Overheating destructive switch

a technology of destructive switch and overheating, which is applied in the direction of thermal switch details, tumbler/rocker switch details, coupling device connection, etc., can solve the problems of excessive energy consumption, poor conductivity of fuse, and excessive energy consumption, so as to increase the size of the switch, the overall structure is simple and easy to manufacture, and the current transmission of the electrical appliance or the extension cord is not hampered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

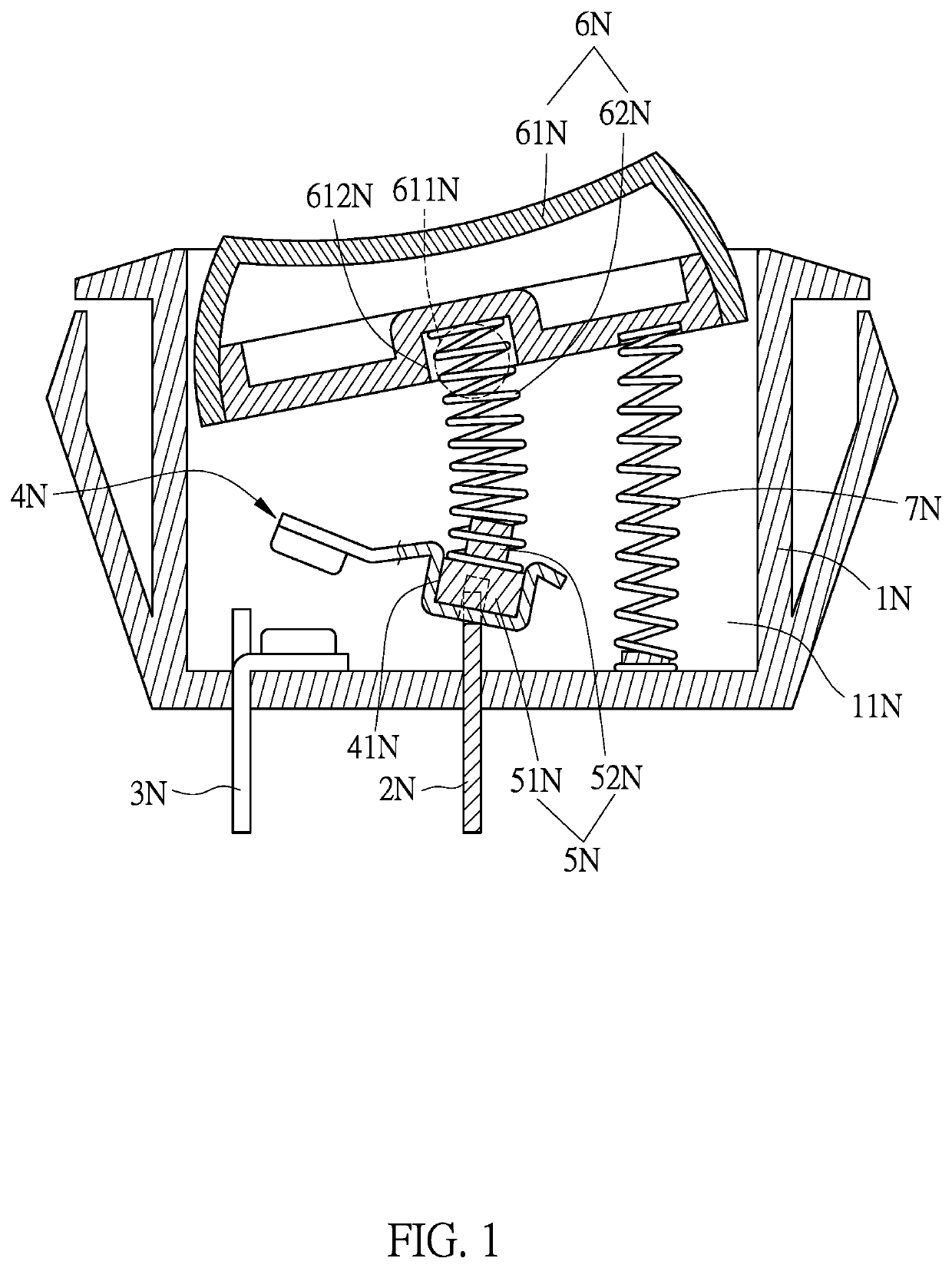

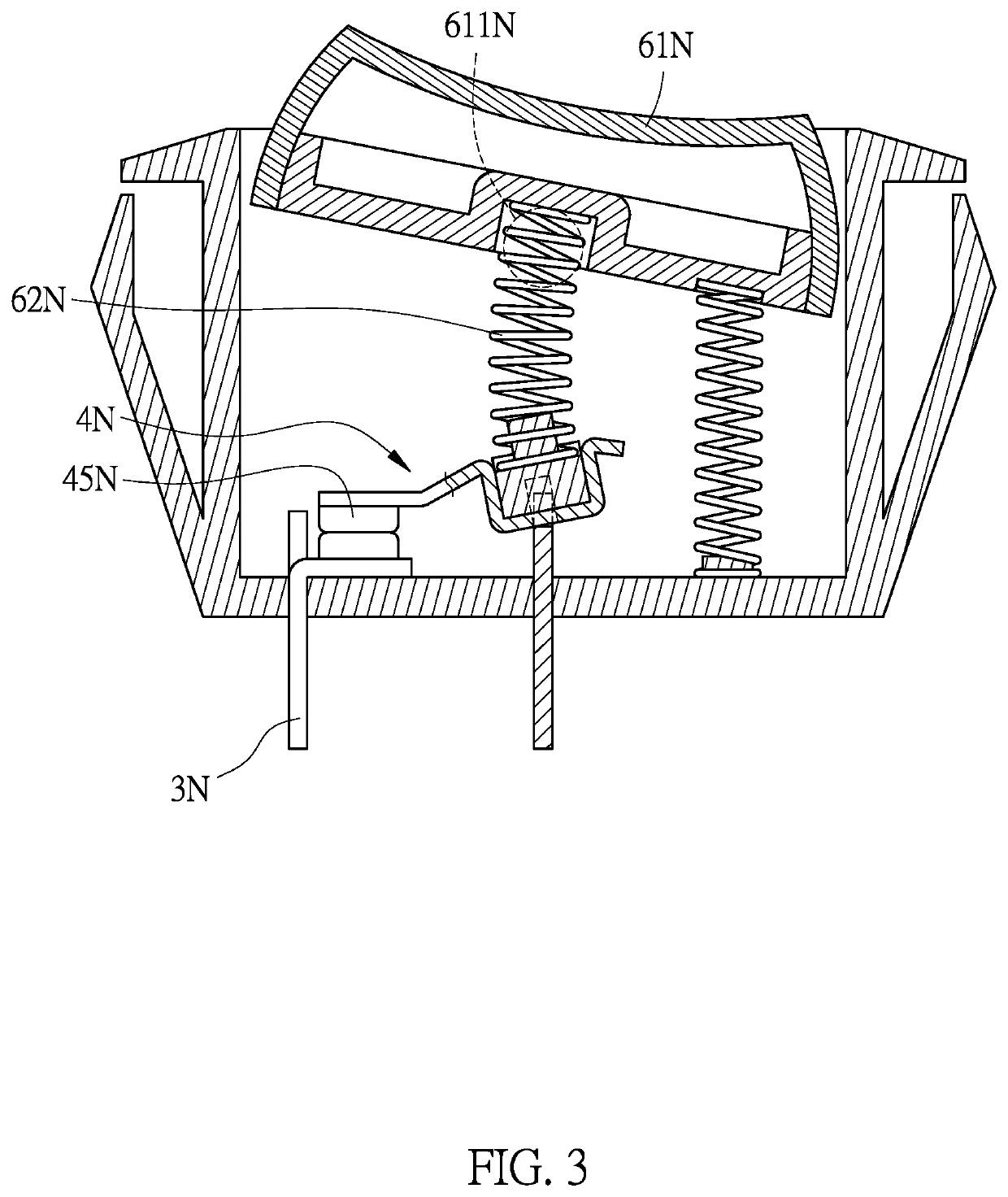

[0051]Referring to FIG. 1 for the present invention, an overheating destructive switch of the embodiment is in a form of a rocker switch, wherein FIG. 1 shows that the rocker switch is in a disconnected state.

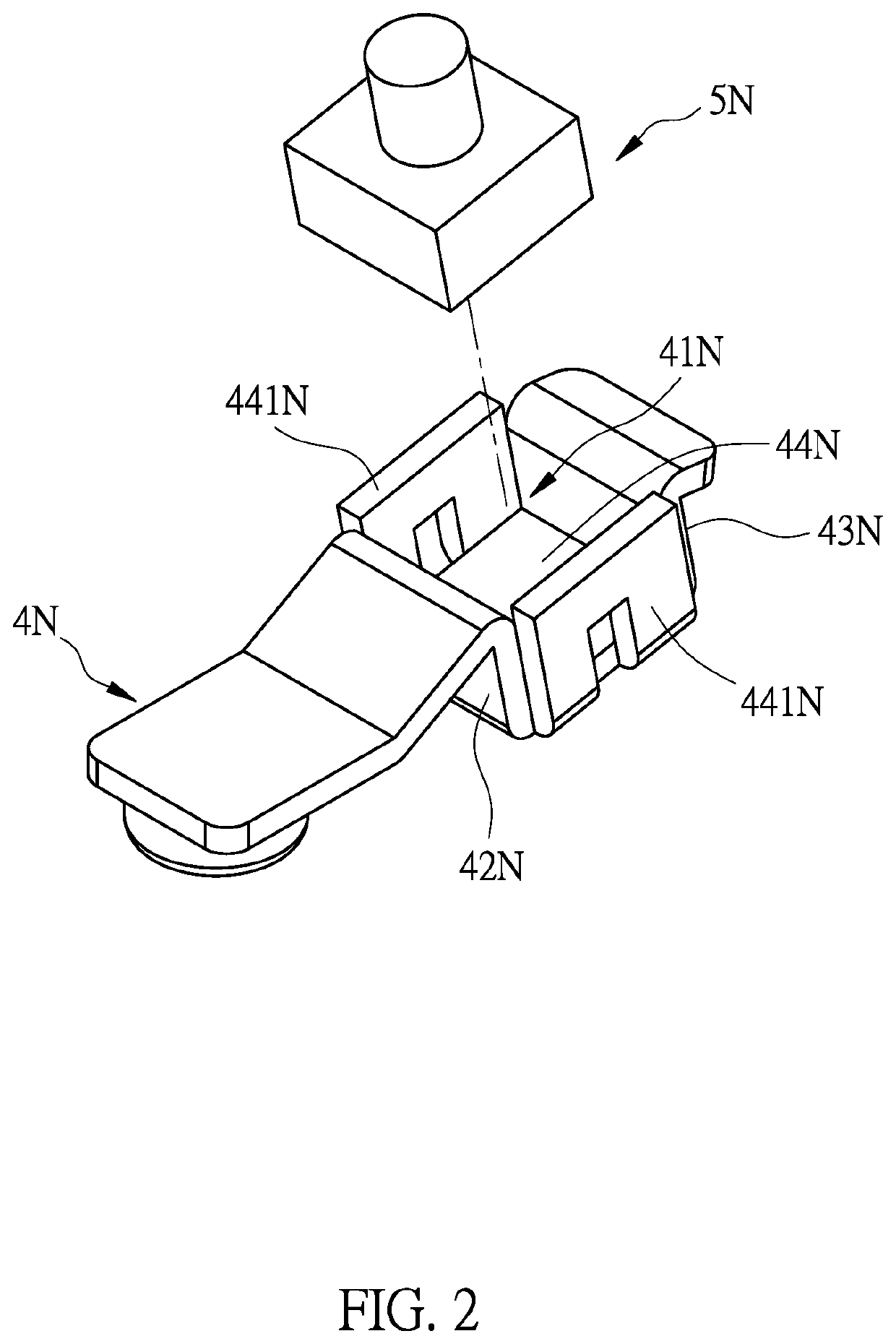

[0052]The rocker switch comprises: a base (1N) having a receiving space (11N); a first conductive element (2N) and a second conductive element (3N) penetrated into and provided in the base (1N); a movable conductive element (which can be referred to as a rocker conductive element (4N) in this embodiment) provided in the receiving space (11N); an overheating destructive element (5N); an operating component (6N) assembled on the base (1N), wherein the operating component (6N) comprises an operating element (61N) and a first elastic element (62N); and a second elastic element (7N). In which:

[0053]the rocker conductive element (4N) is provided over the first conductive element (2N) and electrically connected to the second conductive element (3N). The overheating destructive element...

fourth embodiment

[0060]Referring to FIG. 10 for the present invention, an overheating destructive switch is shown in the embodiment and is in a form of a push switch, wherein FIG. 10 shows that the push switch is in a disconnected state.

[0061]The push switch comprises:

[0062]a base (1R) having a receiving space (11R) and a protruding portion (12R); a first conductive element (2R) and a second conductive element (3R) penetrated into and provided in the base (1R); a movable conductive element provided in the receiving space (11R), wherein the movable conductive element is a conductive cantilever element (4R); an overheating destructive element (5R) which can be destroyed at a destructive temperature, wherein the destructive temperature is between 100° C. to 250° C. The overheating destructive element (5R) is not used to maintain the continuous supply of currents, and thus can be selectively made of an insulative material such as a plastic but is not limited thereto, and can also be selected from a non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com