Manufacturing method of wave-eliminating yacht

A manufacturing method and technology for speedboats, which are applied in the directions of ships, ship construction, and ship parts, can solve the problems of seasickness, many welding points, poor stability, etc., and achieve the effects of simple and easy manufacturing, less labor, and fewer welding points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

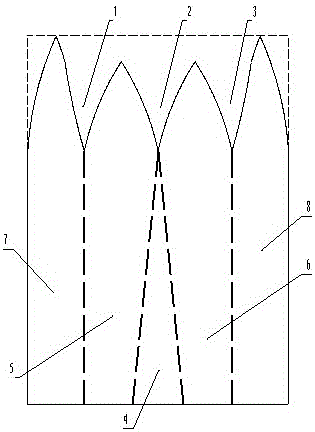

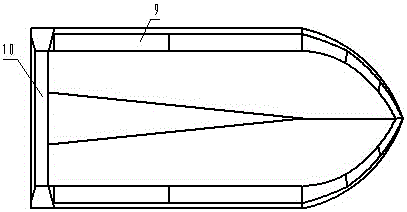

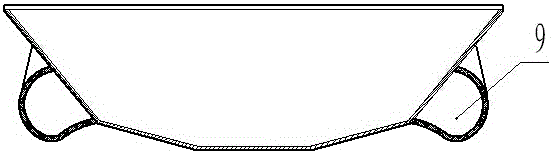

[0019] Such as figure 1 , figure 2 with image 3 Shown embodiment, its manufacture method comprises the steps:

[0020] A. Cut out three "V"-shaped notches 1, 2, and 3 at intervals along the length direction of the front end of the rectangular metal plate;

[0021] B. Press and fold a triangular plate 4 longitudinally along the tip of the “V”-shaped notch 2 on the metal plate to the back section of the metal plate, and then edge two other “V”-shaped notches 1, 3 on both sides of the triangular plate The tip of the sloping plate is pressed and folded out of the inclined plates 5 and 6 longitudinally, and the two inclined plates and the triangular flat plate constitute the bottom plate of the hull; then the outer sides 7 and 8 of each inclined plate are folded vertically upward to form the hull; The buoys 9 are welded on the knuckle lines on both sides of the hull, and the buoys are closed long tanks with cavities inside, and the bottom of the outer side of the long tanks is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com