Multi-section leakage-blocking device

A multi-stage, leak-stopping technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of high risk, not enough to deal with emergency situations, poor leak-stopping effect, etc., and achieve the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and embodiments.

[0016] Before the present invention is described in detail, it should be noted that the relative position terms used in the following description, such as "inner" and "outer" are based on the normal use orientation and the orientation shown in each figure.

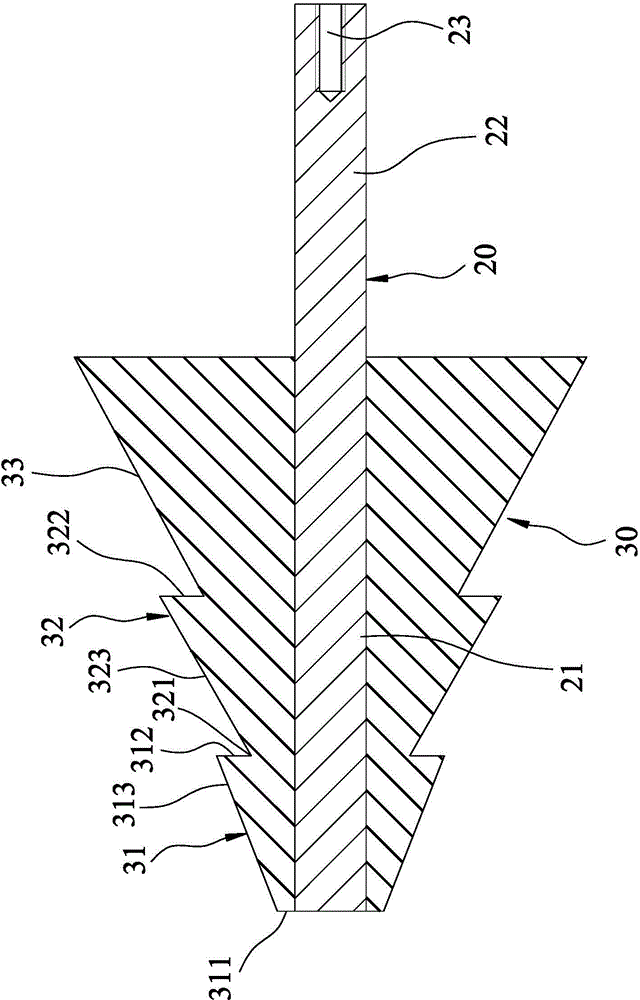

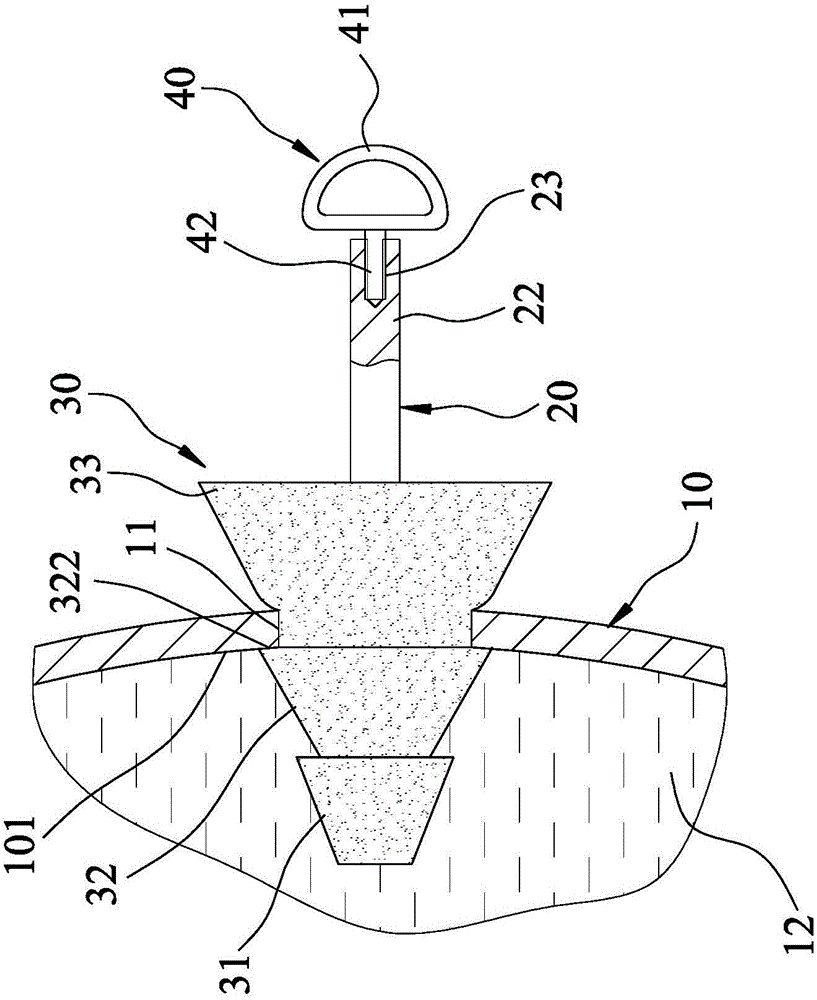

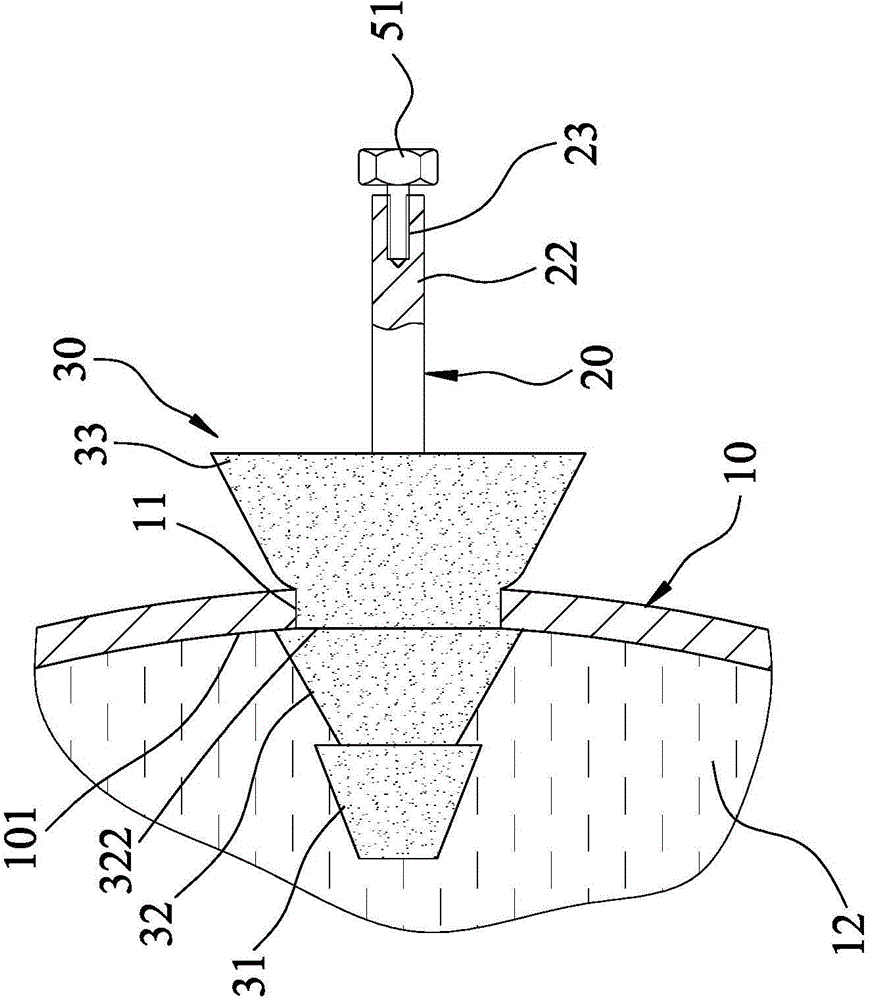

[0017] Such as figure 1 , figure 2 , Figure 4 As shown, an embodiment of the multi-stage leakage prevention device of the present invention is used to install in a liquid storage tank 10, and the embodiment includes a plunger 20, a blocking unit 30, a handle 40 and a fixing unit 50.

[0018] The inserting rod 20 includes an inserting section 21 and an exposed section 22 located in opposite directions, and a screw hole 23 disposed on the exposed section 22 along the axial direction of the inserting rod 20.

[0019] The blocking unit 30 includes a first blocking member 31 and a second blocking member 32 fixed on the inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com