Thick-film hybrid integrated circuit surface enveloping process

A hybrid technology of integrated circuits and thick films, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve the problems of device or line breakage and early product failure that affect product service life, expansion coefficient and ceramic characteristics. problem, achieve the effect of saving time, superior insulation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A thick-film hybrid integrated circuit surface encapsulation process, the process method is: at normal temperature and 40-60% humidity, immerse the thick-film hybrid integrated circuit in the encapsulation liquid with a jig, take it out into a curing furnace and dry it with the jig , the encapsulation solution is composed of novolac epoxy resin, ethanol and acetone, the processing method is: after mixing 15kg of ethanol and 15kg of acetone, add 100kg of novolac epoxy resin.

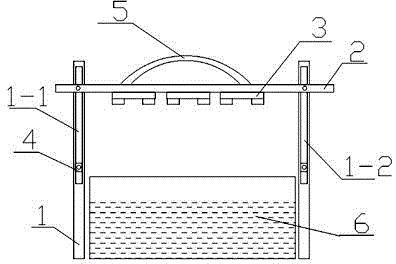

[0011] The clamp is composed of a bracket 1, a slide bar 2, a set of clamps 3 and two limit blocks 4. The two ends of the bracket 1 are respectively provided with chute 1-1 and chute 1-2, and the two ends of the slide bar 2 are respectively passed through bolts It is movably installed in the chute of the bracket 1, a set of clamps 3 is movably installed on the slide bar 2, and two limit blocks 4 are movably installed in the chute 1-1 and the chute 1-2 of the bracket 1 respectively.

[0012] It also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com