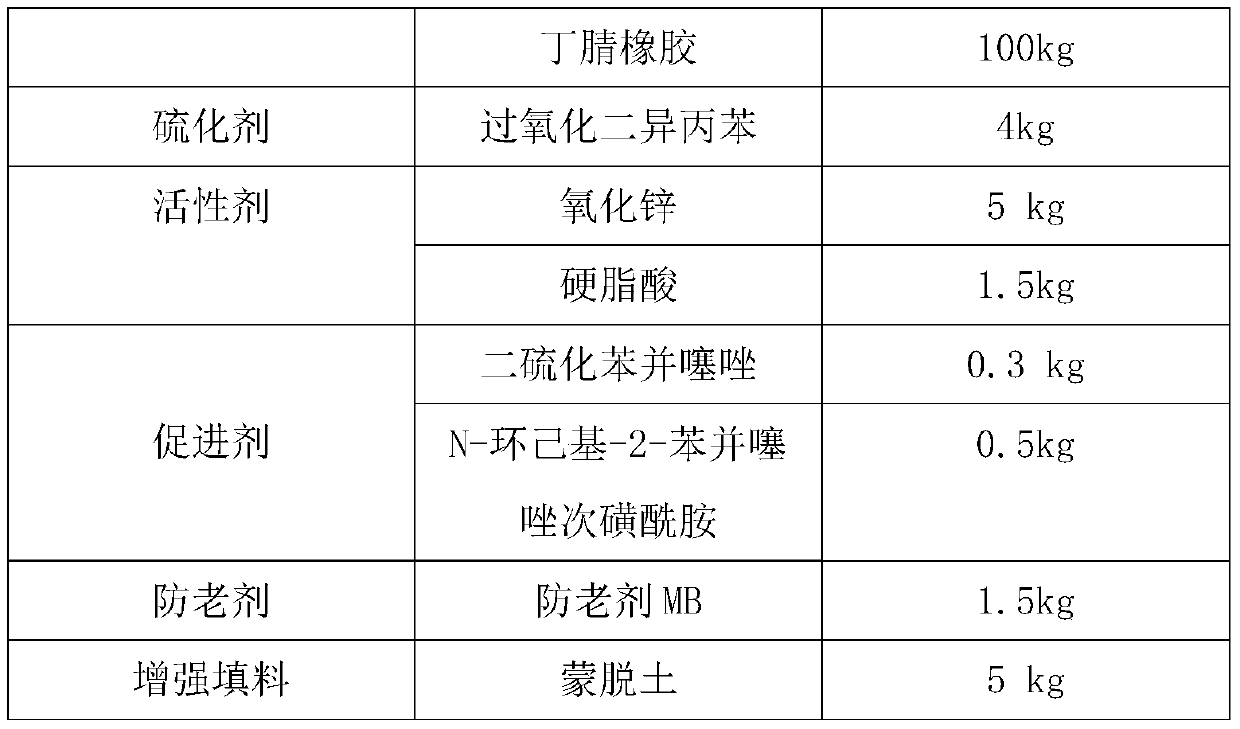

[0037] This embodiment provides an oil-resistant damping sound-insulating rubber composite material for the inner wall of the reactor oil tank, including the following raw materials:

[0038]

[0039] The preparation method of above-mentioned rubber composite material: comprise the steps:

[0040] 1) The nitrile rubber is masticated by the open mill, and the masticated nitrile rubber is coated on the roller, and the active agent, the accelerator, the anti-aging agent, and the reinforcing filler are added to the masticated nitrile rubber in sequence and vulcanizing agent are mixed to obtain rubber compound;

[0041]2) Put the mixed rubber obtained in step 1) for 24 hours, and then use a flat vulcanizer to perform vulcanization and compression molding at a vulcanization temperature of 165° C., a vulcanization pressure of 15 MPa, and a vulcanization time of 20 minutes to obtain the rubber composite material.

Embodiment 2

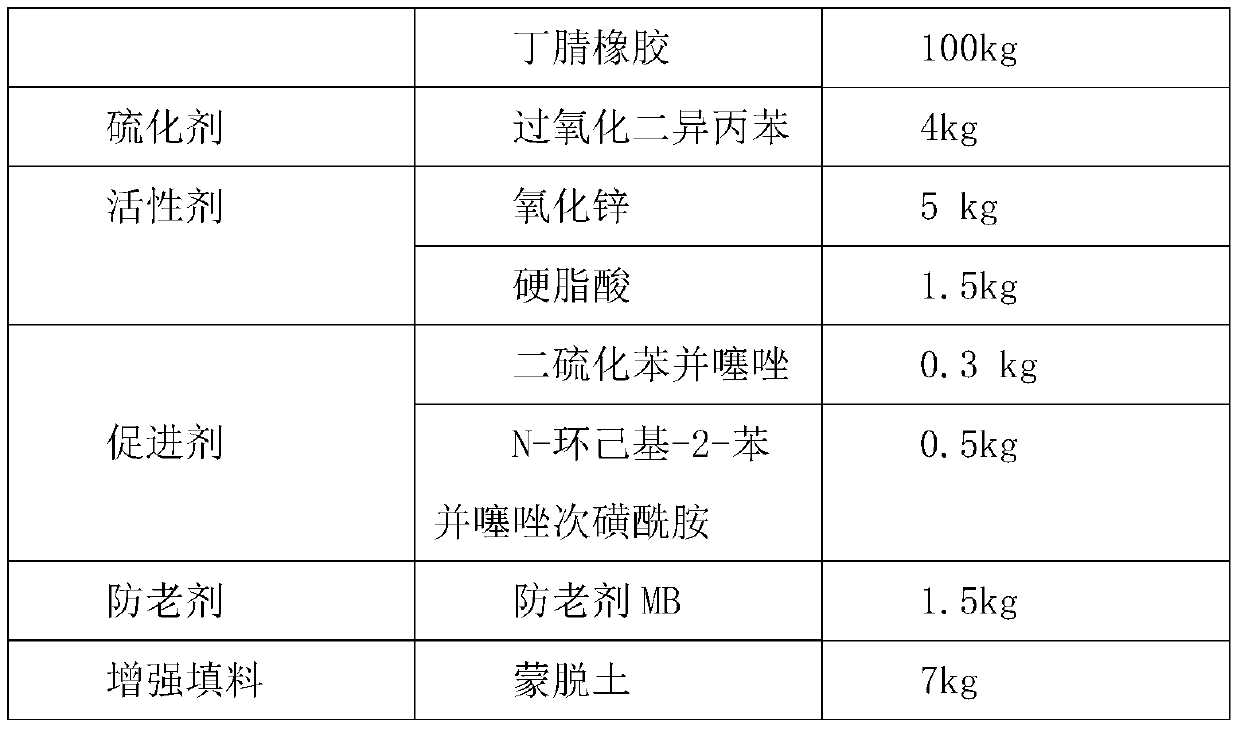

[0043] This embodiment provides an oil-resistant damping sound-insulating rubber composite material for the inner wall of the reactor oil tank, including the following raw materials:

[0044]

[0045] The preparation method of above-mentioned rubber composite material: comprise the steps:

[0046] 1) The nitrile rubber is masticated by the open mill, and the masticated nitrile rubber is coated on the roller, and the active agent, the accelerator, the anti-aging agent, and the reinforcing filler are added to the masticated nitrile rubber in sequence and vulcanizing agent are mixed to obtain rubber compound;

[0047] 2) Put the mixed rubber obtained in step 1) for 24 hours, and then use a flat vulcanizer to perform vulcanization and compression molding at a vulcanization temperature of 165° C., a vulcanization pressure of 15 MPa, and a vulcanization time of 20 minutes to obtain the rubber composite material.

Embodiment 3

[0049] This embodiment provides an oil-resistant damping sound-insulating rubber composite material for the inner wall of the reactor oil tank, including the following raw materials:

[0050]

[0051]

[0052] The preparation method of above-mentioned rubber composite material: comprise the steps:

[0053] 1) The nitrile rubber is masticated by the open mill, and the masticated nitrile rubber is coated on the roller, and the active agent, the accelerator, the anti-aging agent, and the reinforcing filler are added to the masticated nitrile rubber in sequence and vulcanizing agent are mixed to obtain rubber compound;

[0054] 2) Put the mixed rubber obtained in step 1) for 24 hours, and then use a flat vulcanizer to perform vulcanization and compression molding at a vulcanization temperature of 165° C., a vulcanization pressure of 15 MPa, and a vulcanization time of 20 minutes to obtain the rubber composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com